Corrosion Resistant Copper Fin Heat Exchanger - Factory & Suppliers in China

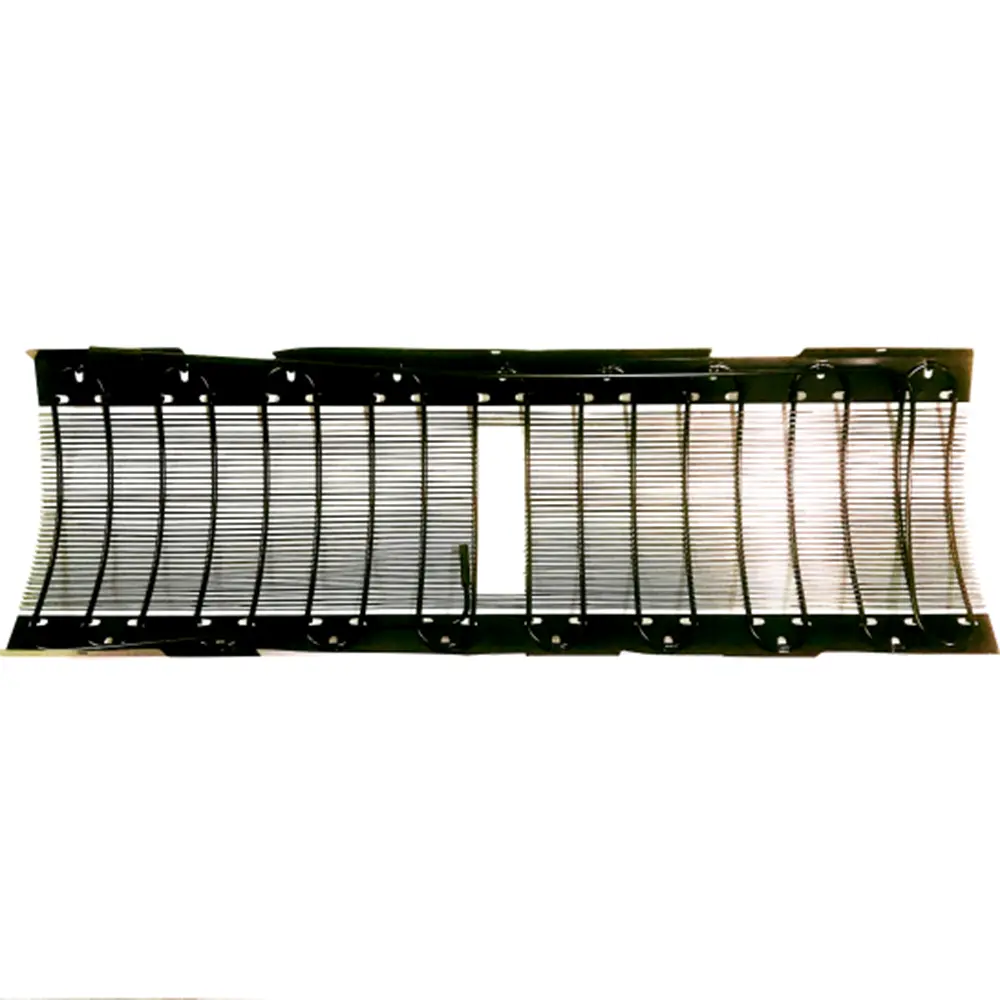

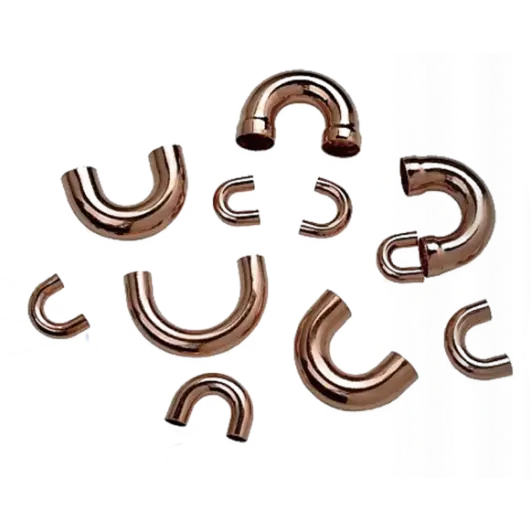

Ningbo Senjun New Materials Co., Ltd. proudly presents its Corrosion Resistant Copper Fin Heat Exchanger, crafted to meet the demanding needs of various industrial applications. Engineered with advanced technology, this heat exchanger ensures superior performance and extended durability, safeguarding against the corrosive effects of harsh environments, Designed with high-quality copper fins, it promotes optimal heat transfer efficiency while significantly reducing maintenance costs, making it an ideal choice for HVAC systems, refrigeration, and other thermal management solutions. The innovative design allows for easy installation and compatibility with different systems, ensuring seamless integration, With a commitment to quality, our products undergo stringent testing to meet international standards, guaranteeing reliability and longevity. Trust Ningbo Senjun New Materials Co., Ltd. for efficient energy solutions that enhance productivity while minimizing operational downtime. Experience the combination of innovation and resilience with our Corrosion Resistant Copper Fin Heat Exchanger, the perfect choice for modern industrial challenges

Top 10 Corrosion Resistant Copper Fin Heat Exchanger Trusted by Pros Where Innovation Meets 2025

In the fast-evolving world of HVAC and refrigeration, choosing the right components is crucial for efficiency and longevity. Among the key players in this industry are copper fin heat exchangers, renowned for their excellent thermal conductivity and corrosion resistance. At Ningbo Senjun New Materials Co., Ltd., we have taken innovation a step further with our top 10 corrosion-resistant copper fin heat exchangers, a range trusted by professionals worldwide. Our products are specifically designed to withstand harsh environments while ensuring optimal performance, thus enhancing the reliability of systems in refrigerators, freezers, drinking fountains, and display cabinets. Founded in 2010, we are dedicated to the rigorous research and development of next-generation wire tube condensers and heat exchangers. Our commitment to quality and innovation ensures that all our products meet the highest industry standards. As we look ahead to 2025, we continue to integrate advanced materials and cutting-edge technology into our designs, making our heat exchangers not only efficient but also sustainable. By choosing our copper fin heat exchangers, global buyers can leverage our expertise and market-leading solutions to enhance their product offerings and stay ahead in a competitive landscape.

Top 10 Corrosion Resistant Copper Fin Heat Exchanger Trusted by Pros Where Innovation Meets 2025

| Model | Material | Corrosion Resistance | Efficiency Rating | Weight (kg) |

|---|---|---|---|---|

| Model A | Copper-Nickel Alloy | Excellent | A++ | 12 |

| Model B | Tin-Plated Copper | Very Good | A+ | 10 |

| Model C | Phosphorus Deoxidized Copper | Good | A | 15 |

| Model D | Bronze Copper | Very Good | A+ | 14 |

| Model E | Copper-Tin Alloy | Excellent | A++ | 11 |

| Model F | Copper-Zinc Alloy | Good | A | 13 |

| Model G | Copper-Silver Alloy | Excellent | A++ | 9 |

| Model H | Copper-Aluminum Alloy | Very Good | A+ | 16 |

| Model I | Copper-Nickel-Tin Alloy | Excellent | A++ | 12 |

| Model J | Copper-Cobalt Alloy | Very Good | A+ | 14 |

Smart Ways To Corrosion Resistant Copper Fin Heat Exchanger Supplies the World’s Top Brands Guarantees Peak Performance

A

Ava Hall

Top-notch quality! The support team is very competent and helped resolve my issues swiftly.

21 May 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

G

Gabriel Washington

The product quality is outstanding. The after-sales team was impressive, very knowledgeable, and easy to work with.

06 June 2025

D

Dylan Ross

This product is fantastic! The support team provided exceptional guidance and assistance.

02 June 2025

E

Emma Watson

Overall, a great experience! The quality is impressive, and the customer service was very accommodating.

31 May 2025

L

Lucas Turner

What a great product! Quality is outstanding, and the customer service was very professional.

06 June 2025