4 Components of Refrigeration Factories in China: Top Manufacturers Guide

When it comes to understanding the 4 components of refrigeration factories, I highly value reliable suppliers from China. Being based in Ningbo, I’ve experienced firsthand how essential these components are for efficient operations. From compressors to condensers, evaporators, and expansion devices, each plays a crucial role in maintaining optimal temperatures and ensuring good productivity, My focus is on sourcing high-quality materials that meet international standards, ensuring your factory operates at peak performance. Partnering with experienced suppliers like us means you can expect timely delivery and support in scaling your production, Let’s collaborate to enhance your refrigeration systems and drive your business forward! It’s time to invest in the best components tailored for your needs. Reach out today to learn how our expertise can benefit your operations!

Effective Ways To 4 Components Of Refrigeration Factories Now Trending Guarantees Peak Performance

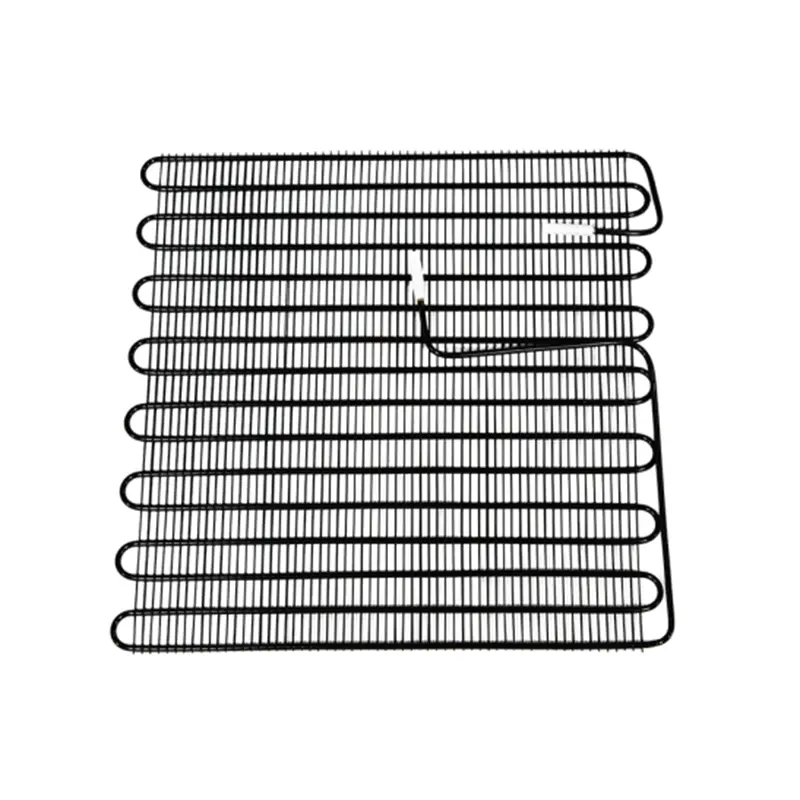

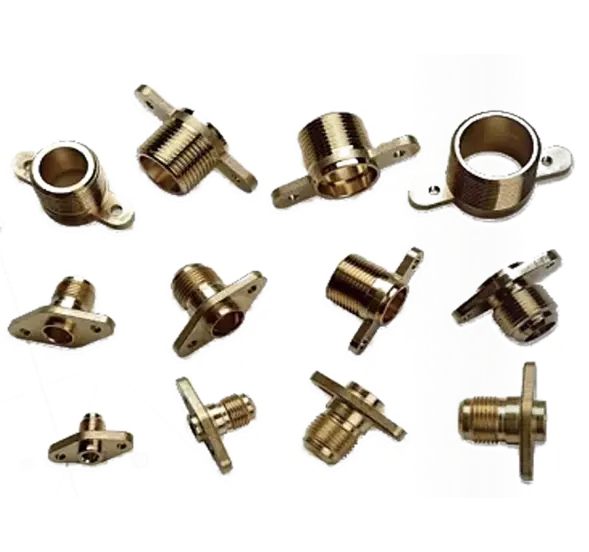

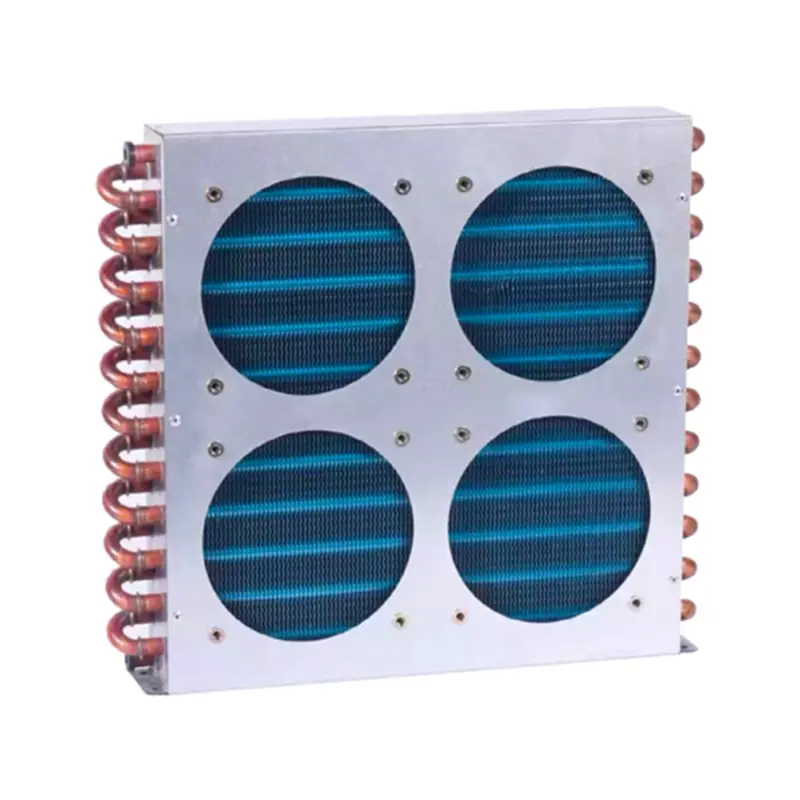

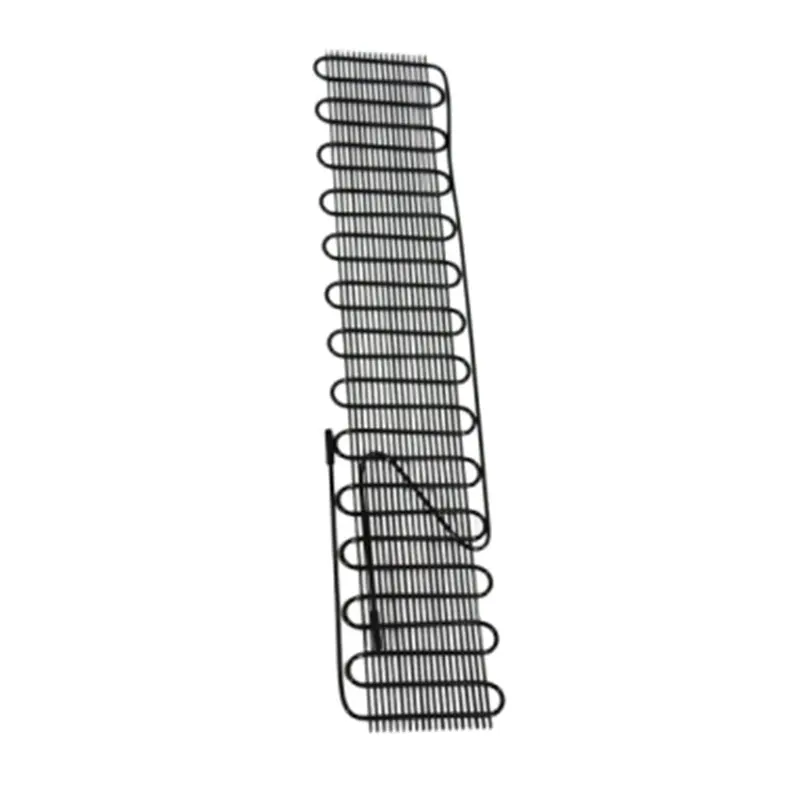

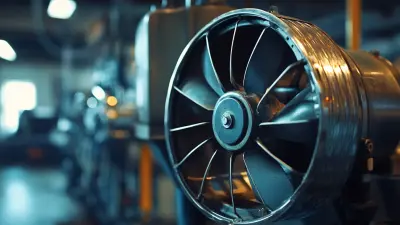

In the ever-evolving landscape of refrigeration technology, understanding the essential components that guarantee peak performance is crucial for manufacturers and businesses alike. At Ningbo Senjun New Materials Co., Ltd., we focus on the innovation and development of wire tube condensers and copper aluminum fin heat exchangers, integral parts of diverse refrigeration applications including refrigerators, freezers, and display cabinets. As we delve into the four trending components that are reshaping the industry, we'll uncover effective strategies to enhance efficiency and durability. First and foremost, the design of condensers has transformed significantly. Emphasizing streamlined airflow and thermal efficiency, our wire tube condensers are engineered to optimize refrigerant flow, resulting in improved cooling performance. Additionally, the integration of smart technology in heat exchangers is on the rise, enabling real-time monitoring and energy management that not only extends equipment lifespan but also reduces operational costs. By investing in these advanced technologies, procurement professionals can ensure their refrigeration systems meet the highest standards of performance and reliability. Moreover, sustainability is now a central focus in modern refrigeration manufacturing. The use of eco-friendly materials and refrigerants aligns with global environmental standards, making products not just efficient but also responsible. At Ningbo Senjun, our commitment to research and development underpins our ability to offer solutions that are both innovative and sustainable. Embracing these four components—advanced condenser design, smart technology integration, and sustainable practices—will undoubtedly position businesses to thrive in the competitive refrigeration market. By collaborating with us, global buyers can secure products that not only perform at their peak but also contribute positively to the environment.

Effective Ways To 4 Components Of Refrigeration Factories Now Trending Guarantees Peak Performance

| Component | Current Trends | Performance Metrics | Energy Efficiency Rating |

|---|---|---|---|

| Compressors | Inverter Technology | 12000 BTU/hr - 20000 BTU/hr | A++ |

| Evaporators | Microchannel Designs | Efficient Heat Transfer | A+ |

| Condensing Units | Variable Speed Fans | Minimized Operating Noise | A++ |

| Insulation Materials | Eco-friendly Options | Thermal Conductivity 0.022 W/m·K | A |

The Clear Choice of 4 Components Of Refrigeration Factories Factory Supplier

J

James Wilson

Exceptional quality! The after-sales service representatives were responsive and educated, making me feel valued.

18 June 2025

S

Sophia Martinez

I’m thrilled with this product! The quality is outstanding, and the customer service really goes above and beyond.

27 June 2025

S

Samuel Carter

I can’t get over the quality! The customer service team was incredibly professional and responsive.

17 May 2025

E

Ethan Fisher

Impressive quality! The after-sales support team was attentive and provided great service.

15 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

I

Isabella Edwards

This item is of superior quality! The customer support team was prompt and incredibly helpful.

03 June 2025