Wholesale Ultra-Low Temperature Heat Exchanger Manufacturers & Factory

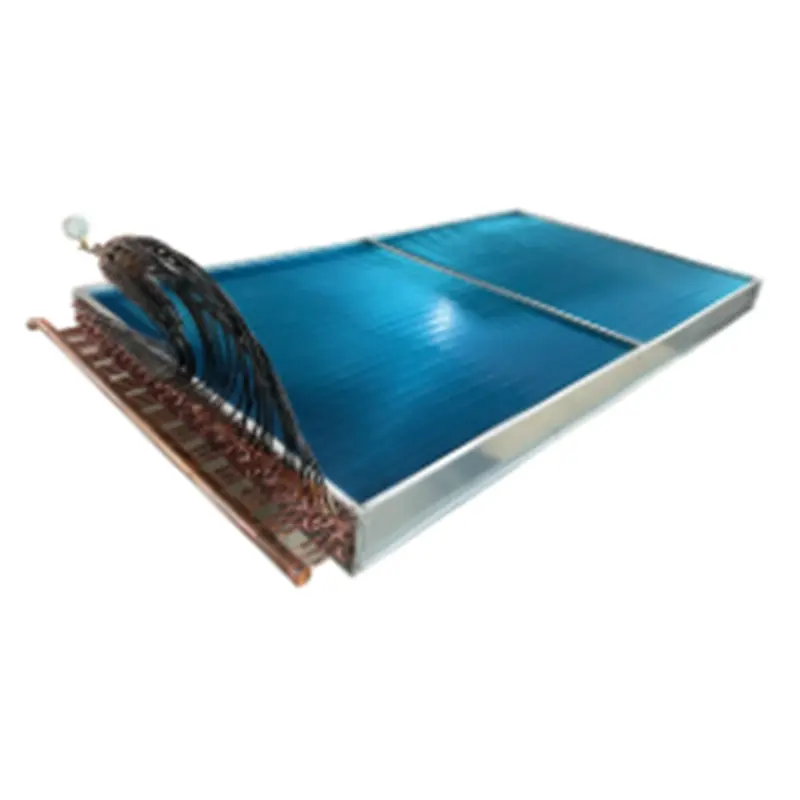

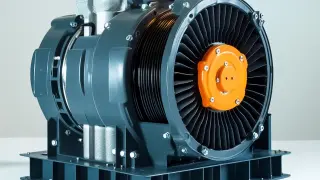

Ningbo Senjun New Materials Co., Ltd. specializes in cutting-edge Ultra-Low Temperature Heat Exchangers, designed to meet the rigorous demands of industries requiring precise thermal management. These heat exchangers operate efficiently in extreme temperature environments, ensuring superior performance and reliability, Engineered with advanced materials and optimized designs, our Ultra-Low Temperature Heat Exchangers provide exceptional thermal conductivity and low-pressure drop, maximizing energy transfer while minimizing operational costs. Ideal for applications in cryogenics, pharmaceuticals, and aerospace, they guarantee your processes remain efficient even under the most challenging conditions, With a commitment to quality and innovation, Ningbo Senjun New Materials Co., Ltd. delivers products that uphold the strictest industry standards. Our experienced team is dedicated to supporting clients in selecting the right solutions tailored to their specific needs. Trust us to enhance your systems with our state-of-the-art heat exchange technology, driving performance and sustainability in your operations

How To Compare Ultra-Low Temperature Heat Exchanger Trusted by Pros Delivers Unmatched Quality

When it comes to selecting an ultra-low temperature heat exchanger, the quality and reliability of the product are paramount. For global procurement professionals, comparing options can be daunting, especially with myriad manufacturers claiming superior performance. At Ningbo Senjun New Materials Co., Ltd., we have established ourselves as a trusted name in the industry since our founding in 2010. Our expertise in wire tube condensers and copper aluminum fin heat exchangers is well-known in applications ranging from refrigerators to display cabinets. One key factor that sets us apart is our unwavering commitment to research and development. Our team continually innovates to enhance the efficiency and durability of our heat exchangers. Trusted by professionals worldwide, our products not only meet but exceed international quality standards. By investing in advanced manufacturing techniques and stringent quality control processes, we ensure that each unit delivers unmatched performance, even in the most demanding conditions. For procurement specialists, evaluating the longevity and energy efficiency of ultra-low temperature heat exchangers is essential. At Senjun, we pride ourselves on providing solutions that not only optimize operational costs but also contribute to sustainable practices. By choosing our heat exchangers, you are partnering with a manufacturer dedicated to quality, innovation, and customer satisfaction, ensuring your investment will yield long-term benefits.

How To Compare Ultra-Low Temperature Heat Exchanger Trusted by Pros Delivers Unmatched Quality

| Model | Cooling Capacity (kW) | Temperature Range (°C) | Efficiency (%) | Weight (kg) | Material |

|---|---|---|---|---|---|

| Model A | 20 | -80 to -40 | 95 | 150 | Stainless Steel |

| Model B | 15 | -75 to -30 | 90 | 120 | Aluminum |

| Model C | 25 | -85 to -50 | 93 | 180 | Copper |

| Model D | 30 | -90 to -60 | 92 | 200 | Stainless Steel |

Why Trust Ultra-Low Temperature Heat Exchanger Products Delivers Unmatched Quality

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

L

Lily Carter

Incredible quality with a flawless design! The after-sales team was very supportive and attentive.

16 May 2025

H

Henry Martinez

Exceptional product quality! The customer service team went above and beyond to assist me.

27 June 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

D

David Lee

Outstanding product! The support team addressed all my concerns with expertise and care.

04 June 2025

O

Olivia Moore

Very pleased with my purchase! The product quality is great, and the customer service was exemplary.

09 June 2025