Wholesale Cold Storage Heat Exchanger Manufacturers & Factories Online

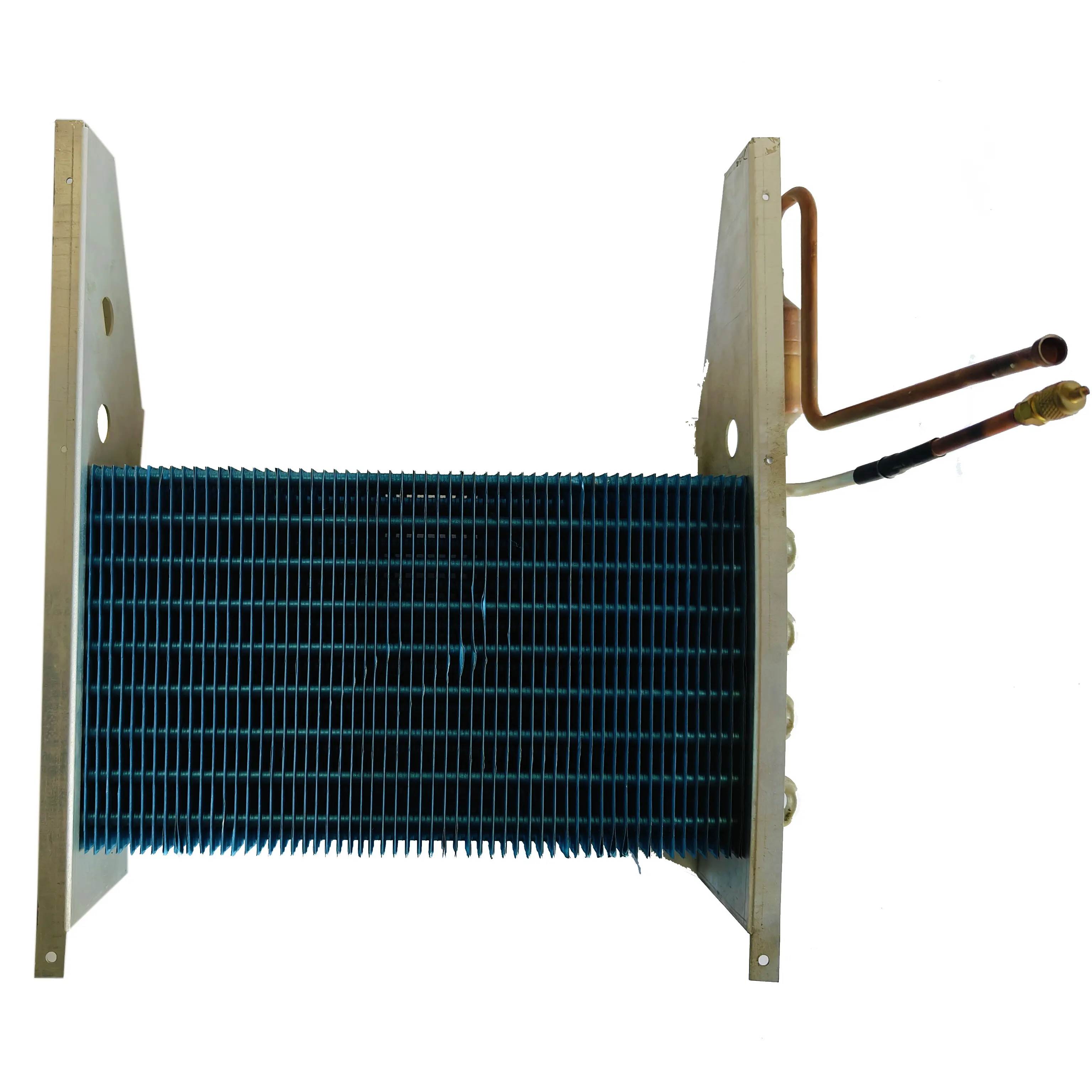

Discover the innovative Cold Storage Heat Exchanger by Ningbo Senjun New Materials Co., Ltd., designed to optimize thermal efficiency in a variety of applications. This advanced heat exchanger is engineered to ensure effective temperature regulation, making it ideal for cold storage facilities, refrigeration systems, and industrial processes requiring precise thermal management, Constructed with high-quality materials, our heat exchanger boasts excellent durability and corrosion resistance, providing long-lasting performance even under demanding conditions. The design features enhanced Heat Transfer capabilities, reducing energy consumption while maintaining optimal cooling performance. With easy installation and maintenance, this solution aligns seamlessly with modern energy efficiency goals, Ningbo Senjun New Materials Co., Ltd. is committed to delivering cutting-edge technology and exceptional service. Our Cold Storage Heat Exchanger not only meets industry standards but also represents a significant step toward sustainable practices in temperature-sensitive environments. Transform your cold storage solutions with our reliable and efficient heat exchangers, tailored to maximize your operational effectiveness

Step-by-Step Guide To Cold Storage Heat Exchanger Your Trusted OEM Partner Products

When it comes to optimizing the efficiency of cold storage systems, selecting the right heat exchanger is crucial. At Ningbo Senjun New Materials Co., Ltd., we specialize in designing and manufacturing top-quality wire tube condensers and copper aluminum fin heat exchangers tailored for a variety of applications, including refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to innovation and quality since our establishment in 2010 has positioned us as a trusted OEM partner for clients worldwide. In this step-by-step guide, we will walk you through the essential features to consider when sourcing cold storage heat exchangers. First, evaluate the material composition; our heat exchangers utilize durable copper and aluminum, ensuring superior thermal performance and corrosion resistance. Next, consider the specific requirements of your cooling systems—be it size, capacity, or application type. Our engineering team is dedicated to customizing products to meet precise specifications, thereby enhancing energy efficiency and performance. Lastly, partnering with an experienced manufacturer like Ningbo Senjun means you gain access to unparalleled support throughout the procurement process. From initial consultation to after-sales service, we are committed to ensuring that your systems operate optimally. Trust us to be your OEM partner for high-quality heat exchanger solutions, empowering your business with reliable and cost-effective products that meet the demands of a competitive global market.

Step-by-Step Guide To Cold Storage Heat Exchanger Your Trusted OEM Partner Products

| Feature | Specification | Benefits | Applications |

|---|---|---|---|

| Material | Stainless Steel | Corrosion resistance and durability | Food and Beverage, Chemical Processing |

| Heat Transfer Area | 200 m² | Efficient cooling performance | Cold Storage, HVAC systems |

| Design Type | Plate and Frame | Compact design, easy maintenance | Refrigeration, Industrial |

| Temperature Range | -40°C to 85°C | Versatile for various applications | Pharmaceutical, Cryogenic |

| Flow Rate | 100 m³/h | Increased throughput, improved efficiency | Cooling Towers, Process Industries |

China Top Cold Storage Heat Exchanger Is The Best Supplier

M

Megan Lewis

I’m very happy with my purchase. The product quality is superb, and the after-sales service was incredibly helpful.

10 May 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

L

Lucas Phillips

Impressive craftsmanship! The customer service team is knowledgeable and always willing to help.

26 May 2025

A

Ava Nguyen

Amazing quality and superb service! The support team was incredibly knowledgeable.

15 May 2025

M

Mia Thompson

The product is fantastic! The quality stands out, and the service team was very helpful throughout.

04 June 2025

L

Lucas Robinson

Impressive quality! Their customer service team is well-trained and very responsive.

09 May 2025