Wholesale Air Cooled Heat Exchangers from Trusted Factories & Suppliers

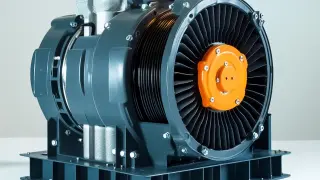

Ningbo Senjun New Materials Co., Ltd. proudly presents its state-of-the-art Air Cooled Heat Exchanger, engineered to enhance thermal efficiency in various industrial applications. Designed for optimal performance, this heat exchanger utilizes ambient air to dissipate heat from process fluids, ensuring reliable temperature control without the need for additional water resources, Crafted from high-quality materials, it offers exceptional durability and resistance to corrosion, making it ideal for challenging environments. The innovative design features increased surface area for enhanced Heat Transfer, resulting in energy savings and improved operational efficiency, Whether used in petrochemical, power generation, or HVAC systems, our Air Cooled Heat Exchanger stands out for its reliable performance and low maintenance requirements. With a commitment to sustainability, this solution not only reduces water consumption but also minimizes environmental impact. Trust Ningbo Senjun to deliver cutting-edge solutions that meet the demands of modern industry while maintaining the highest standards of quality and performance

10 Essential Tips For Air Cooled Heat Exchanger Sets the Industry Standard Industry Leaders

In today's competitive market, the efficiency and reliability of air-cooled heat exchangers are paramount for industries seeking to optimize their operations. Ningbo Senjun New Materials Co., Ltd. has established itself as a leader in producing innovative heat transfer solutions since 2010. Our focus on research and development has yielded high-performance wire tube condensers and copper-aluminum fin heat exchangers that are widely used in refrigerators, freezers, drinking fountains, and display cabinets. To set the industry standard, it is essential to understand key factors that contribute to the effectiveness of heat exchangers. Firstly, selecting the right materials is crucial. Utilizing advanced copper and aluminum alloys enhances thermal conductivity and durability, ensuring long-lasting performance. Secondly, the design and configuration of the heat exchanger impact its efficiency; optimized airflow and heat transfer surfaces can significantly improve cooling capacity while reducing energy consumption. Moreover, maintenance plays a vital role in sustaining performance over time. Regular cleaning and inspections are necessary to prevent fouling and ensure optimal operation. Collaborating with trusted manufacturers like Ningbo Senjun not only provides access to cutting-edge technology but also ensures compliance with stringent industry standards. By implementing these essential tips, global purchasers can not only enhance their product performance but also achieve sustainable operational efficiencies.

10 Essential Tips For Air Cooled Heat Exchanger Sets the Industry Standard Industry Leaders

| Tip Number | Tip Description | Expected Benefit | Implementation Time |

|---|---|---|---|

| 1 | Choose the right fin design | Improved heat transfer efficiency | 1 week |

| 2 | Regular maintenance checks | Extended equipment lifespan | Ongoing |

| 3 | Optimize airflow patterns | Maximized cooling performance | 2 days |

| 4 | Implement corrosion protection measures | Reduced maintenance costs | 1 week |

| 5 | Utilize advanced control systems | Enhanced operational efficiency | 2 weeks |

| 6 | Select high-quality materials | Durability and reliability | 1 month |

| 7 | Ensure proper sizing of exchangers | Optimal heat transfer | 3 days |

| 8 | Implement a data monitoring system | Real-time performance analysis | 1 week |

| 9 | Train staff for optimal operation | Increased safety and efficiency | 2 days |

| 10 | Conduct regular performance assessments | Continuous improvement | Ongoing |

Top Picks For Air Cooled Heat Exchanger Global Reach Dominates

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

R

Ryan Turner

I’m very satisfied! The item quality is great, and the after-sales service was attentive and professional.

23 June 2025

E

Emma Allen

I love the quality of this product. The customer service representatives were also extremely helpful and proactive!

10 May 2025

L

Liam Young

Incredible quality and a helpful customer support team! They made sure my experience was smooth and satisfying.

19 June 2025

L

Lucas Hall

This product is fantastic! Their support team is responsive and genuinely cares about customer satisfaction.

13 June 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025