Wire and Tube Condenser Manufacturers in China: Explore Top Factories

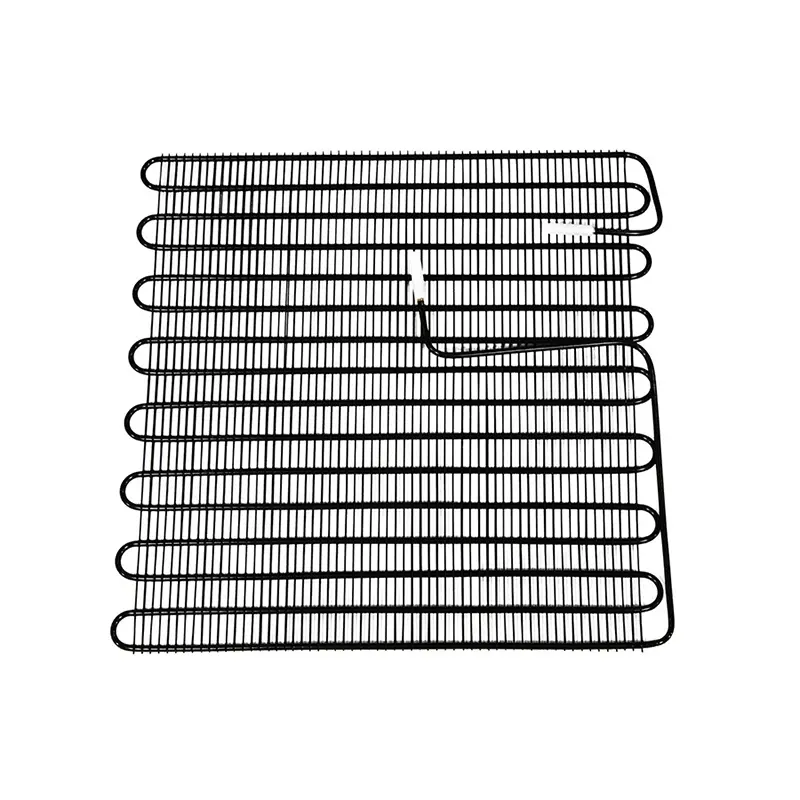

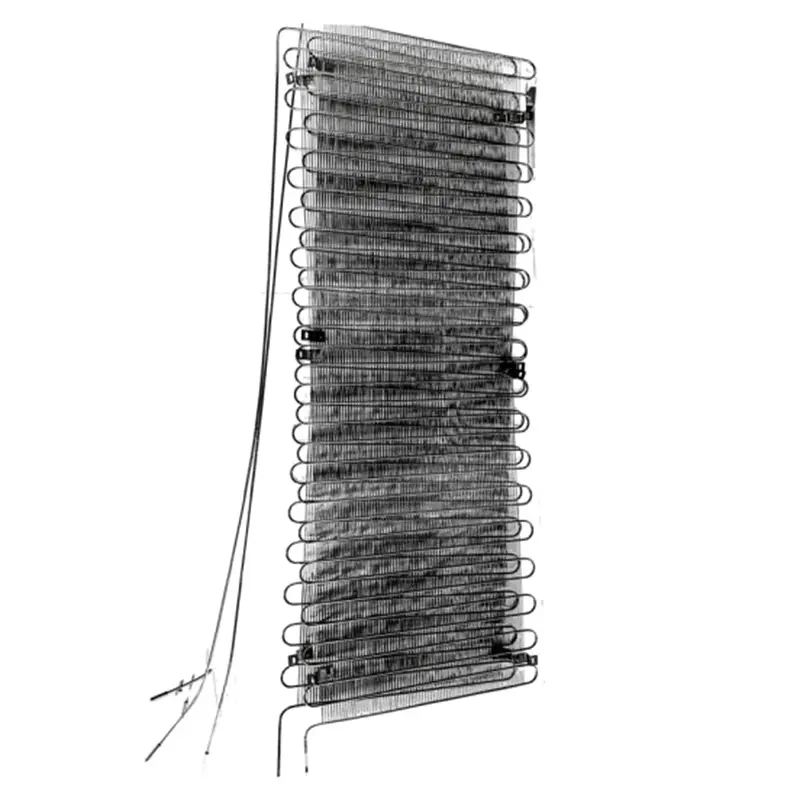

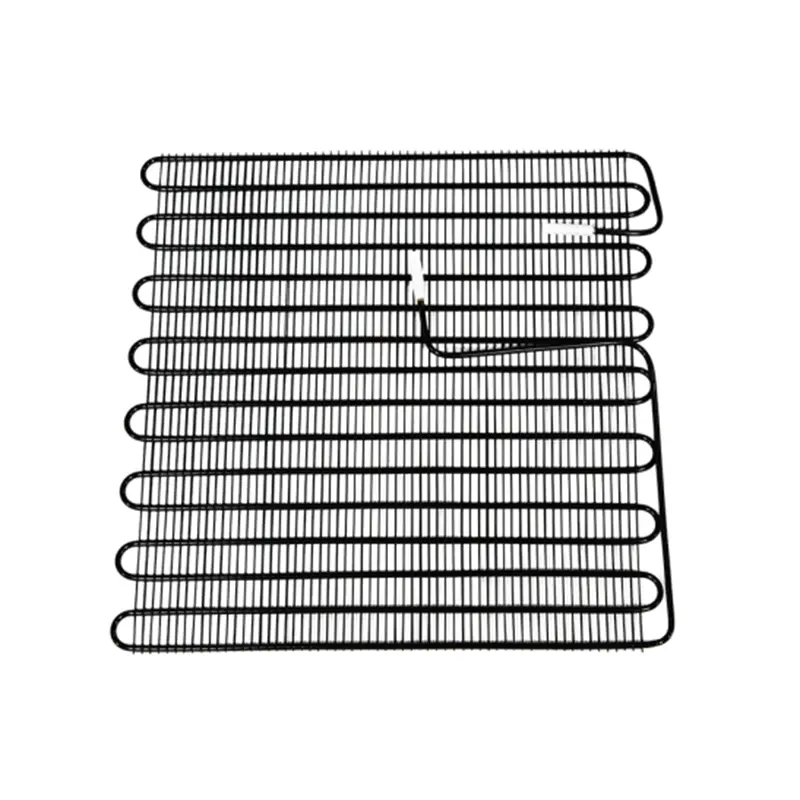

Discover the innovative Wire and Tube Condenser from Ningbo Senjun New Materials Co., Ltd., designed to enhance thermal efficiency and performance in various applications. This state-of-the-art condenser combines advanced engineering with high-quality materials to ensure optimal heat transfer, making it ideal for HVAC systems, refrigeration units, and industrial processes, The Wire and Tube Condenser features a robust construction that maximizes durability while minimizing energy consumption. Its unique design allows for efficient airflow and superior cooling capacity, contributing to reduced operational costs, Ningbo Senjun New Materials Co., Ltd. prides itself on delivering reliable and high-performance products tailored to meet specific customer needs. By focusing on innovation and sustainability, the Wire and Tube Condenser exemplifies the company's commitment to excellence in manufacturing and environmental responsibility, Choose Ningbo Senjun New Materials Co., Ltd. for your condenser solutions and experience unparalleled performance and efficiency for your applications

Exploring Wire And Tube Condenser Is The Best From Concept to Delivery

In today's competitive landscape, sourcing high-quality components like wire and tube condensers is crucial for manufacturers aiming to enhance their product efficiency and reliability. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on being at the forefront of this innovation. Established in 2010, we have dedicated ourselves to the research, development, and production of advanced wire tube condensers and copper aluminum fin heat exchangers, primarily for applications in refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to excellence ensures that we not only meet but exceed global standards, making our products the preferred choice for buyers across various industries. Our rigorous quality control processes guarantee that each condenser delivers optimal performance and longevity, which can significantly reduce maintenance costs and enhance customer satisfaction. By choosing Ningbo Senjun, global procurement professionals can rest assured they are partnering with a reliable source that understands the importance of quality from concept to delivery. As we continue to innovate and adapt to market needs, we invite global buyers to explore our extensive range of products tailored to meet diverse thermal management requirements. Our team is dedicated to providing expert guidance throughout the procurement process, ensuring that you find the perfect solutions for your needs. Join us in achieving excellence in your operations through our superior wire tube condensers and heat exchangers.

Exploring Wire And Tube Condenser Is The Best From Concept to Delivery

| Dimension | Material Used | Efficiency (%) | Weight (kg) | Cost (USD) |

|---|---|---|---|---|

| 200mm x 100mm x 50mm | Copper and Aluminum | 85 | 2.5 | 150 |

| 250mm x 150mm x 60mm | Copper and Stainless Steel | 90 | 3.2 | 180 |

| 300mm x 200mm x 70mm | Aluminum and Steel | 88 | 4.0 | 210 |

| 350mm x 250mm x 80mm | Copper | 92 | 5.5 | 250 |

Why China’s Wire And Tube Condenser Industry Leaders Industry Giant

S

Scarlett Baker

I’m thoroughly impressed! The quality is remarkable, and the customer service team provided excellent support.

31 May 2025

E

Ethan Fisher

Impressive quality! The after-sales support team was attentive and provided great service.

15 June 2025

I

Isabella Williams

High-quality product with helpful and responsive customer service! A truly satisfying experience.

13 May 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025