Wholesale Filter Drier on Suction Line - Manufacturers & Factories

The Filter Drier on the suction line is an essential component for maintaining the efficiency and longevity of refrigeration and air conditioning systems. Designed to remove moisture, particulate contamination, and acids, this product ensures the smooth operation of your cooling system. By strategically placing the filter drier on the suction line, it prevents harmful substances from entering the compressor, thereby reducing wear and tear, Ningbo Senjun New Materials Co., Ltd. is committed to delivering high-quality filter driers that meet international standards. Our products are crafted with advanced materials and cutting-edge technology, ensuring optimal performance and reliability. The robust design allows for easy installation and maintenance, making it an ideal choice for both residential and commercial applications. Trust in our expertise to enhance the reliability of your HVAC systems and secure a comfortable environment. With Ningbo Senjun’s Filter Drier, experience improved efficiency and reduced risk of system failures

How To Evaluate Filter Drier On Suction Line Factory For the Current Year

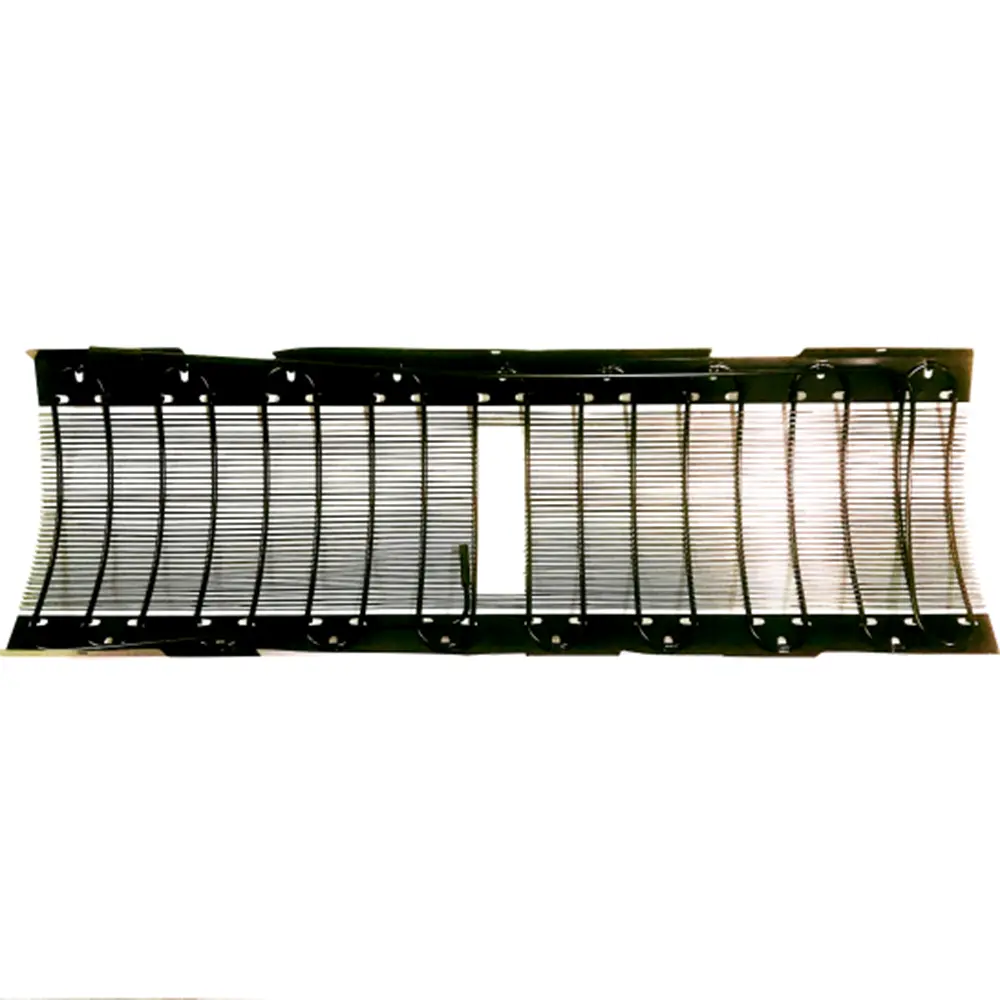

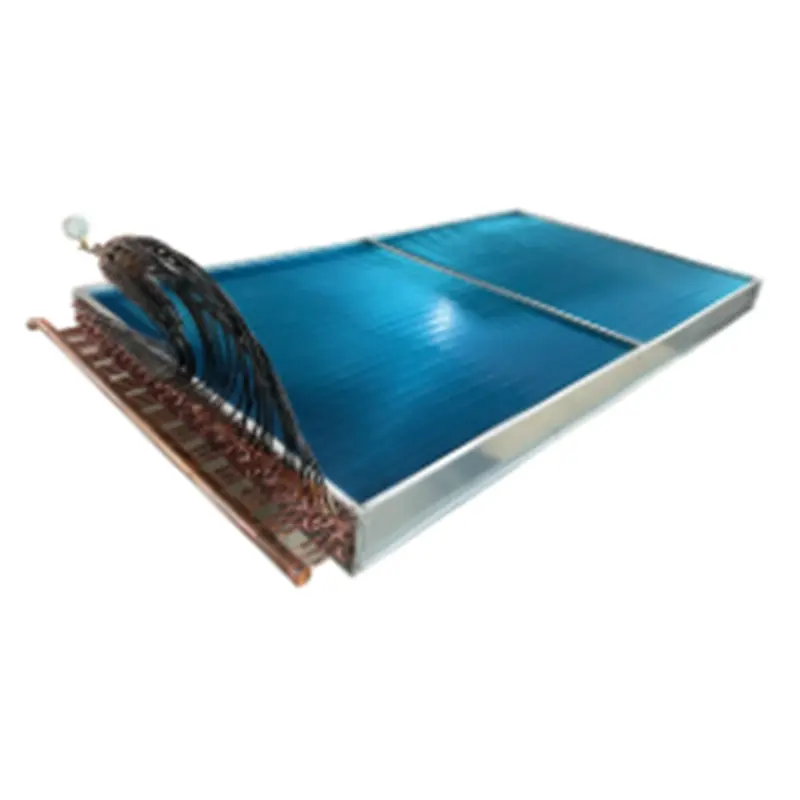

When evaluating filter driers on the suction line for your manufacturing needs in the current year, it’s important to consider both efficiency and reliability. As global supply chains evolve, ensuring that you have the right components can significantly impact the performance and longevity of equipment such as refrigerators, freezers, and display cabinets. At Ningbo Senjun New Materials Co., Ltd., established in 2010, we specialize in producing high-quality wire tube condensers and copper aluminum fin heat exchangers that enhance the effectiveness of your refrigeration systems. Filter driers play a vital role in protecting your refrigeration systems by removing moisture and contaminants. When sourcing filter driers, look for brands that meet industry standards for performance and durability. Assess the materials used, such as aluminum and copper, as they influence thermal conductivity and overall efficiency. Additionally, partnering with a reliable supplier like Ningbo Senjun ensures that you receive expertly engineered products designed for optimal integration with your current systems, providing both quality assurance and peace of mind. In conclusion, as you navigate the complexities of global procurement in 2023, prioritize products that enhance your equipment's efficiency and sustainability. By collaborating with established manufacturers like Ningbo Senjun, you not only gain access to innovative solutions but also a trusted partner invested in your success in the competitive refrigeration market.

How To Evaluate Filter Drier On Suction Line Factory For the Current Year

| Dimension | Value | Unit | Remarks |

|---|---|---|---|

| Filter Drier Capacity | 90 | CFM | Suitable for residential applications |

| Max Operating Pressure | 350 | PSI | Ensure safety standards |

| Refrigerant Compatibility | R-410A | Type | Commonly used in modern systems |

| Dimensions | 12 x 4 | Inches | Compact size for easy installation |

| Weight | 3.5 | Pounds | Lightweight for handling |

| Filtration Efficiency | 99.9 | % | High efficiency for better performance |

Discovering Filter Drier On Suction Line Service Backed by Expertise Leads the Global Market

J

Jessica Patel

The quality of the item is remarkable! Plus, the customer service was so professional and helpful throughout the entire process.

05 July 2025

T

Thomas Brown

I can’t praise this product enough! The quality is remarkable, and the after-sales service has been incredibly supportive.

12 June 2025

C

Chloe King

I’m very pleased with this product! The quality is exceptional, and the after-sales service was outstanding.

16 May 2025

B

Benjamin Graves

The quality is excellent! The customer service team was friendly and very communicative.

08 June 2025

A

Alexander Murphy

A truly wonderful experience! The quality of this product is exceptional, and the service was fast and friendly.

07 June 2025

S

Scarlett Martinez

This product is of outstanding quality! The after-sales support staff were knowledgeable and eager to help.

18 June 2025