Wholesale Tube In Heat Exchanger Suppliers and Factories for Your Needs

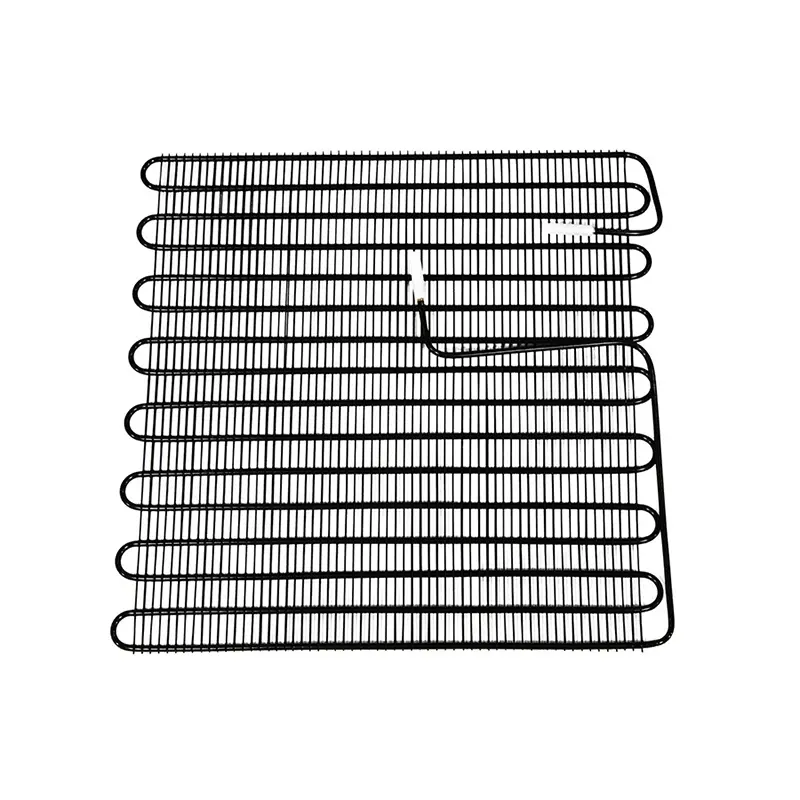

Enhance your thermal management systems with the highly efficient tube in heat exchangers from Ningbo Senjun New Materials Co., Ltd. Designed with cutting-edge technology and superior materials, these tubes ensure optimal Heat Transfer, making them ideal for a variety of industrial applications, Our tubes are engineered to provide exceptional durability and resistance to corrosion, ensuring a long service life even in challenging environments. With customizable sizes and specifications, they cater to diverse operational needs, whether for HVAC systems, petrochemical processes, or renewable energy applications, Ningbo Senjun’s commitment to quality is reflected in our rigorous testing and quality control processes, guaranteeing that every tube meets the highest industry standards. By choosing our heat exchanger tubes, you are investing in efficiency and reliability that boosts your system's overall performance. Trust in our expertise to deliver innovative solutions tailored to your specific requirements and elevate your manufacturing processes to new heights

Expert Tips For Tube In Heat Exchanger Pioneers in the Field From Concept to Delivery

In the fast-evolving world of heat exchanger technology, the role of tube design is crucial. At Ningbo Senjun New Materials Co., Ltd., we've honed our expertise since 2010 in crafting high-performance wire tube condensers and copper-aluminum fin heat exchangers, which are integral to applications such as refrigerators, freezers, and display cabinets. For global purchasers looking to optimize system performance and efficiency, understanding key aspects of tube design and selection is essential. Firstly, it’s imperative to consider the specific thermal requirements of your application. Our team of experts emphasizes customizing the tube design to ensure maximum heat transfer efficiency while minimizing pressure drops. Selecting the right materials is equally important; for instance, our focus on high-quality copper and aluminum not only enhances performance but also ensures longevity and reliability, crucial for competitive market positioning. Moreover, bridging the gap from concept to delivery requires a collaborative approach. We encourage our global partners to engage with us early in the design phase to leverage our extensive R&D capabilities. By doing so, we can tailor solutions that meet both performance and budgetary constraints, enabling a smoother transition from initial concept to finished product. With a commitment to innovation and quality, Ningbo Senjun New Materials Co., Ltd. is your trusted partner in achieving exceptional heat exchanger solutions.

Expert Tips For Tube In Heat Exchanger Pioneers in the Field From Concept to Delivery

| Tip Category | Expert Tip | Expected Outcome | Implementation Timeframe |

|---|---|---|---|

| Material Selection | Choose corrosion-resistant materials for longer life. | Increased durability and reduced maintenance costs. | 1-2 months |

| Design Optimization | Utilize advanced software for thermal and fluid flow analysis. | Improved efficiency and performance. | 2-4 weeks |

| Quality Control | Implement thorough testing procedures after manufacturing. | Minimized risk of failures in the field. | 1 month |

| Maintenance Schedule | Develop a regular maintenance plan to ensure operation. | Extended service life and reliability. | Ongoing |

| Training Programs | Provide staff training on operational best practices. | Enhanced safety and operational efficiency. | 3-6 months |

Effective Ways To Tube In Heat Exchanger From Concept to Delivery Exceeds Industry Benchmarks

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

C

Chloe King

I’m very pleased with this product! The quality is exceptional, and the after-sales service was outstanding.

16 May 2025

S

Samuel Carter

I can’t get over the quality! The customer service team was incredibly professional and responsive.

17 May 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

M

Mia Howard

Unbelievable quality! The customer service team went the extra mile to ensure my satisfaction.

24 May 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025