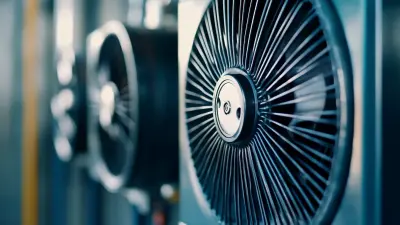

Condenser For Freezer: Top China Manufacturers & Factories

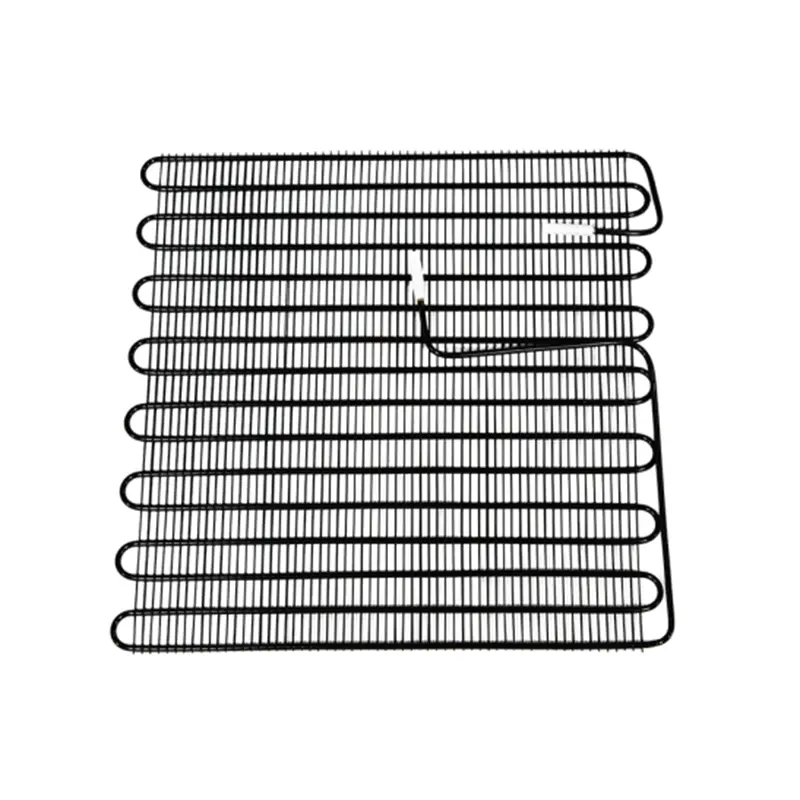

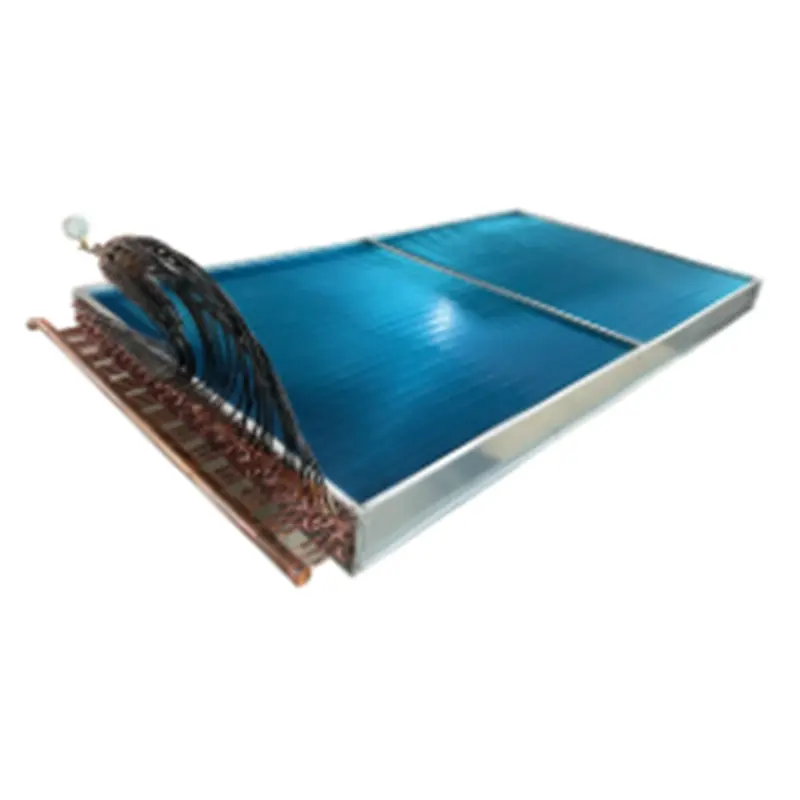

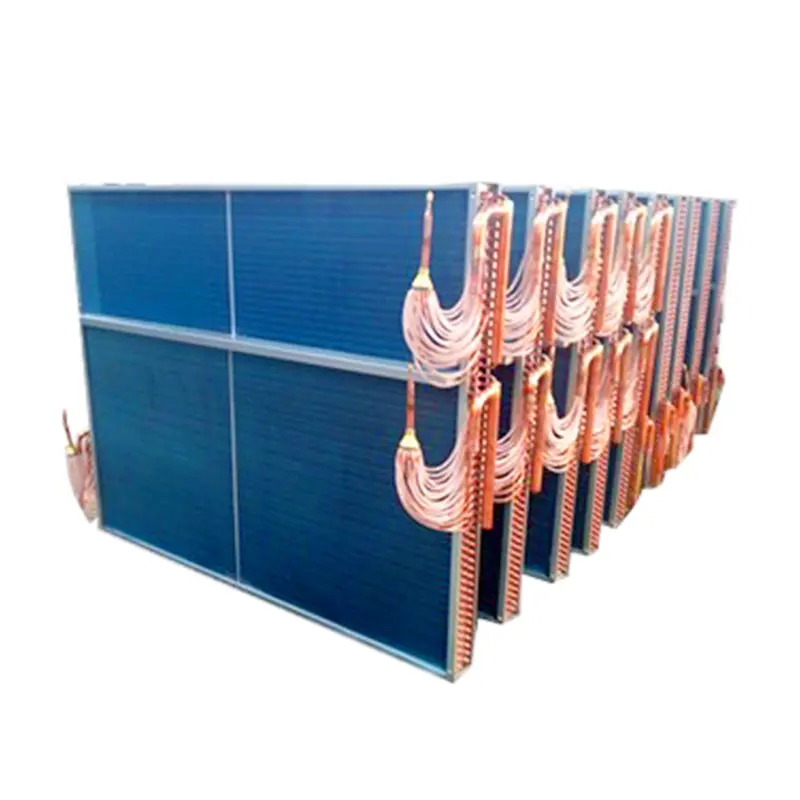

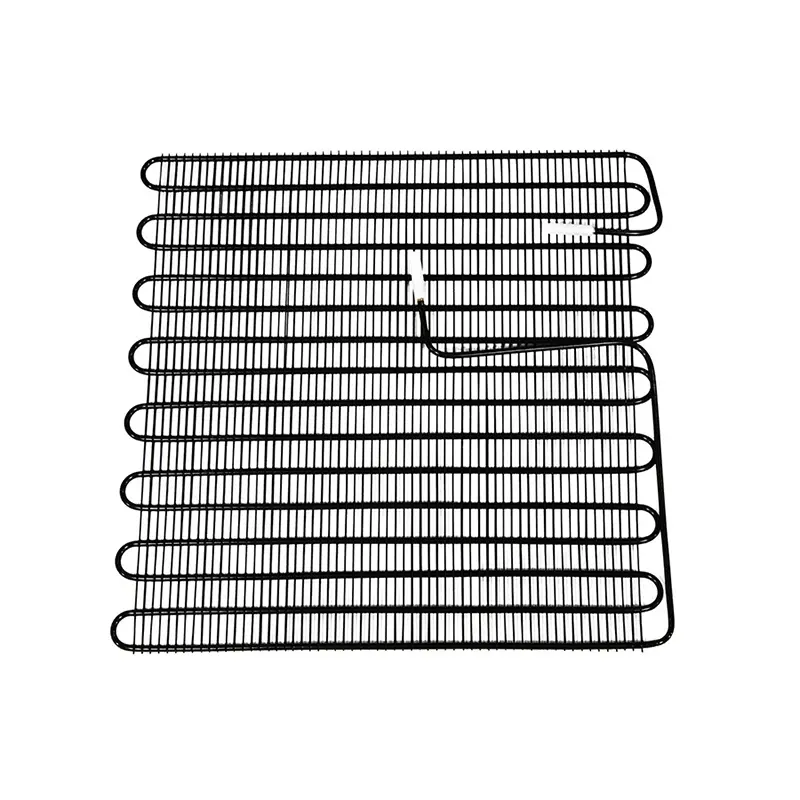

Ningbo Senjun New Materials Co., Ltd. proudly presents its advanced Condenser for Freezer solutions, designed to enhance the efficiency and performance of refrigeration systems. Our condensers are engineered using high-quality materials, ensuring optimal heat exchange and energy savings, With a focus on durability and reliability, these condensers cater to various freezer applications, from commercial units to residential models. The superior design facilitates quick installation and maintenance, providing convenience for manufacturers and end-users alike, Our condensers are rigorously tested to meet industry standards, demonstrating exceptional cooling capabilities while minimizing environmental impact. By choosing our products, customers benefit from enhanced freezer performance and prolonged equipment lifespan, Experience the perfect balance of innovation and functionality with Ningbo Senjun’s Condenser for Freezer, where quality meets efficiency. Trust us to be your partner in delivering superior refrigeration solutions that drive business success and customer satisfaction

Step-by-Step Guide Condenser For Freezer Application From Concept to Delivery

At Ningbo Senjun New Materials Co., Ltd., we understand that developing a condenser for freezer applications involves more than just technical specifications; it's a journey from concept to delivery. Since our establishment in 2010, we have dedicated ourselves to the research, development, and production of high-quality wire tube condensers and copper-aluminum fin heat exchangers. Our products are used across various sectors, including refrigerators, freezers, drinking fountains, and display cabinets, ensuring efficient cooling solutions for businesses worldwide. The journey begins with understanding your unique requirements and the specific application of the condenser. Our expert team collaborates closely with clients to design custom solutions tailored to their needs. We leverage advanced technology and materials to ensure that our condensers not only meet but exceed industry standards, providing reliability and efficiency. From the initial concept phase, we move to prototyping and rigorous testing, ensuring optimal performance under diverse conditions. As we transition from development to delivery, we prioritize transparency and communication. Our streamlined production process, backed by state-of-the-art facilities, guarantees timely delivery while maintaining high quality. By choosing Ningbo Senjun, you are not only investing in superior products but also in a partnership that supports your business objectives. Whether you're a manufacturer or a distributor, our condensers can elevate your product offerings, enhancing energy efficiency and customer satisfaction. Let us help you turn your vision into reality with our step-by-step guide to condenser solutions for freezer applications.

Step-by-Step Guide Condenser For Freezer Application From Concept to Delivery

| Step | Description | Duration | Responsible | Status |

|---|---|---|---|---|

| 1 | Define project requirements | 1 week | Project Manager | Completed |

| 2 | Concept design and feasibility study | 2 weeks | Design Engineer | In Progress |

| 3 | Prototype development | 3 weeks | Development Team | Pending |

| 4 | Testing and validation | 2 weeks | Quality Assurance | Pending |

| 5 | Final production preparation | 1 week | Production Manager | Pending |

| 6 | Delivery to client | 1 week | Logistics Coordinator | Pending |

Don't Miss These Condenser For Freezer Guarantees Peak Performance Is The Best

E

Ella Gomez

This product has great durability! The after-sales support was very professional and attentive.

02 June 2025

O

Olivia White

Very high quality. The support team was quick to assist and very knowledgeable.

26 May 2025

L

Lily Carter

Incredible quality with a flawless design! The after-sales team was very supportive and attentive.

16 May 2025

C

Carter Walker

Excellent product all around! The quality is phenomenal, and the support team was exceptionally helpful.

07 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025