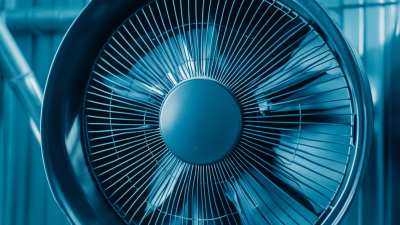

Wholesale Condensation Heat Exchanger from Trusted Factory Manufacturer

The Condensation Heat Exchanger by Ningbo Senjun New Materials Co., Ltd. is designed for optimal efficiency in thermal energy transfer, making it an essential component for various industrial applications. This advanced heat exchanger utilizes the process of condensation to reclaim and transfer heat from exhaust gases or other fluids, significantly enhancing energy conservation and reducing operational costs, Crafted with high-quality materials, it offers exceptional durability and resistance to corrosion, ensuring a long service life even in demanding environments. The innovative design promotes effective Heat Transfer, maximizing performance while minimizing energy loss, Ideal for use in HVAC systems, power plants, and chemical processing, our Condensation Heat Exchanger plays a crucial role in improving overall system efficiency. With a commitment to sustainability and cutting-edge technology, Ningbo Senjun New Materials Co., Ltd. continues to deliver solutions that meet the evolving needs of modern industries. Choose our Condensation Heat Exchanger for a reliable, efficient, and eco-friendly thermal management solution

Cutting-Edge Condensation Heat Exchanger Application More Than a Supplier - A Partner

In today's competitive market, finding a reliable partner for your heat exchanger needs is essential for the success of your business. Ningbo Senjun New Materials Co., Ltd. stands out as a pioneering force in the field of wire tube condensers and copper-aluminum fin heat exchangers since its inception in 2010. Our commitment to innovation and quality ensures that our products meet the highest standards, whether they are used in refrigerators, freezers, drinking fountains, or display cabinets. What sets us apart is not just our ability to supply high-performance products but our focus on collaboration and partnership. We understand the unique challenges faced by global purchasers, and we prioritize building long-lasting relationships that enhance operational efficiency and drive mutual growth. By working closely with our clients, we tailor our solutions to meet specific requirements, ensuring optimal performance and reliability in diverse applications. With a dedicated R&D team and a robust production process, Ningbo Senjun New Materials Co., Ltd. is more than just a supplier; we strive to be your trusted partner in navigating the complexities of the heat exchanger industry. Our innovative approach and commitment to customer satisfaction empower you to elevate your business while benefiting from state-of-the-art technology and expertise. Let us work together to achieve excellence in your cooling solutions.

Cutting-Edge Condensation Heat Exchanger Application More Than a Supplier - A Partner

| Application Area | Technology Used | Efficiency (%) | Heat Recovery Potential (kW) | Partnership Benefits |

|---|---|---|---|---|

| Industrial Refrigeration | Plate Heat Exchanger | 90 | 150 | Reduced energy costs |

| Power Generation | Shell and Tube Heat Exchanger | 85 | 200 | Increased output |

| HVAC Systems | Vacuum Heat Exchanger | 88 | 120 | Improved comfort levels |

| Food Processing | Double Pipe Heat Exchanger | 92 | 100 | Enhanced product quality |

| Chemical Processing | Spiral Heat Exchanger | 87 | 175 | Optimized process control |

Top 3 Condensation Heat Exchanger Your End-to-End Solution From Concept to Delivery

D

Daniel Clark

High-quality product with an impressive finish. The support team was very knowledgeable and addressed my concerns promptly.

16 June 2025

S

Scarlett Martinez

This product is of outstanding quality! The after-sales support staff were knowledgeable and eager to help.

18 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

O

Olivia Moore

Very pleased with my purchase! The product quality is great, and the customer service was exemplary.

09 June 2025

A

Avery Baker

Superb product quality and excellent customer service! The support staff was very knowledgeable.

05 July 2025

J

Joshua Campbell

Fantastic craftsmanship! The after-sales service was prompt and the staff was very competent.

08 May 2025