Wholesale Single Tube Heat Exchanger | Reliable Suppliers & Factories

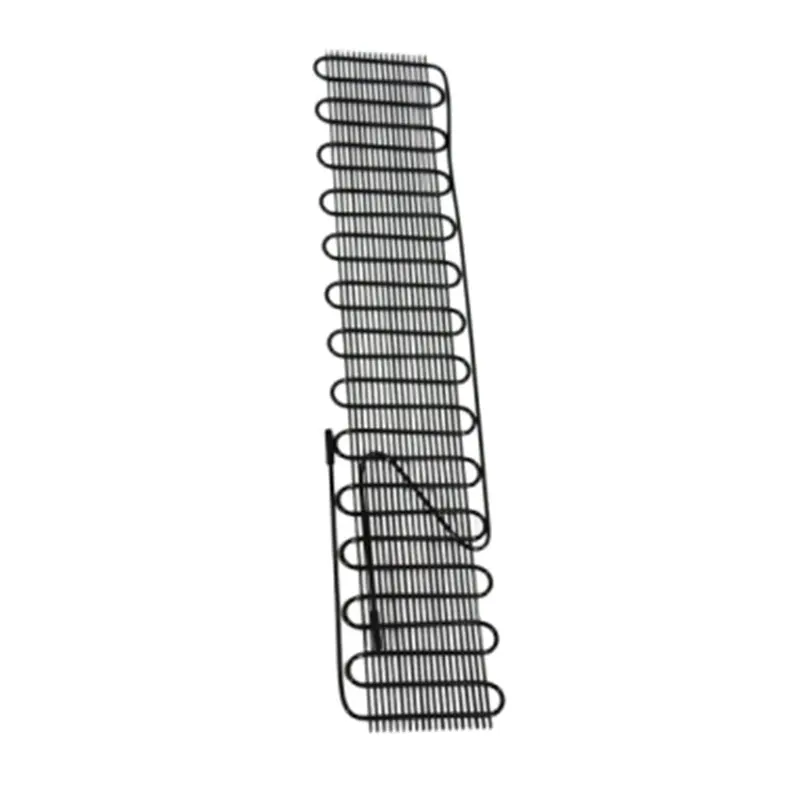

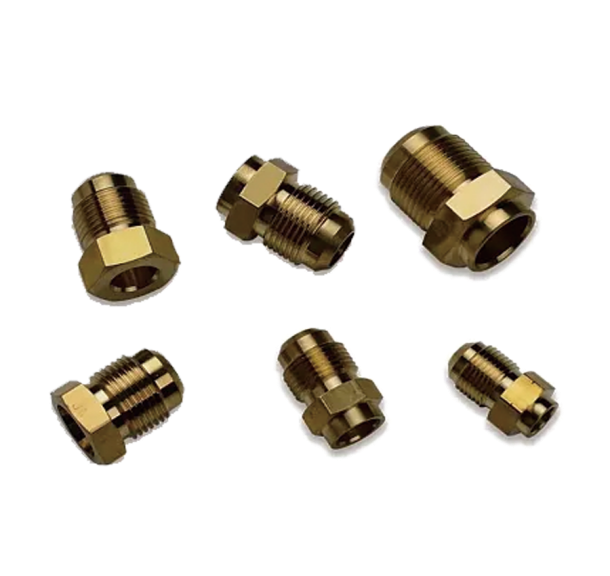

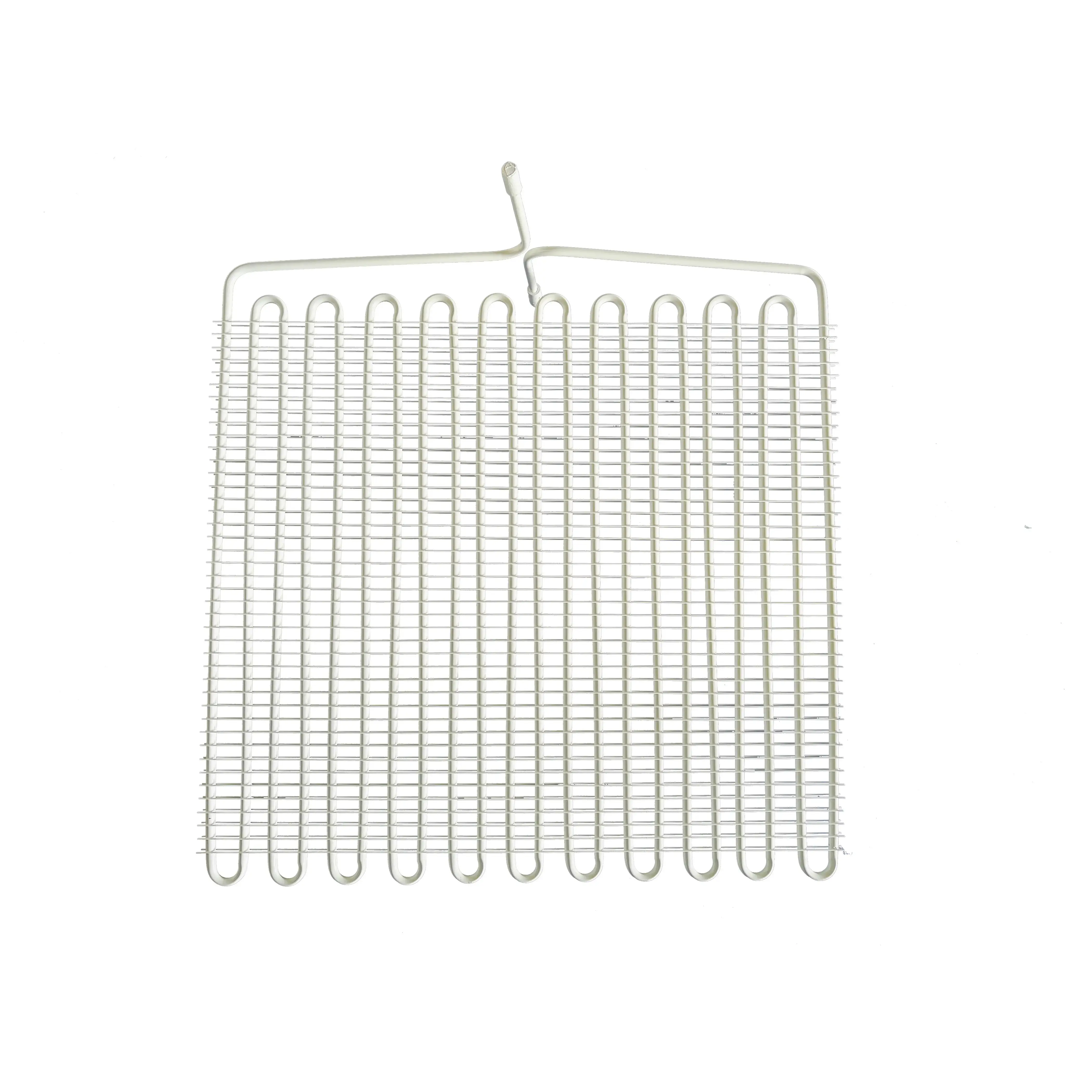

Experience top-tier thermal efficiency with our Single Tube Heat Exchanger, expertly crafted by Ningbo Senjun New Materials Co., Ltd. Designed for diverse industrial applications, this heat exchanger features a streamlined construction that maximizes surface area, ensuring optimal heat transfer while maintaining compact dimensions, Manufactured using high-quality materials, our Single Tube Heat Exchanger offers outstanding durability and resistance to corrosion, making it an ideal choice for challenging environments. It is engineered to handle varying fluid types and temperatures, providing versatility across many industries, including chemical processing, HVAC, and food production, Efficiency is at the core of our design, allowing for reduced maintenance costs and enhanced operational reliability. Trust in Ningbo Senjun New Materials Co., Ltd. for innovative solutions that stand the test of time. Our commitment to quality and performance ensures that your processes run smoothly and effectively, making this heat exchanger a valuable addition to your system. Upgrade your thermal management strategy with our advanced technology today!

Key Steps to Choosing Single Tube Heat Exchanger Sets the Industry Standard Products

Choosing the right single tube heat exchanger is crucial for businesses aiming to improve efficiency and set industry standards. At Ningbo Senjun New Materials Co., Ltd., we understand that the decision-making process for global purchasers can be daunting. Since our establishment in 2010, we have specialized in the research, development, and production of advanced wire tube condensers and copper aluminum fin heat exchangers tailored for a variety of applications, including refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to quality and innovation ensures that our products not only meet but exceed industry requirements. When selecting a heat exchanger, consider key factors such as material durability, thermal efficiency, and compatibility with existing systems. Our heat exchangers are engineered with high-quality materials that withstand harsh conditions while ensuring optimal thermal performance. Furthermore, our extensive range of products is designed to fit various refrigeration and cooling needs, making it easier for procurement teams to find the perfect match for their operational requirements. By prioritizing these aspects, buyers can confidently choose heat exchangers that will enhance productivity and drive down energy costs. In a competitive market, working with a reliable supplier like Ningbo Senjun is essential. Our experience and expertise in producing industry-standard heat exchangers empower global purchasers to achieve unparalleled performance in their cooling systems. We invite you to explore our innovative solutions and join us in setting new benchmarks within the industry. Partner with us for advanced heat exchangers that promise quality, efficiency, and long-term value.

Key Steps to Choosing Single Tube Heat Exchanger Sets the Industry Standard Products

| Parameter | Value | Notes |

|---|---|---|

| Fluid Type | Water | Commonly used in cooling applications |

| Max Operating Temperature | 150°C | Temperature limit of materials |

| Heat Transfer Area | 50 m² | Effective area for heat exchange |

| Material | Stainless Steel | Corrosion resistant and durable |

| Flow Type | Counterflow | Maximizes heat exchange efficiency |

| Pressure Drop | 5 bar | Acceptable pressure drop for the system |

| Weight | 300 kg | Consideration for installation |

| Maintenance Frequency | Annually | Recommended to ensure performance |

Reasons to Choose Single Tube Heat Exchanger Industry Giant Stands Out

M

Michael Thompson

I’m genuinely impressed with the quality of this product. The durability and design are exceptional, and the customer service team has been incredibly responsive.

26 June 2025

O

Olivia Davis

The craftsmanship of this product is top-tier. I was pleasantly surprised by the professionalism of the customer service team.

04 July 2025

R

Ryan Turner

I’m very satisfied! The item quality is great, and the after-sales service was attentive and professional.

23 June 2025

E

Emma Allen

I love the quality of this product. The customer service representatives were also extremely helpful and proactive!

10 May 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025