Top Shell and Coil Evaporator Manufacturers in China - Leading Factories

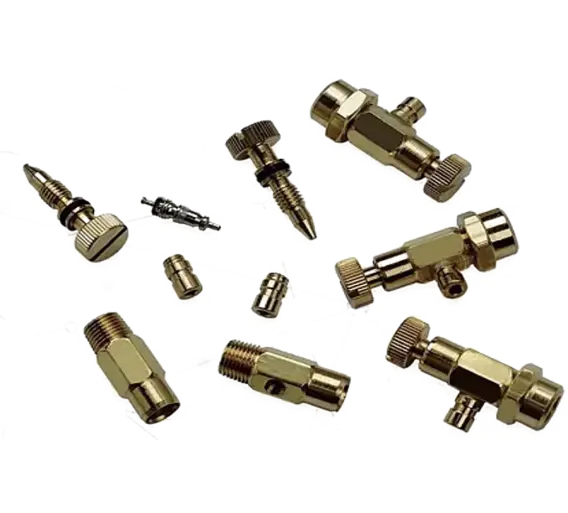

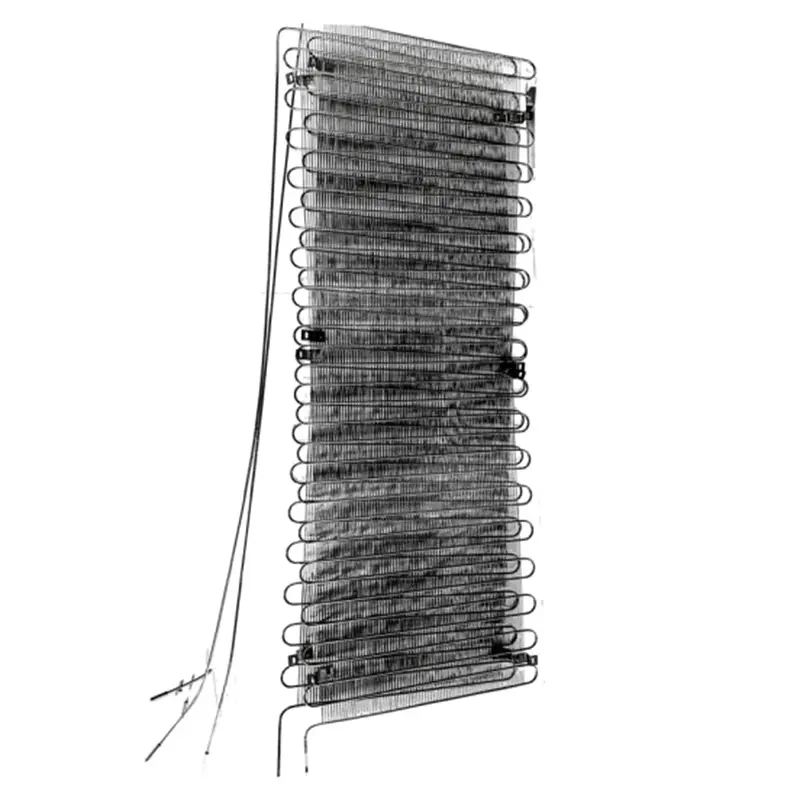

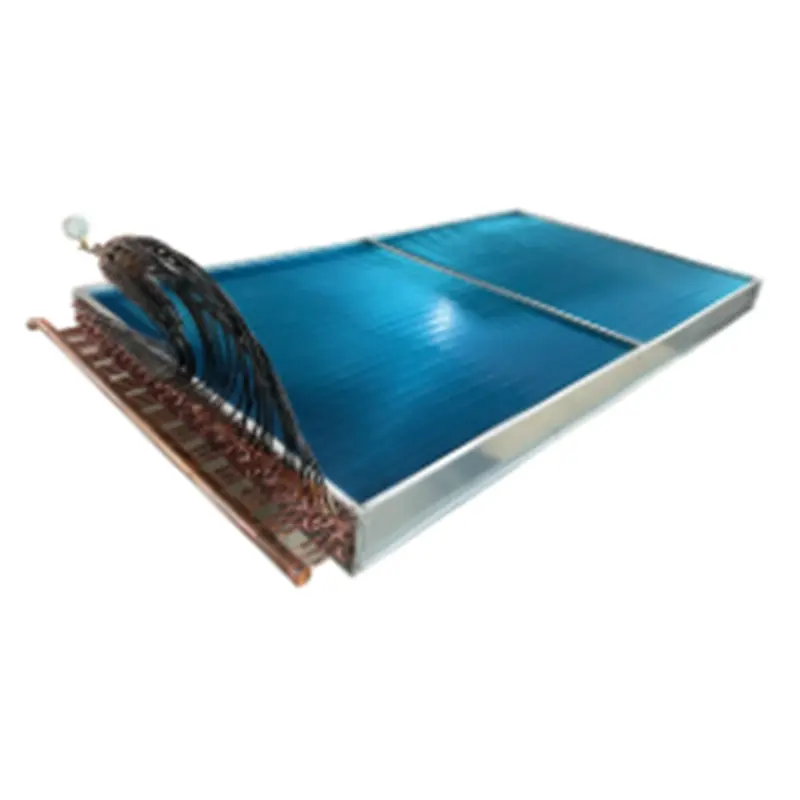

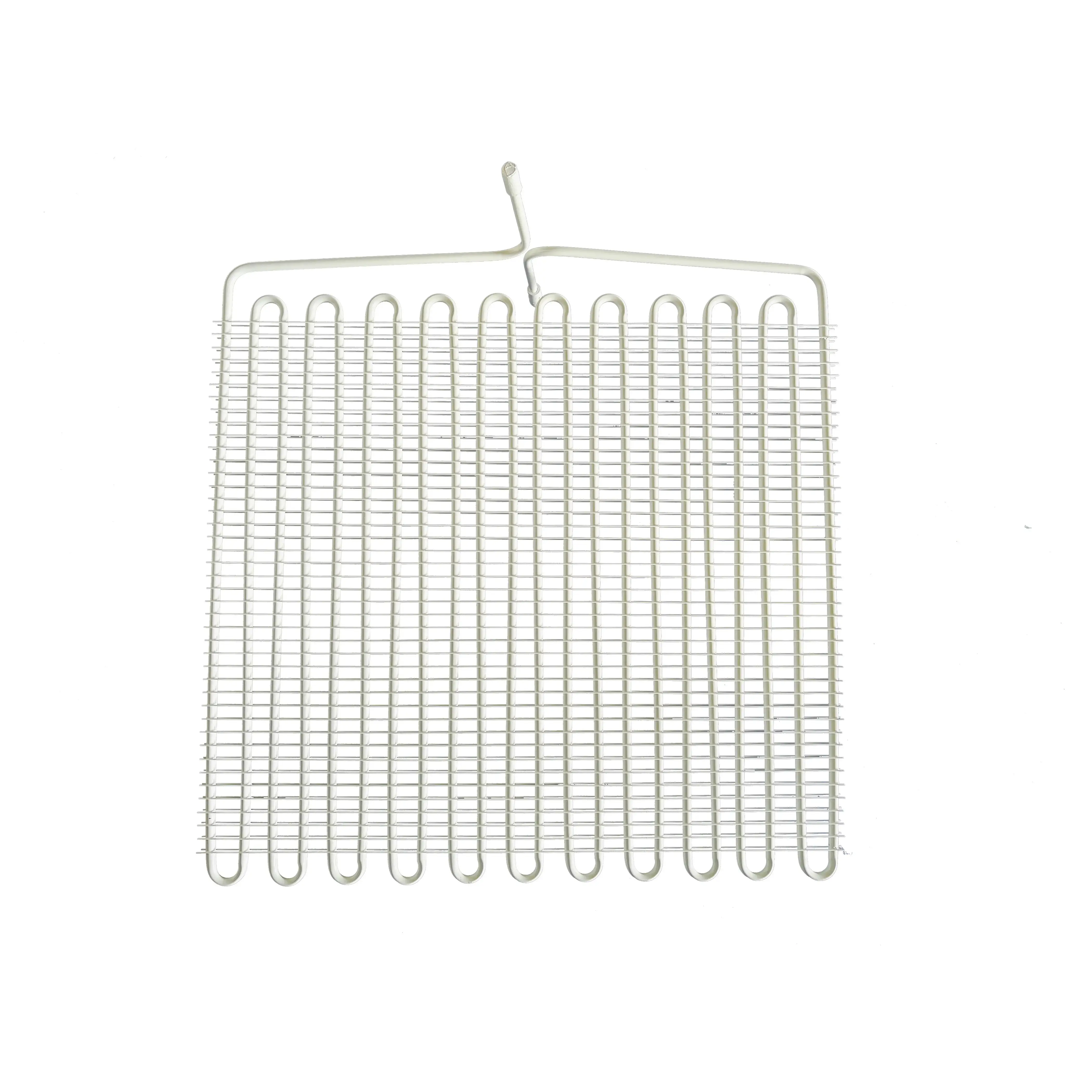

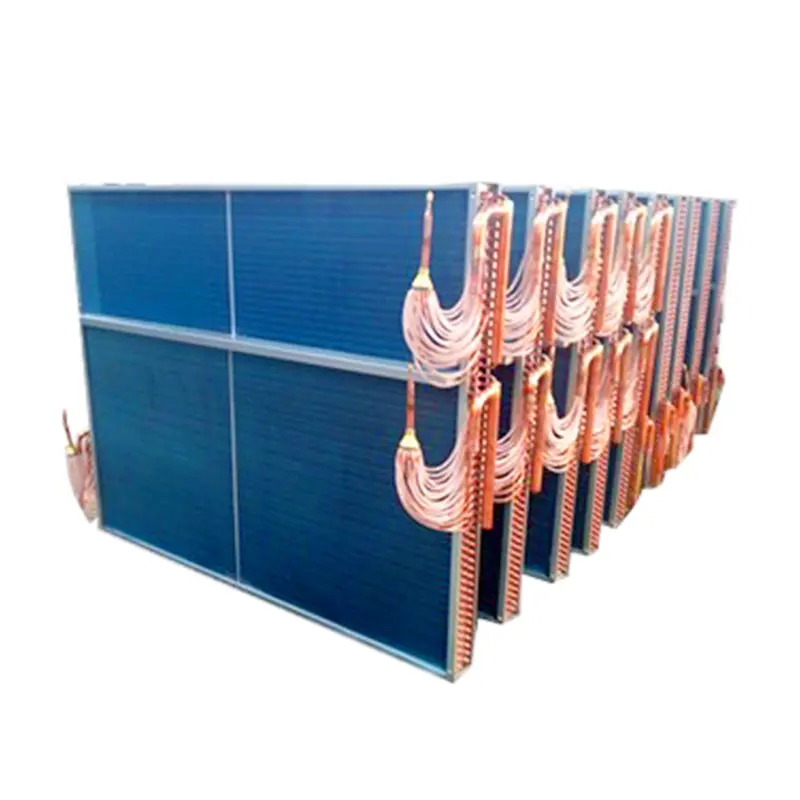

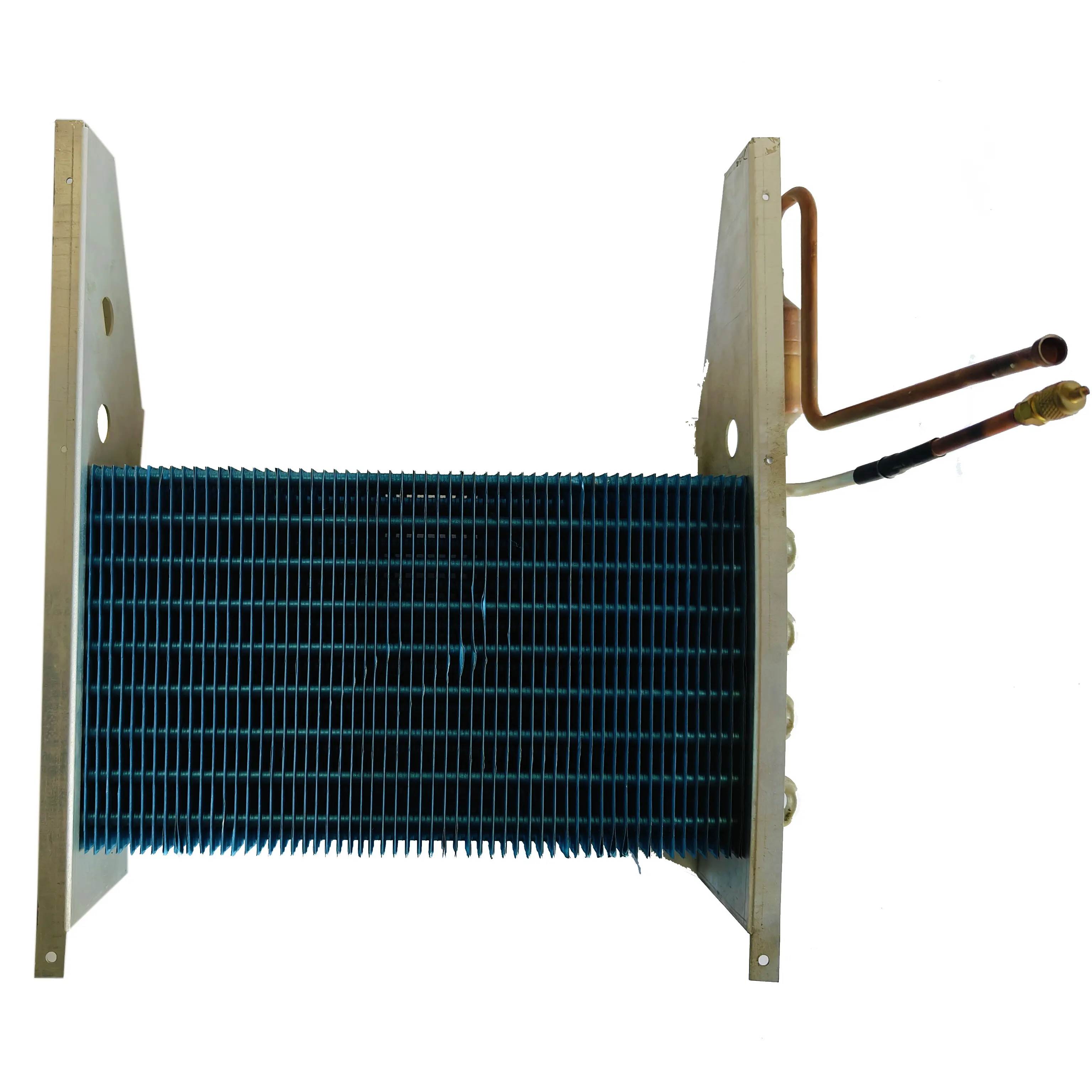

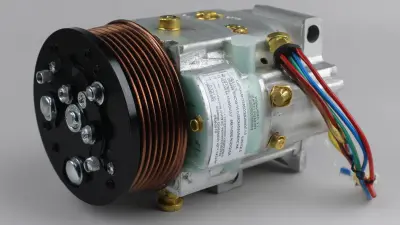

Ningbo Senjun New Materials Co., Ltd. proudly presents its advanced Shell and Coil Evaporator, a cutting-edge solution designed for optimal efficiency and reliability in various industrial applications. Constructed with high-quality materials, this evaporator features a unique shell and coil design that maximizes heat exchange, making it an ideal choice for refrigeration and HVAC systems, Engineered for versatility, the Shell and Coil Evaporator effectively handles diverse working conditions, ensuring consistent performance. Its compact design allows for easy installation and space-saving in facilities, while its robust construction enhances durability and minimizes maintenance needs, This innovative evaporator is tailored to meet the demands of modern industries, providing energy-efficient solutions that contribute to lower operational costs. With Ningbo Senjun’s commitment to quality and excellence, clients can trust that they are investing in a reliable product that supports sustainable practices and optimizes system performance. Discover the benefits of our Shell and Coil Evaporator and elevate your operational efficiency today

The Secret to Shell And Coil Evaporator Service Factory

When it comes to optimizing the performance and longevity of shell and coil evaporators, understanding the nuances of their service and maintenance is crucial. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on our extensive expertise in the manufacturing of top-tier wire tube condensers and copper-aluminum fin heat exchangers. Since our founding in 2010, we have dedicated ourselves to pushing the boundaries of innovation while ensuring the highest quality for applications in refrigerators, freezers, drinking fountains, and display cabinets. The secret to effective shell and coil evaporator service lies in rigorous maintenance protocols that enhance reliability and efficiency. Regular inspections and timely servicing can prevent costly downtimes and extend the lifespan of your equipment. Our advanced manufacturing processes not only ensure the durability of our products but also facilitate ease of maintenance—allowing global buyers to benefit from reduced operational risks. At Senjun, we understand the unique needs of our international clients. Our commitment to quality and service excellence makes us the ideal partner for those looking to procure reliable and cutting-edge evaporator solutions. By choosing Senjun, you are not just acquiring products; you are ensuring a continuous, efficient operation that meets the demands of your market. Explore our offerings and discover how we can support your business in achieving optimal performance.

The Secret to Shell And Coil Evaporator Service Factory

| Service Type | Description | Frequency | Estimated Cost ($) |

|---|---|---|---|

| Regular Maintenance | Inspection and cleaning of evaporator coils to ensure efficient operation. | Every 6 Months | 150 |

| Leak Testing | Testing for refrigerant leaks to prevent efficiency loss. | Once a Year | 200 |

| Full System Check | Comprehensive examination of the entire refrigeration system. | Every 2 Years | 350 |

| Replacement of Coils | Replacement of damaged or worn evaporator coils. | As Needed | 800 |

| Refrigerant Recharge | Adding refrigerant to system to ensure optimal performance. | As Needed | 250 |

The Clear Choice of Shell And Coil Evaporator Where Service Meets Innovation Dominates

E

Elena Johnson

Absolutely satisfied with my purchase. The product is built to last, and the customer service staff are very courteous and efficient.

06 July 2025

A

Ava Diaz

I can highly recommend this product! The quality is great, and their customer service is professional and helpful.

09 June 2025

L

Liam Bennett

I’ve had nothing but a positive experience! The product is of excellent quality and service team is very helpful.

15 June 2025

A

Ava Nguyen

Amazing quality and superb service! The support team was incredibly knowledgeable.

15 May 2025

N

Noah Nelson

Incredible quality! The customer service team was eager to assist and very professional.

06 July 2025

E

Emma Hill

Thrilled with this product! Its quality is remarkable, and the support team was very helpful.

02 July 2025