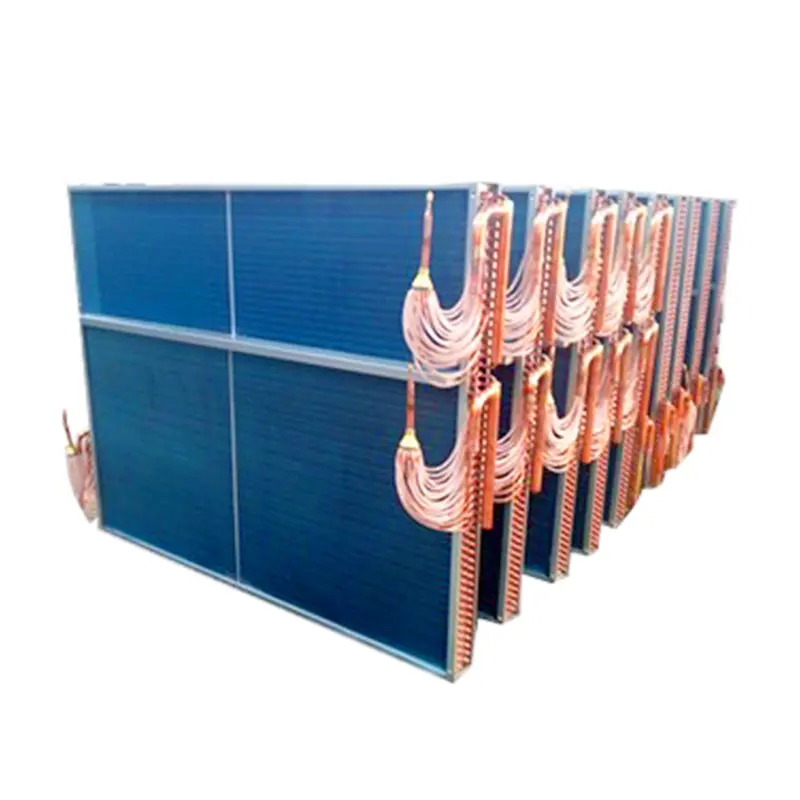

Wholesale Condenser Coil Heat Exchanger Factories & Suppliers

As a professional supplier of **Condenser Coil Heat Exchanger**, I focus on providing high-quality products tailored to meet the needs of various industries. Our factory specializes in manufacturing durable and efficient heat exchangers, ensuring optimal performance and longevity. Whether you are a wholesaler or a business seeking reliable manufacturers, my commitment is to deliver exceptional value and service, I understand the importance of finding a trustworthy supplier, and that’s why we strive to exceed your expectations with each order. From design to production, I take pride in our rigorous quality control processes. Partnering with **Ningbo Senjun New Materials Co., Ltd.**, you can expect personalized support that aligns with your specific requirements. Let’s connect and explore how we can fulfill your heat exchanger needs efficiently and affordably. Together, we can drive your business forward with high-performing solutions that enhance your operations

10 tips Condenser Coil Heat Exchanger Factories Industry Leaders Custom Solutions,

In the ever-evolving landscape of refrigeration and cooling solutions, heat exchangers play a pivotal role in enhancing efficiency and performance. At Ningbo Senjun New Materials Co., Ltd., we understand the critical need for high-quality condensers and heat exchangers tailored to meet specific industry requirements. Here are 10 essential tips for procurement professionals seeking custom solutions from industry leaders like us. Firstly, evaluate your needs by considering the type of application—whether it's for refrigerators, freezers, or display cabinets—ensures you acquire the right product. Next, collaborating with manufacturers that prioritize research and development can significantly impact the efficiency of your cooling systems. Moreover, partner with a factory that uses high-quality materials, such as copper and aluminum, to maximize durability and performance in various conditions. Don't overlook the importance of customization. A reputable manufacturer will offer bespoke solutions that cater to your operational demands. Additionally, ensure that your supplier conducts thorough testing and quality checks on their products, which is essential for maintaining reliability in performance. By choosing Ningbo Senjun New Materials Co., Ltd., you benefit not just from our top-notch products but also from our commitment to innovation and customer satisfaction. Let us help you achieve optimal cooling solutions that exceed expectations.

10 Tips for Condenser Coil Heat Exchanger Factories Industry Leaders Custom Solutions

| Tip No. | Tip Description | Benefits | Implementation Feasibility |

|---|---|---|---|

| 1 | Optimize coil design for enhanced airflow | Increases efficiency and performance | High feasibility with modern tools |

| 2 | Implement customized material selection | Improves durability and resistance | Moderate feasibility, requires supplier collaboration |

| 3 | Enhance heat transfer efficiency with coatings | Provides better thermal conductivity | High feasibility with available technologies |

| 4 | Utilize simulation software for design validation | Reduces design errors and rework | High feasibility with investment in software |

| 5 | Regular maintenance and cleaning schedules | Increases lifespan and efficiency | High feasibility with proper planning |

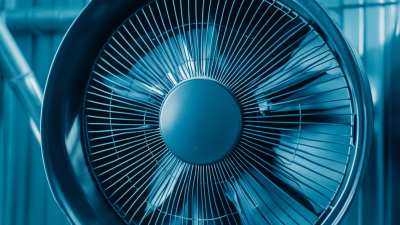

| 6 | Incorporate variable speed fans | Enhances energy savings and control | Moderate feasibility, requires system update |

| 7 | Integrate IoT sensors for monitoring | Enables real-time performance tracking | Moderate feasibility with technology investment |

| 8 | Conduct regular staff training | Improves operational efficiency | High feasibility with minimal cost |

| 9 | Design for easy access and maintenance | Reduces downtime and maintenance costs | Moderate feasibility during design phase |

| 10 | Evaluate and adopt innovative technologies | Keeps the factory competitive and efficient | Variable feasibility depending on resources |

Avoiding Pitfalls Condenser Coil Heat Exchanger Factories Exceeds Industry Benchmarks Industry Giant

B

Brian Chen

This product is fantastic! The quality is really high, and their customer service was professional and quite helpful.

23 June 2025

S

Samuel Carter

I can’t get over the quality! The customer service team was incredibly professional and responsive.

17 May 2025

S

Sophia Young

Excellence in both product and service! The after-sales team provided the assistance I needed.

20 May 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025