Top China Condenser Heat Transfer Manufacturers & Suppliers Factory

As a leading supplier in the Condenser Heat Transfer sector, I take pride in offering high-quality products tailored for your needs. Our factory, located in Ningbo, China, specializes in the production of efficient heat transfer solutions that cater to diverse industries. With years of experience under our belt, I understand the importance of reliable performance and durability in Heat Exchangers

Best Strategies For Condenser Heat Transfer Manufacturers Dominates Sets the Industry Standard

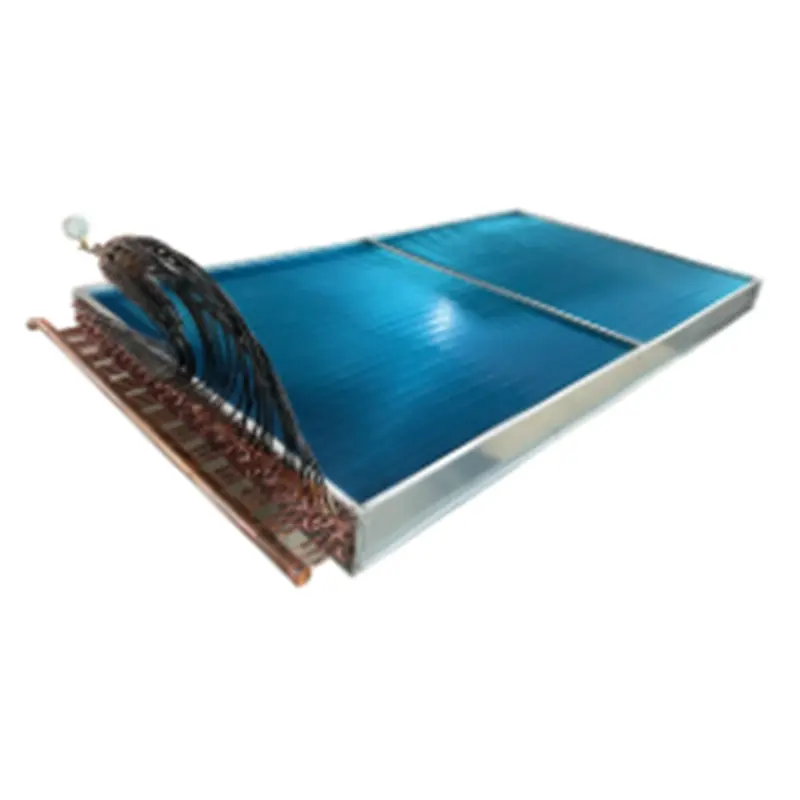

In the ever-evolving landscape of heat transfer technology, Ningbo Senjun New Materials Co., Ltd. stands as a beacon of innovation and reliability. Founded in 2010, our company has diligently focused on the research, development, and production of advanced wire tube condensers and copper-aluminum fin heat exchangers, specifically designed for various applications including refrigerators, freezers, drinking fountains, and display cabinets. As a leading manufacturer in the industry, we are committed to setting the highest standards for quality and efficiency, ensuring that our products meet the diverse needs of global buyers. Understanding the importance of effective heat transfer in modern appliances, we have refined our production processes to maximize thermal performance while minimizing environmental impact. Our state-of-the-art facilities in Ningbo leverage cutting-edge technology and skilled expertise, allowing us to deliver products that not only enhance energy efficiency but also guarantee durability and longevity. By fostering strong partnerships with suppliers and clients alike, we strive to stay ahead of industry trends and respond swiftly to market demands. For global procurement specialists seeking reliable heat transfer solutions, selecting Ningbo Senjun New Materials Co., Ltd. means choosing a partner dedicated to excellence. Our commitment to innovation, quality control, and customer satisfaction positions us at the forefront of the industry, making us the preferred choice for businesses aiming to optimize their operations and enhance product performance. Connect with us today to discover how our advanced cooling solutions can elevate your product offerings and drive your success in the market.

Best Strategies For Condenser Heat Transfer Manufacturers Dominates Sets the Industry Standard

| Strategy | Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| Optimized Material Selection | Using high thermal conductivity materials to improve heat transfer rates. | Increased efficiency and reduced operational costs. | 3-6 months |

| Advanced Manufacturing Techniques | Implementing precision machining and additive manufacturing for better product quality. | Higher product durability and customer satisfaction. | 6-12 months |

| Enhanced Testing Protocols | Developing rigorous testing standards to ensure product reliability. | Reduced failure rates and enhanced market reputation. | 1-3 months |

| Energy Efficiency Focus | Designing condensers with energy-saving features to meet regulations. | Lower energy consumption and compliance with energy standards. | 1-2 years |

| Research and Development Investment | Allocating funds to innovate new heat transfer technologies. | Increased competitive advantage and longer product lifecycle. | Ongoing |

10 Essential Tips For Condenser Heat Transfer Manufacturers Manufacturers You Can Rely On Sets the Industry Standard

R

Rachel Green

Quality and service are both exceptional! I received prompt assistance from the support team, which made my experience even better.

28 June 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

I

Isabella Foster

Remarkable quality! The support staff is educated and attentive, making the entire process seamless.

28 May 2025

L

Liam Bennett

I’ve had nothing but a positive experience! The product is of excellent quality and service team is very helpful.

15 June 2025

E

Ella Murphy

I’m very pleased! The product quality is outstanding and the after-sales support was excellent.

21 May 2025

J

Joshua Campbell

Fantastic craftsmanship! The after-sales service was prompt and the staff was very competent.

08 May 2025