Heat Exchanger in Heat Pump: Top Manufacturers & Factories in China

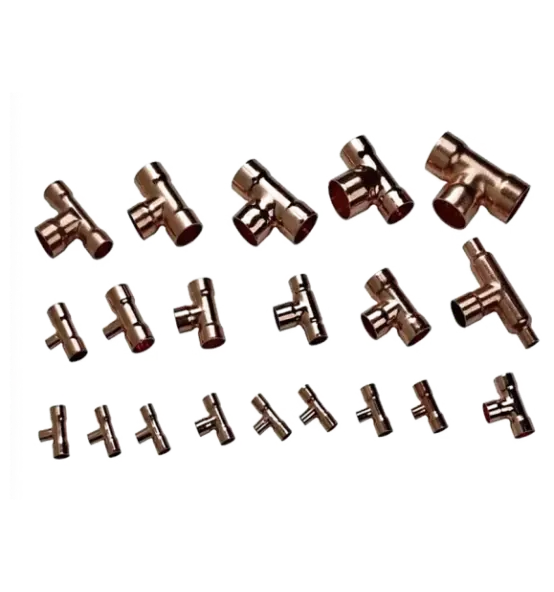

Ningbo Senjun New Materials Co., Ltd. presents cutting-edge heat exchangers designed specifically for heat pump applications. These innovative products enhance energy efficiency, enabling users to optimize their heating and Cooling Systems effectively. Manufactured with high-quality materials, our heat exchangers deliver superior thermal performance and durability, ensuring long-lasting reliability under varying operational conditions, Engineered to facilitate maximum heat transfer, these exchangers minimize energy consumption while maximizing performance. The compact design allows for easy integration into existing systems, making them suitable for residential, commercial, and industrial uses, With a focus on sustainability, our heat exchangers contribute to reducing environmental impact by improving energy efficiency in heating and cooling processes. Clients can expect tailored solutions that meet their specific requirements, backed by exceptional customer support. Choose Ningbo Senjun New Materials Co., Ltd. for innovative heat exchangers that deliver exceptional performance and efficiency in any heat pump application

Exploring Heat Exchanger In Heat Pump Supplies the World’s Top Brands Factory

In the rapidly evolving world of HVAC and refrigeration technology, heat exchangers play a pivotal role in enhancing energy efficiency and performance. At Ningbo Senjun New Materials Co., Ltd., we have dedicated over a decade to advancing the design and production of wire tube condensers and copper-aluminum fin heat exchangers. Our commitment to innovation has allowed us to serve some of the world’s top brands in various applications, including refrigerators, freezers, drinking fountains, and display cabinets. As global demand for energy-efficient appliances continues to rise, our heat exchangers stand out for their superior thermal performance and durability. Our state-of-the-art manufacturing processes ensure that each product meets the highest standards of quality, providing reliable solutions that meet the specific needs of international buyers. By utilizing advanced materials and cutting-edge technology, we enable our partners to achieve significant energy savings, reduce operational costs, and enhance consumer satisfaction. Whether you are looking for a trusted supplier for your next project or seeking to upgrade your current product offerings, Ningbo Senjun New Materials Co., Ltd. is your go-to source for premium heat exchangers. Our dedication to research and development, combined with our responsive customer service, positions us as a preferred partner in meeting the ever-evolving requirements of the global marketplace. Together, let us drive the future of energy-efficient solutions forward.

Exploring Heat Exchanger In Heat Pump Supplies the World’s Top Brands Factory

| Feature | Value |

|---|---|

| Type of Heat Exchanger | Air-to-Air |

| Material | Copper and Aluminum |

| Efficiency Rating | Up to 95% |

| Operating Temperature Range | -20°C to 60°C |

| Pressure Drop | |

| Application | Residential and Commercial |

| Expected Lifespan | 15-20 Years |

| Weight | 50 kg |

| Cost Range | $300 - $1000 |

Why Consider Heat Exchanger In Heat Pump Guarantees Peak Performance Ahead of the Curve

A

Ava Hall

Top-notch quality! The support team is very competent and helped resolve my issues swiftly.

21 May 2025

A

Abigail Scott

Amazing product! The quality surpassed my expectations, and the support team was incredibly responsive.

25 May 2025

J

Jack Adams

This is a product of high quality. The after-sales service team was very knowledgeable and assisted me effectively.

26 June 2025

M

Mia Howard

Unbelievable quality! The customer service team went the extra mile to ensure my satisfaction.

24 May 2025

H

Henry Reyes

Superb quality and excellent customer support! The team was very accommodating and knowledgeable.

18 May 2025

E

Ella Hernandez

Absolutely wonderful quality! The support team was approachable and very helpful throughout.

08 June 2025