China Condenser Evaporator Heat Exchanger Factory - Top Manufacturers

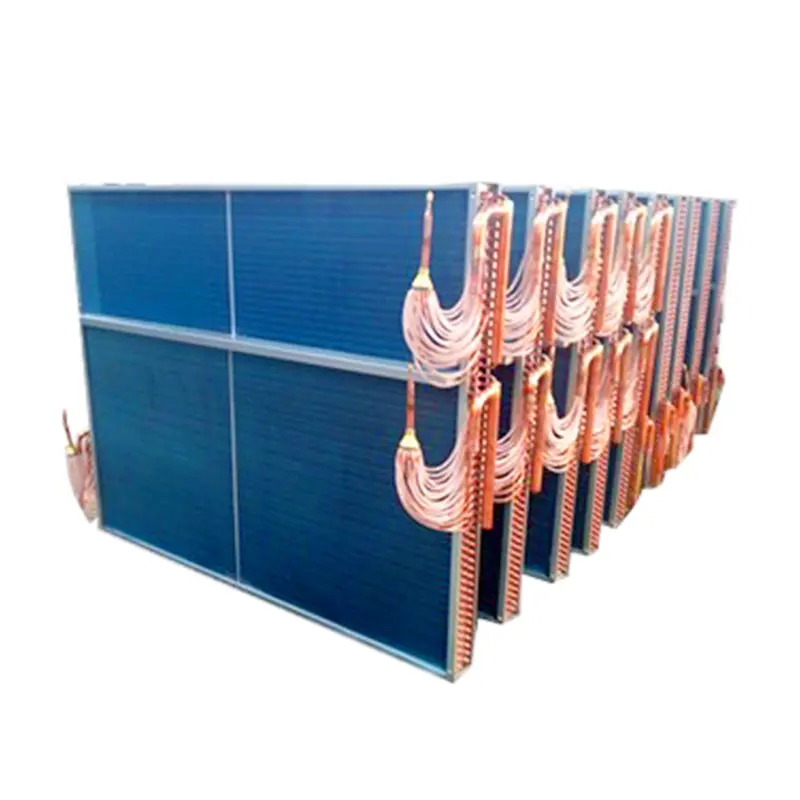

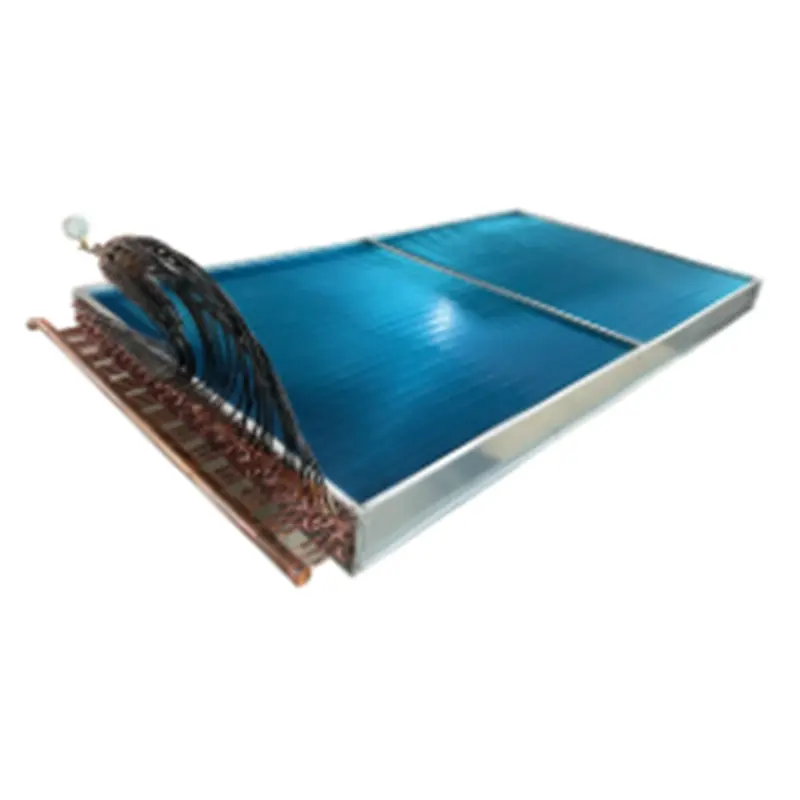

As a leading manufacturer in the industry, we specialize in high-quality Condenser Evaporator heat exchangers tailored for diverse applications. Our factory, Ningbo Senjun New Materials Co., Ltd., ensures that each product meets rigorous standards for performance and reliability. We understand the needs of B2B purchasers like you, looking for wholesale solutions that deliver both efficiency and durability, With years of experience, we pride ourselves on our ability to customize heat exchangers to fit specific requirements, making us a trusted partner for companies worldwide. Our dedicated team works closely with you throughout the process, from sourcing materials to final production, ensuring that every aspect aligns with your expectations. Choosing us means getting support from a team that truly values quality and customer satisfaction. Let’s connect and discuss how our condenser evaporator heat exchangers can optimize your operations and drive your business forward

Must-Know Tips For Condenser Evaporator Heat Exchanger Factory Guarantees Peak Performance Winning in 2025

In the competitive landscape of 2025, maximizing the performance of condenser evaporator heat exchangers is essential for businesses aiming for operational excellence. As a leading manufacturer, Ningbo Senjun New Materials Co., Ltd. understands the critical role these components play in appliances like refrigerators, freezers, and display cabinets. Here are some must-know tips for global buyers to ensure they partner with a factory that guarantees peak performance. First, prioritize suppliers with a proven track record in research and development. With over a decade of experience, Senjun specializes in designing high-efficiency wire tube condensers and copper-aluminum fin heat exchangers. The use of innovative materials and manufacturing techniques ensures not only superior thermal performance but also longevity under different operating conditions. Collaborating with a factory that is committed to ongoing R&D allows you to leverage cutting-edge technology to enhance your products. Additionally, consider factories that emphasize quality control throughout their production processes. At Senjun, each product undergoes rigorous testing to meet international standards, ensuring reliability and efficiency. This commitment to quality not only boosts your product credibility but also supports compliance with global market regulations, giving you a competitive edge. By following these guidelines and partnering with a trusted manufacturer, you can secure advanced heat exchangers that help your business thrive in 2025 and beyond.

Must-Know Tips For Condenser Evaporator Heat Exchanger Factory Guarantees Peak Performance Winning in 2025

| Tip | Details | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| Optimize Airflow | Ensure unobstructed airflow to increase heat transfer efficiency. | Improved performance by up to 15%. | Immediate |

| Regular Maintenance | Schedule regular inspections and cleaning. | Reduced downtime and increased lifespan. | Quarterly |

| Use Advanced Materials | Incorporate corrosion-resistant materials in design. | Enhanced durability and efficiency. | 1-2 years |

| Implement Automation | Utilize automated control systems for monitoring. | Increased operational efficiency by 20%. | 6 months |

| Train Staff | Offer training programs to improve skills. | Better handling of systems and reduced errors. | Ongoing |

Reasons to Choose Condenser Evaporator Heat Exchanger Factory Your Trusted OEM Partner in 2025

J

James Wilson

Exceptional quality! The after-sales service representatives were responsive and educated, making me feel valued.

18 June 2025

N

Noah Wright

The quality of the product is excellent, and the customer service was very professional. I highly recommend them!

15 June 2025

E

Elijah Ramirez

I’m very satisfied with my purchase! The product quality is excellent, and the customer service was very helpful.

17 June 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

J

Jacob Morgan

Very impressed with this product! The quality is superb and the after-sales service was extremely helpful.

01 June 2025

A

Alexander Murphy

A truly wonderful experience! The quality of this product is exceptional, and the service was fast and friendly.

07 June 2025