Wholesale Stainless Steel Tube Coil Heat Exchanger Suppliers - Factories

As a buyer in search of reliable stainless steel tube Coil Heat Exchanger suppliers, you’ll appreciate the exceptional quality we offer. Our products are manufactured in China, where our factories maintain stringent quality controls to ensure durability and efficiency. With a focus on meeting diverse industrial needs, our stainless steel tube coil heat exchangers are designed for optimal performance in various applications, At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on our commitment to customer satisfaction. Our team is dedicated to providing outstanding support and guidance throughout the purchasing process. By choosing us, you’re not just getting a supplier; you’re gaining a partner who understands the market and the importance of dependable supply chains, Whether you’re a small business or a large corporation, our stainless steel tube coil heat exchangers can be tailored to fit your requirements. Trust us for quality and service that stands out in the industry. Let’s build a successful partnership together!

Expert Choice of Stainless Steel Tube Coil Heat Exchanger Suppliers Where Innovation Meets 2025 Products

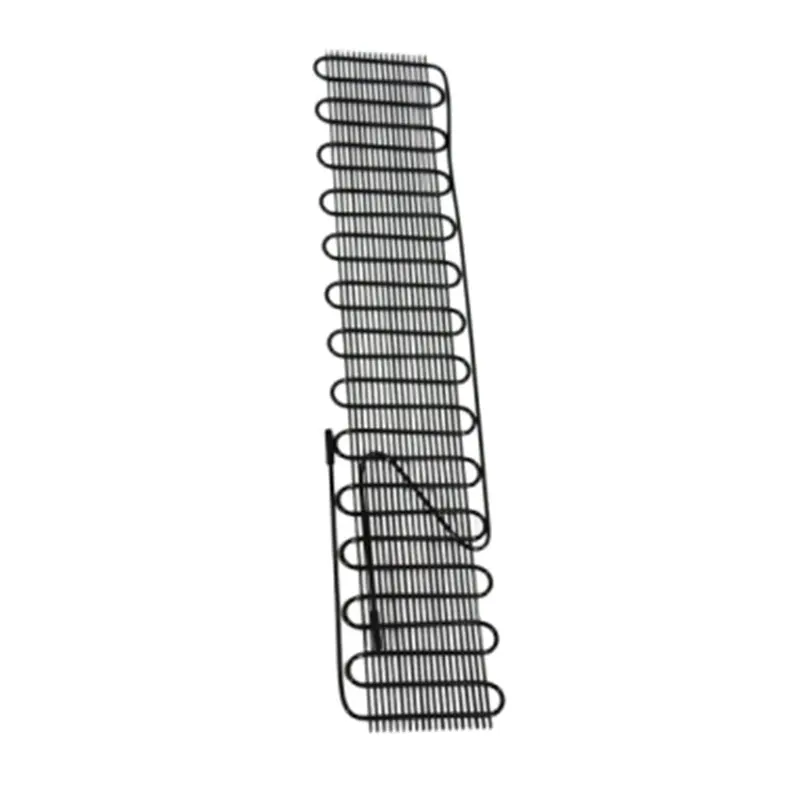

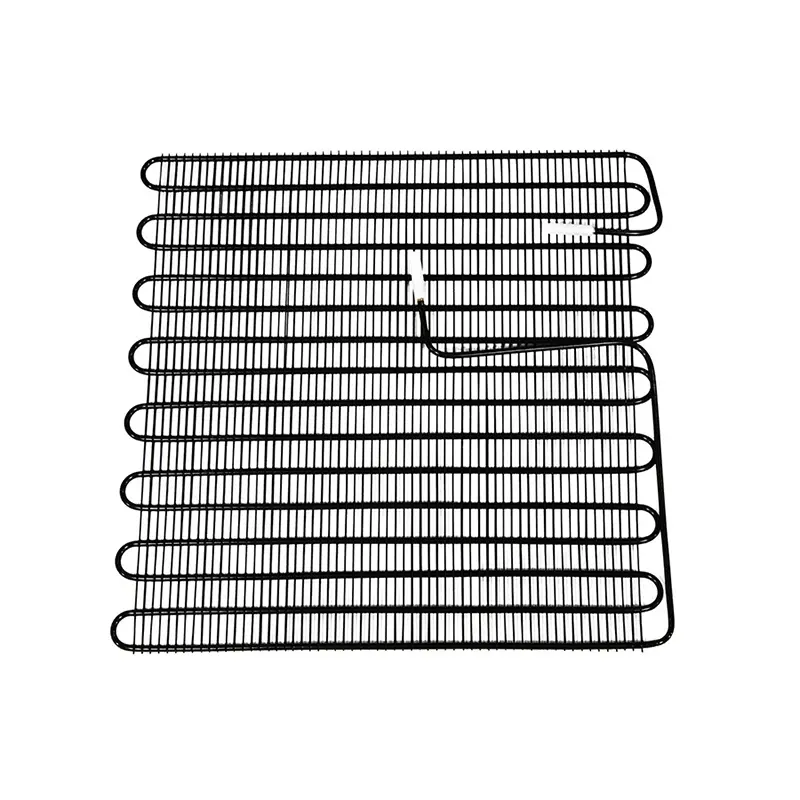

In the rapidly evolving landscape of industrial components, selecting the right supplier for stainless steel tube coil heat exchangers is critical for ensuring efficiency and innovation in your products. At Ningbo Senjun New Materials Co., Ltd., we have dedicated over a decade to the research and development of advanced heat exchange solutions, striving to connect our expertise with the ever-changing demands of global markets. Our extensive range includes high-performance wire tube condensers and copper-aluminum fin heat exchangers, ideal for applications in refrigerators, freezers, drinking fountains, and display cabinets. As we move towards 2025, the focus on sustainable and energy-efficient technologies is more pronounced than ever. With a commitment to innovation, we are continuously enhancing our production processes and product designs to meet these critical needs. Our stainless steel tube coil heat exchangers not only offer excellent thermal efficiency but also boast durability and resistance to corrosion, ensuring they remain operational in even the most challenging environments. Collaborating with Senjun means partnering with a supplier that prioritizes quality, technology, and customer satisfaction, positioning your products for success in a competitive marketplace. For global buyers seeking reliability and cutting-edge solutions, Ningbo Senjun New Materials Co., Ltd. stands out as a trusted partner. Our responsive approach and in-depth knowledge of heat exchanger technology empower you to enhance your product offerings while maintaining cost-effectiveness. Explore the potential of our products today and discover how we can support your business objectives through innovation and quality assurance.

Expert Choice of Stainless Steel Tube Coil Heat Exchanger Suppliers Where Innovation Meets 2025 Products

| Supplier Location | Year Established | Innovative Products | Production Capacity (units/year) | Certifications |

|---|---|---|---|---|

| USA | 2000 | Heat Recovery Systems, Compact Units | 50,000 | ISO 9001, ASME |

| Germany | 1998 | Smart Thermal Solutions, Eco-Friendly Designs | 75,000 | CE, ISO 14001 |

| China | 2010 | Modular Coil Systems, Custom Solutions | 100,000 | ISO 9001, RoHS |

| Canada | 2005 | High Efficiency Heat Exchangers, Hybrid Systems | 30,000 | UL, CSA |

| Japan | 2002 | Advanced Thermal Management, Nanotechnology Applications | 60,000 | ISO 9001, JIS |

The Secret to Stainless Steel Tube Coil Heat Exchanger Suppliers Industry Giant Custom Solutions,

M

Megan Lewis

I’m very happy with my purchase. The product quality is superb, and the after-sales service was incredibly helpful.

10 May 2025

C

Chloe King

I’m very pleased with this product! The quality is exceptional, and the after-sales service was outstanding.

16 May 2025

J

Jack Adams

This is a product of high quality. The after-sales service team was very knowledgeable and assisted me effectively.

26 June 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

R

Ryan Clark

Great product! The quality is unmatched, and the after-sales service was incredibly supportive.

18 May 2025

L

Liam Smith

This product exceeded all my expectations! Outstanding quality and very knowledgeable support team.

12 May 2025