Condenser Plate Heat Exchanger Manufacturer in China - Quality Factory Solutions

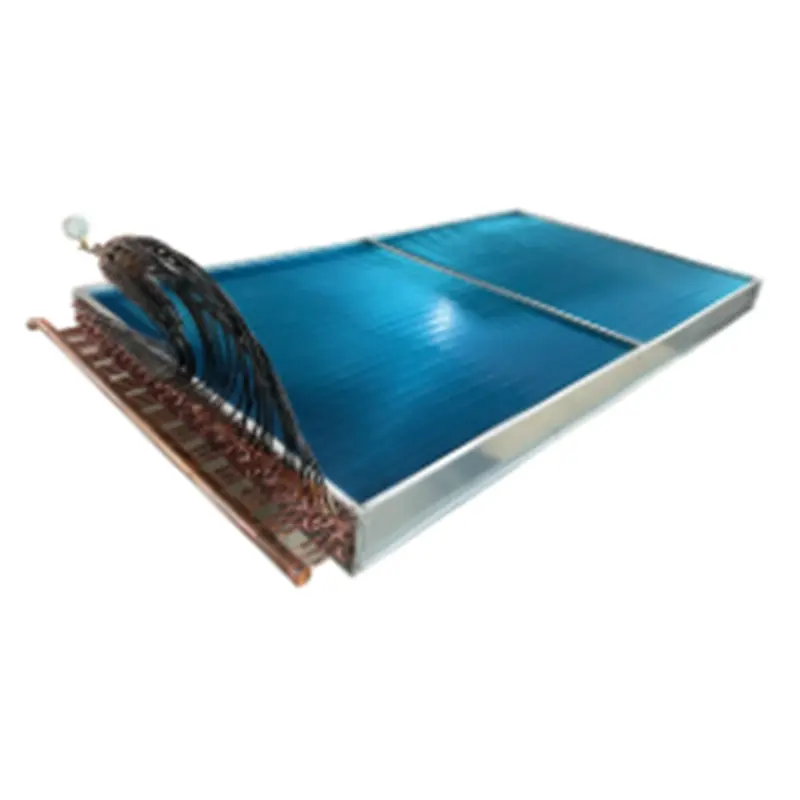

Ningbo Senjun New Materials Co., Ltd. proudly presents its state-of-the-art Condenser Plate Heat Exchanger, designed for optimal thermal efficiency and reliable performance. These heat exchangers utilize advanced plate technology, enabling superior heat transfer characteristics while occupying a minimal footprint. Ideal for a variety of applications, from HVAC to industrial processes, our condenser models ensure effective cooling and heat recovery, reducing energy consumption and operational costs, Crafted from high-quality materials, the heat exchangers exhibit excellent corrosion resistance and durability, ensuring long-term reliability even in challenging environments. The innovative design allows for easy maintenance and customization, making them suitable for diverse operational needs, With a commitment to excellence, Ningbo Senjun New Materials Co., Ltd. leverages cutting-edge manufacturing techniques and rigorous testing standards to deliver products that exceed industry expectations. Experience enhanced performance and sustainability with our Condenser Plate Heat Exchanger, the perfect solution for efficient heat management in your systems

Best Methods To Condenser Plate Heat Exchanger Pioneers in the Field Factory-Direct Excellence

When it comes to selecting high-quality condenser plate heat exchangers, Ningbo Senjun New Materials Co., Ltd. stands out as a pioneer in the field. Since our establishment in 2010, we have dedicated ourselves to innovating and producing advanced wire tube condensers and copper aluminum fin heat exchangers, specifically designed for refrigerators, freezers, drinking fountains, display cabinets, and more. Our commitment to excellence and factory-direct operations allow us to provide unparalleled products that meet the demands of modern applications while ensuring cost-effectiveness and reliability. Our expertise in research and development enables us to create heat exchangers that excel in efficiency and performance. We prioritize the needs of our global buyers by incorporating cutting-edge technologies and adhering to strict quality standards. With a focus on sustainability, our products not only enhance the cooling process but also contribute to energy conservation efforts across various industries. By choosing Ningbo Senjun, you are investing in superior technology that promises durability and efficiency. Whether you are a manufacturer seeking reliable components or a distributor looking to expand your product range, our comprehensive solutions and professional support will empower your business. Discover the excellence of our factory-direct offerings that deliver both high performance and competitive pricing. Explore the best methods for maximized efficiency with Ningbo Senjun, your trusted partner in the heat exchanger industry.

Best Methods To Condenser Plate Heat Exchanger Pioneers in the Field Factory-Direct Excellence

| Method | Efficiency (%) | Heat Transfer Rate (kW) | Application |

|---|---|---|---|

| Counterflow Design | 85% | 150.0 | Industrial Cooling |

| Crossflow Design | 75% | 120.0 | HVAC Systems |

| Hybrid Plate Design | 90% | 200.0 | Food Processing |

| Plate Material Upgrade | 80% | 170.0 | Chemical Processing |

| Optimized Flow Configuration | 88% | 180.0 | Power Generation |

Simple Ways To Condenser Plate Heat Exchanger Leads the Global Market Supplies the World’s Top Brands

M

Megan Lewis

I’m very happy with my purchase. The product quality is superb, and the after-sales service was incredibly helpful.

10 May 2025

E

Elijah Ramirez

I’m very satisfied with my purchase! The product quality is excellent, and the customer service was very helpful.

17 June 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

M

Maddison Reed

Fantastic quality and superb support! The after-sales team really knows their stuff.

15 June 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

N

Noah Gonzalez

Very happy with my purchase! The product is top quality, and the customer support was very helpful.

22 May 2025