Wholesale Shell and Tube Condenser | Tube-in-Tube Manufacturers & Suppliers

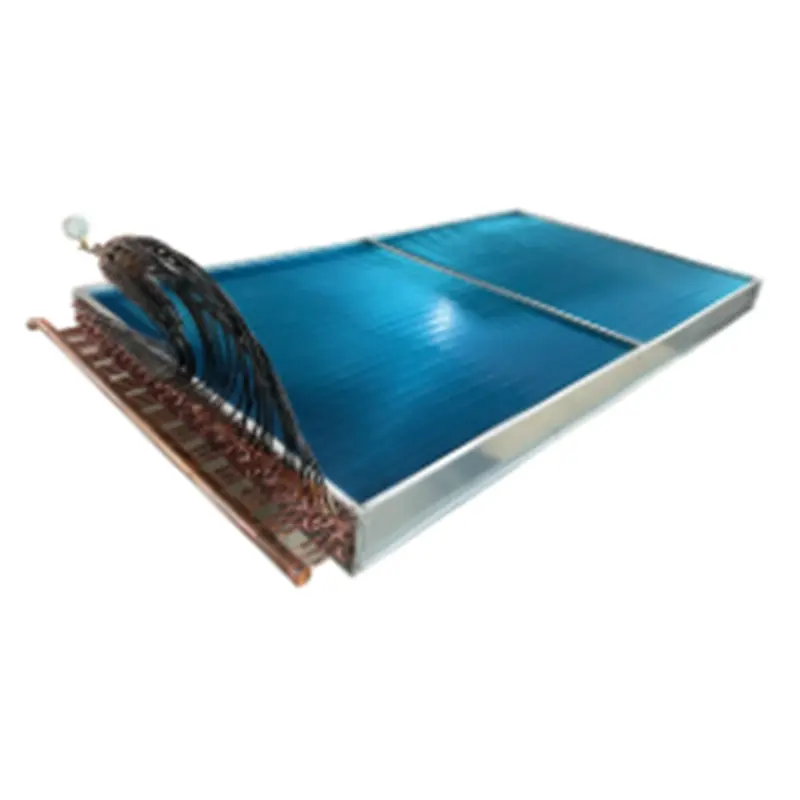

Ningbo Senjun New Materials Co., Ltd. proudly presents its advanced Shell and Tube Condenser, featuring a highly efficient tube-in-tube design. This innovative condenser optimizes heat exchange while minimizing energy consumption, making it an ideal choice for various industrial applications, The shell and tube configuration allows for superior thermal performance, with specially designed tubes that enhance flow dynamics and facilitate easier maintenance. Engineered for durability, our condensers are constructed from high-quality materials that resist corrosion and withstand harsh operating conditions, With a commitment to quality and performance, our condensers ensure reliable operation across diverse environments, from chemical processing to refrigeration systems. The efficient heat transfer capabilities contribute to enhanced energy savings, making it a cost-effective solution in the long run, Explore the cutting-edge technology of our tube-in-tube condenser and elevate your operational efficiency with Ningbo Senjun New Materials Co., Ltd.'s expertise and innovation. Experience unmatched reliability and superior performance in your thermal management systems today

Advantages Explained Shell And Tube Condensertube-In-Tube Condenser Pioneers in the Field Where Service Meets Innovation

In the rapidly evolving landscape of refrigeration technologies, Ningbo Senjun New Materials Co., Ltd. stands at the forefront with our innovative shell and tube condensers. Established in 2010, we have dedicated ourselves to the research, development, and production of high-quality wire tube condensers and copper-aluminum fin heat exchangers. Our products are extensively utilized in refrigerators, freezers, drinking fountains, and display cabinets, meeting diverse global market needs. What sets our shell and tube condensers apart is their superior efficiency and reliability. The tube-in-tube design significantly enhances the heat exchange process, allowing for optimal thermal performance while minimizing energy consumption. This innovation not only reduces operational costs for our clients but also promotes sustainability in their businesses. As pioneers in this field, we emphasize service excellence alongside technological advancement, ensuring that our global partners receive personalized support and tailored solutions to their specific requirements. Ningbo Senjun remains committed to continuous improvement and customer satisfaction. We invite global buyers to explore our extensive range of products that embody cutting-edge engineering and exceptional performance. Let us partner with you to revolutionize your cooling systems and drive business success through innovative solutions.

Advantages Explained Shell And Tube Condenser Tube-In-Tube Condenser Pioneers in the Field Where Service Meets Innovation

| Advantage | Description | Applications | Efficiency | Maintenance |

|---|---|---|---|---|

| Compact Design | Takes up less space compared to other condenser types. | Used in space-constrained applications. | High thermal efficiency due to compact structure. | Requires less frequent maintenance. |

| Versatile Configuration | Can be designed for various fluid combinations. | Applicable in chemical processing and HVAC systems. | Versatile efficiency across different applications. | Flexible maintenance options depending on configuration. |

| High Heat Transfer | Offers improved heat transfer surfaces. | Ideal for power generation and refrigeration. | Enhances overall system efficiency. | Easier to clean and service due to access points. |

| Durability | Robust construction for long-lasting performance. | Suitable for harsh operating environments. | Consistent performance over time. | Durable materials require less frequent replacement. |

How To Select Shell And Tube Condensertube-In-Tube Condenser Supplier Leads the Global Market

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

S

Sebastian Jenkins

Excellent product! The customer support staff were highly professional and very helpful.

09 June 2025

E

Ella Simmons

Incredible durability and quality! The customer service representatives were professional and efficient.

04 July 2025

N

Noah Gonzalez

Very happy with my purchase! The product is top quality, and the customer support was very helpful.

22 May 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

H

Henry Martinez

Exceptional product quality! The customer service team went above and beyond to assist me.

27 June 2025