Wholesale Plate Heat Exchanger Condenser Factory - Quality Manufacturers

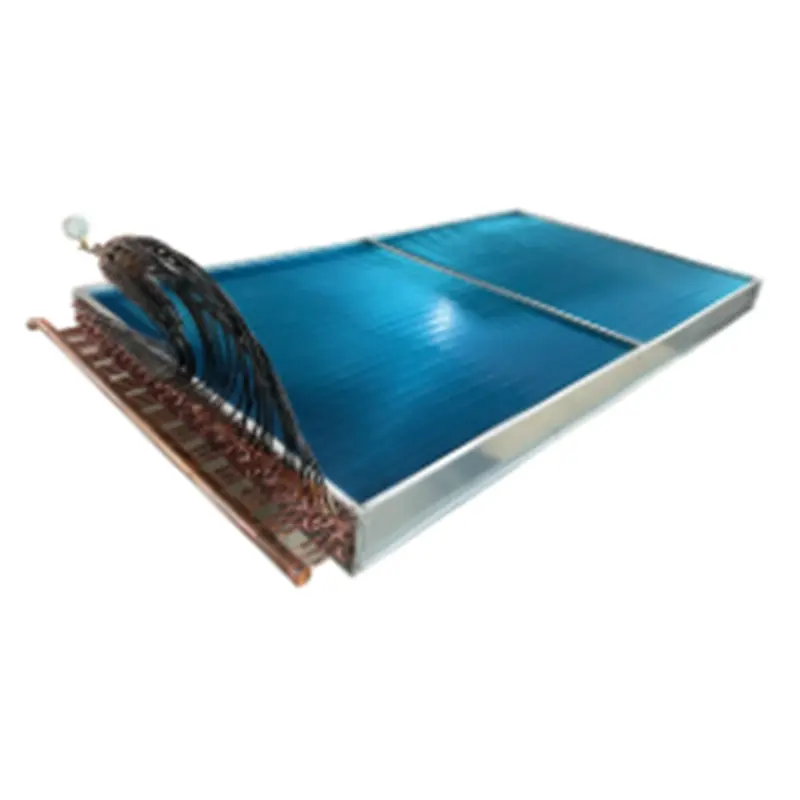

At our Plate Heat Exchanger Condenser Factory in China, we specialize in top-quality heat exchangers that meet diverse industrial needs. I understand the importance of reliability and efficiency in your operations, and that's why our products are designed with the latest technology and superior materials, As a leading supplier, we pride ourselves on our ability to customize solutions that align with the specific requirements of your projects. Our team works closely with clients, ensuring that we deliver not just products, but also exceptional service, When you partner with us, you're choosing a manufacturer committed to quality and innovation. Whether you’re looking for standard models or tailored designs, our experienced staff is ready to assist you. Trust Ningbo Senjun New Materials Co., Ltd. to be your go-to source for plate heat exchangers—where quality and performance go hand in hand!

Tips & Tricks for Plate Heat Exchanger Condenser Factory Application Dominates

In the ever-evolving landscape of industrial equipment, plate heat exchangers have emerged as vital components in optimizing energy efficiency and thermal management. At Ningbo Senjun New Materials Co., Ltd., we have dedicated ourselves to advancing the art of cooling technologies since our inception in 2010. Our expertise in producing wire tube condensers and copper aluminum fin heat exchangers ensures that our clients, spanning refrigerators, freezers, drinking fountains, and display cabinets, receive products that excel in both performance and reliability. When considering the application of plate heat exchangers in factories, several key tips can guide purchasing decisions. Firstly, focus on the specific thermal requirements of your operation; understanding the heat transfer rates needed will lead to selecting the appropriate model. Additionally, evaluate the compatibility of materials with the fluids involved, as corrosion resistance can greatly impact longevity. Maintenance considerations should also play a crucial role in your choice; opting for easy-to-clean designs can reduce downtime and operational costs, enhancing overall efficiency. At Ningbo Senjun, we pride ourselves on our commitment to innovation and quality. By partnering with us, global buyers can access cutting-edge heat exchanger solutions tailored to their unique applications. With our extensive experience in the industry, we are well-equipped to provide valuable insights and support, ensuring that our clients not only meet but exceed their operational goals.

Tips & Tricks for Plate Heat Exchanger Condenser Factory Application Dominates

| Application Area | Optimal Temperature (°C) | Pressure Drop (bar) | Efficiency (%) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Industrial Refrigeration | -10 to 5 | 0.5 | 85 | 6 |

| Food Processing | 60 to 80 | 0.3 | 90 | 12 |

| Chemical Processing | 30 to 70 | 0.4 | 95 | 8 |

| HVAC Systems | 10 to 30 | 0.2 | 88 | 9 |

| Power Generation | 70 to 90 | 0.6 | 92 | 7 |

Avoiding Pitfalls Plate Heat Exchanger Condenser Factory Service Custom Solutions,

M

Megan Lewis

I’m very happy with my purchase. The product quality is superb, and the after-sales service was incredibly helpful.

10 May 2025

L

Liam Young

Incredible quality and a helpful customer support team! They made sure my experience was smooth and satisfying.

19 June 2025

J

Jack Adams

This is a product of high quality. The after-sales service team was very knowledgeable and assisted me effectively.

26 June 2025

O

Olivia White

Very high quality. The support team was quick to assist and very knowledgeable.

26 May 2025

S

Sophia Young

Excellence in both product and service! The after-sales team provided the assistance I needed.

20 May 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025