Wholesale Single Tube Heat Exchanger Suppliers & Manufacturers

When searching for reliable Single Tube Heat Exchanger Manufacturers, I understand the importance of quality and efficiency. At our factory, we focus on producing high-performance heat exchangers suitable for various industrial applications. As a supplier offering wholesale options, we cater to businesses seeking durable solutions without compromising on cost, Our commitment to excellence means every Heat Exchanger Is crafted using cutting-edge materials and technology, ensuring long-lasting performance. Working directly with manufacturers like us allows you to streamline your supply chain, maximizing efficiency and minimizing costs. With Ningbo Senjun New Materials Co., Ltd., you can trust that our products meet the highest industry standards, Whether you’re a small factory or a large corporation, we have the capacity to fulfill your needs. Let’s connect to discuss how we can support your business with our top-notch heat exchanger solutions. Quality, reliability, and affordability are just a request away!

How To Compare Single Tube Heat Exchanger Manufacturers Products Application

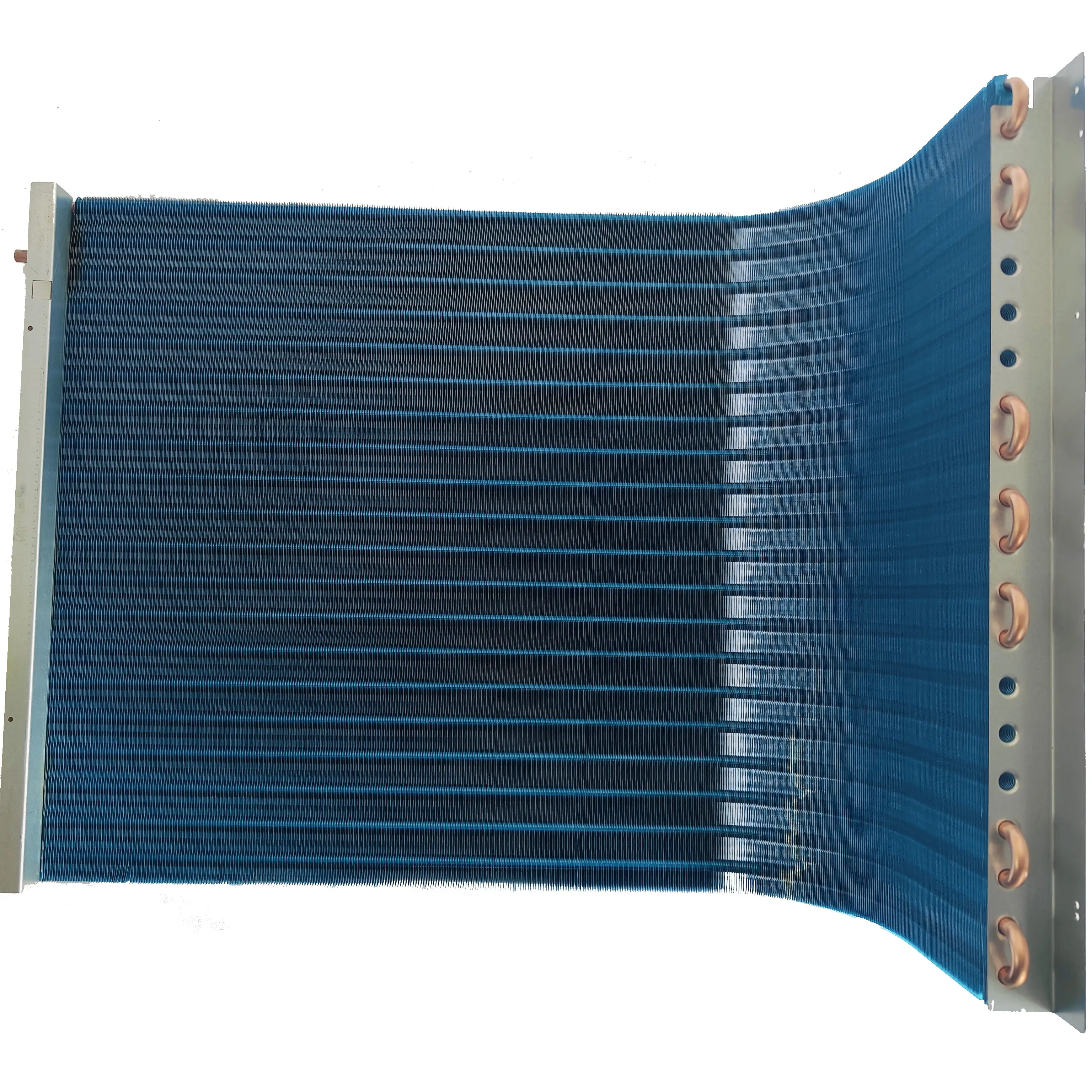

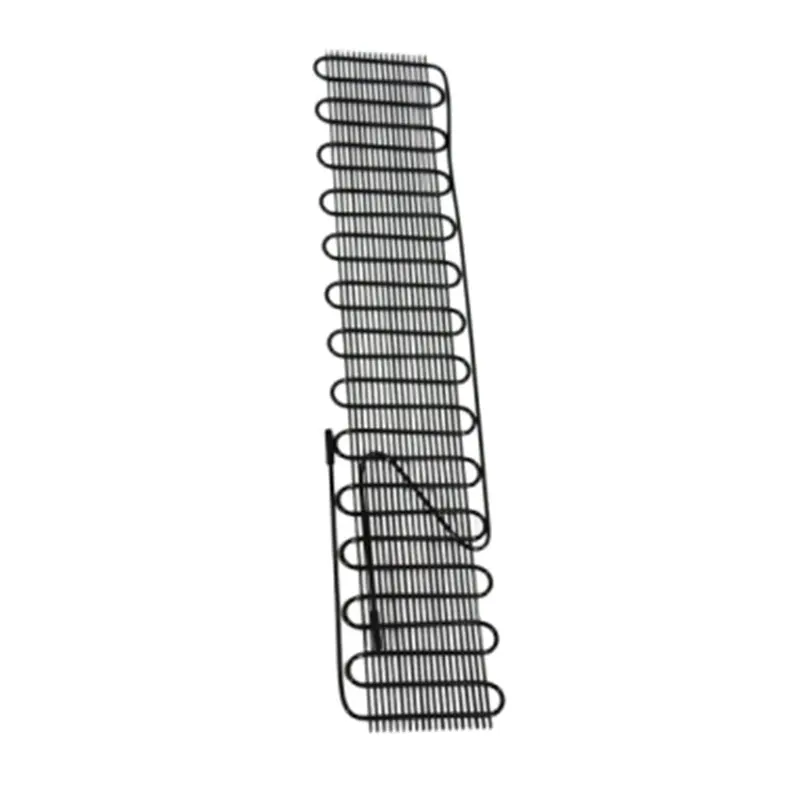

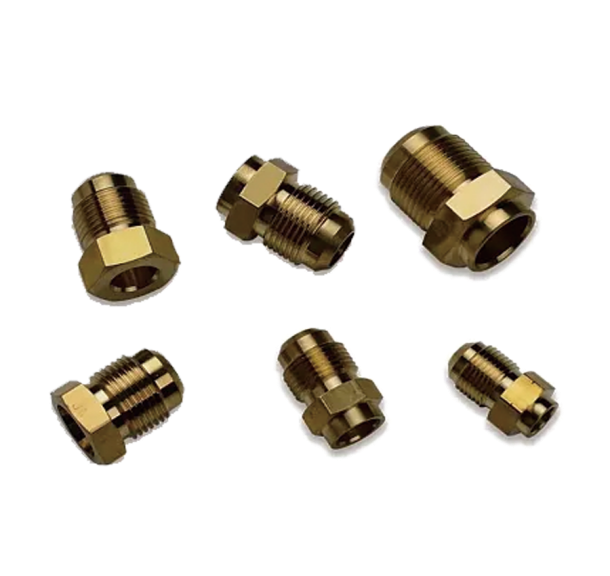

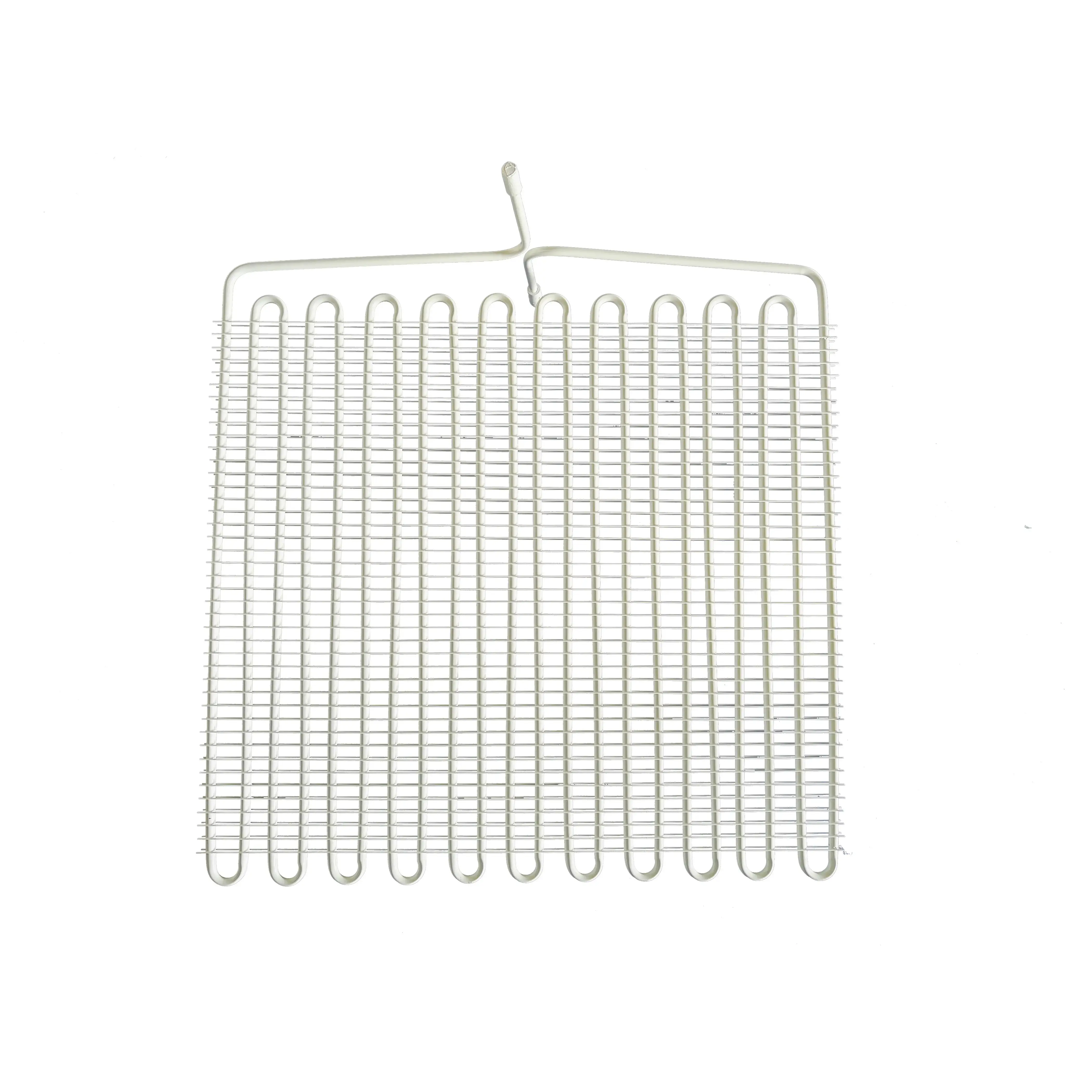

When sourcing single tube heat exchangers, it's essential to understand how to compare different manufacturers effectively, especially in today's global market. One prominent player in this field is Ningbo Senjun New Materials Co., Ltd., established in 2010, known for its innovation in wire tube condensers and copper aluminum fin heat exchangers for a variety of applications including refrigerators, freezers, drinking fountains, and display cabinets. To make an informed decision, consider factors like product quality, manufacturing capabilities, and technological advancements. Evaluate the materials used in their products to ensure durability and efficiency. It’s also vital to review their production processes; a manufacturer with a state-of-the-art facility is likely to deliver superior products. Additionally, compare the range of applications their heat exchangers serve, as versatility can result in better value and adaptability for your specific needs. Finally, don't overlook the importance of customer support and after-sales service. A manufacturer like Ningbo Senjun places emphasis on building relationships with clients, offering tailored solutions that cater to diverse requirements. By conducting thorough research and understanding these key aspects, global buyers can confidently select single tube heat exchanger manufacturers that meet their operational demands.

How To Compare Single Tube Heat Exchanger Manufacturers Products Application

| Manufacturer | Product Model | Material | Max Temperature (°C) | Max Pressure (bar) | Application |

|---|---|---|---|---|---|

| Manufacturer A | Model X1 | Stainless Steel | 200 | 50 | Food Processing |

| Manufacturer B | Model Y2 | Copper | 180 | 30 | Chemical Processing |

| Manufacturer C | Model Z3 | Titanium | 250 | 70 | Marine Applications |

| Manufacturer D | Model W4 | Carbon Steel | 150 | 40 | Heating Systems |

| Manufacturer E | Model V5 | Nickel Alloy | 300 | 80 | Oil & Gas |

Key Methods For Single Tube Heat Exchanger Manufacturers Global Reach Where Service Meets Innovation

E

Emma Allen

I love the quality of this product. The customer service representatives were also extremely helpful and proactive!

10 May 2025

S

Scarlett Baker

I’m thoroughly impressed! The quality is remarkable, and the customer service team provided excellent support.

31 May 2025

E

Elijah Ramirez

I’m very satisfied with my purchase! The product quality is excellent, and the customer service was very helpful.

17 June 2025

G

Gabriel Washington

The product quality is outstanding. The after-sales team was impressive, very knowledgeable, and easy to work with.

06 June 2025

M

Mia Foster

Outstanding quality! The customer service representatives were extremely professional and attentive.

06 July 2025

A

Avery Baker

Superb product quality and excellent customer service! The support staff was very knowledgeable.

05 July 2025