Top Tube In Tube Heat Exchanger Manufacturers in China - Suppliers Guide

As a leading player in the tube in tube Heat Exchanger market, we pride ourselves on delivering high-quality solutions tailored for various industrial applications. Our products, ideal for energy recovery and heat transfer, are designed to meet the demanding needs of our clients. When you choose us as your wholesale supplier or manufacturer, you’re not just getting superior heat exchangers; you’re partnering with a team that values quality and reliability, Our tube in tube heat exchangers are crafted with precision, ensuring optimal performance and durability. We understand that getting the best solution is crucial for your business, and we’ve got you covered. With years of experience, we’re committed to providing customized services to fit your requirements and enhance your operational efficiency, Let's work together to find the best heat exchanger solution for your needs, ensuring you get the best product at competitive prices. Reach out today, and let’s explore how we can support your business

How To Select Tube In Tube Heat Exchanger Manufacturers From Concept to Delivery in 2025

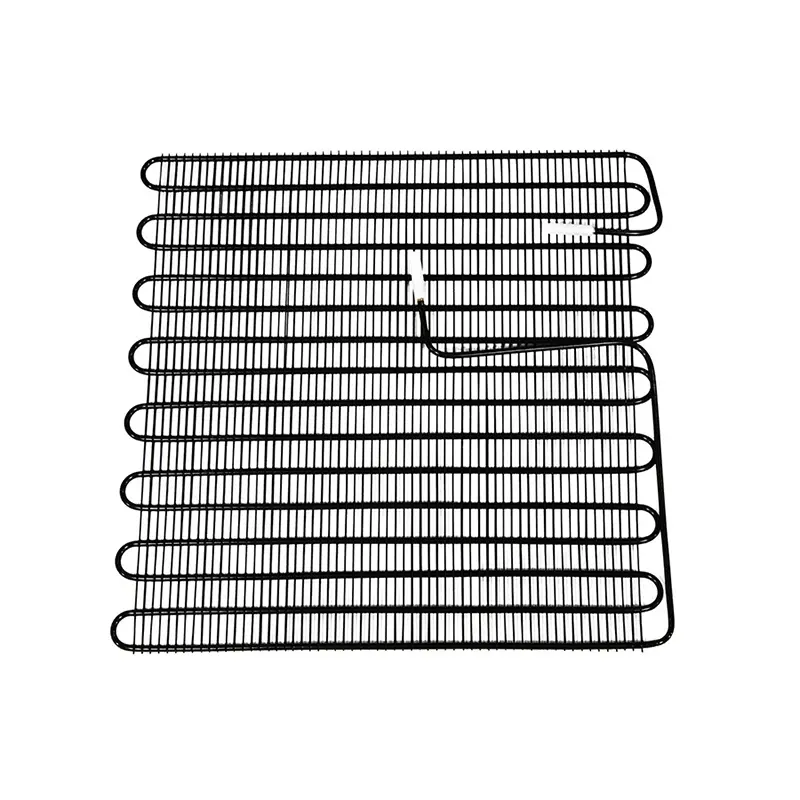

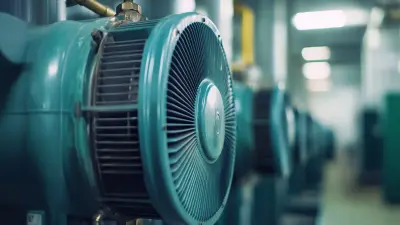

In the rapidly evolving landscape of industrial cooling solutions, selecting the right tube-in-tube heat exchanger manufacturer is crucial for optimizing efficiency and performance. As a global purchaser looking to source these critical components, you should prioritize manufacturers who not only offer innovative designs but also demonstrate a strong commitment to quality and customer satisfaction. One of the key players in this field is Ningbo Senjun New Materials Co., Ltd., which has been at the forefront of heat exchanger technology since its inception in 2010. With a focus on wire tube condensers and copper-aluminum fin heat exchangers, Senjun specializes in supplying essential components for a wide array of applications, including refrigerators, freezers, drinking fountains, and display cabinets. When evaluating potential manufacturers, emphasize their research and development capabilities, as a robust R&D department plays a vital role in staying ahead of industry trends and technological advancements. Companies like Ningbo Senjun not only invest in innovative solutions but also prioritize sustainable materials that comply with international quality standards. This commitment ensures that your heat exchangers will meet operational demands and environmental regulations, leading to increased efficiency and reduced operational costs. Partnering with such manufacturers guarantees a solid pipeline from concept to delivery, giving you peace of mind as you forge ahead in 2025 and beyond.

How To Select Tube In Tube Heat Exchanger Manufacturers From Concept to Delivery in 2025

| Criteria | Description | Importance (1-5) | Current Trends |

|---|---|---|---|

| Quality Certifications | Check for ISO, ASME certifications to ensure quality standards. | 5 | Increasing focus on compliance and certifications. |

| Technical Expertise | Evaluate the engineering capabilities and technical support offered. | 4 | Demand for experienced engineers is rising. |

| Customization Options | Ability to meet specific customer requirements and designs. | 4 | Rising trend in tailored manufacturing solutions. |

| Lead Time | Assess the time from order placement to delivery. | 3 | Importance of quick turnaround times is growing. |

| After-Sales Support | Availability of maintenance and support post-delivery. | 5 | Increasing emphasis on long-term support contracts. |

| Cost Competitiveness | Analyze pricing structures and overall value proposition. | 4 | Balancing cost with quality is a key focus. |

| Industry Experience | Years in business and expertise in the specific market sector. | 5 | Established players are preferred for large projects. |

How-To Guide Tube In Tube Heat Exchanger Manufacturers Outperforms the Competition Is The Best

B

Brian Chen

This product is fantastic! The quality is really high, and their customer service was professional and quite helpful.

23 June 2025

T

Thomas Brown

I can’t praise this product enough! The quality is remarkable, and the after-sales service has been incredibly supportive.

12 June 2025

D

Daniel Clark

High-quality product with an impressive finish. The support team was very knowledgeable and addressed my concerns promptly.

16 June 2025

L

Liam Young

Incredible quality and a helpful customer support team! They made sure my experience was smooth and satisfying.

19 June 2025

E

Ella Simmons

Incredible durability and quality! The customer service representatives were professional and efficient.

04 July 2025

M

Mia Powell

Fantastic durability. The after-sales team was quick to respond and resolved my issues effortlessly.

24 May 2025