Wholesale Water Cooled Condenser Coil Manufacturers - Factory Supplier

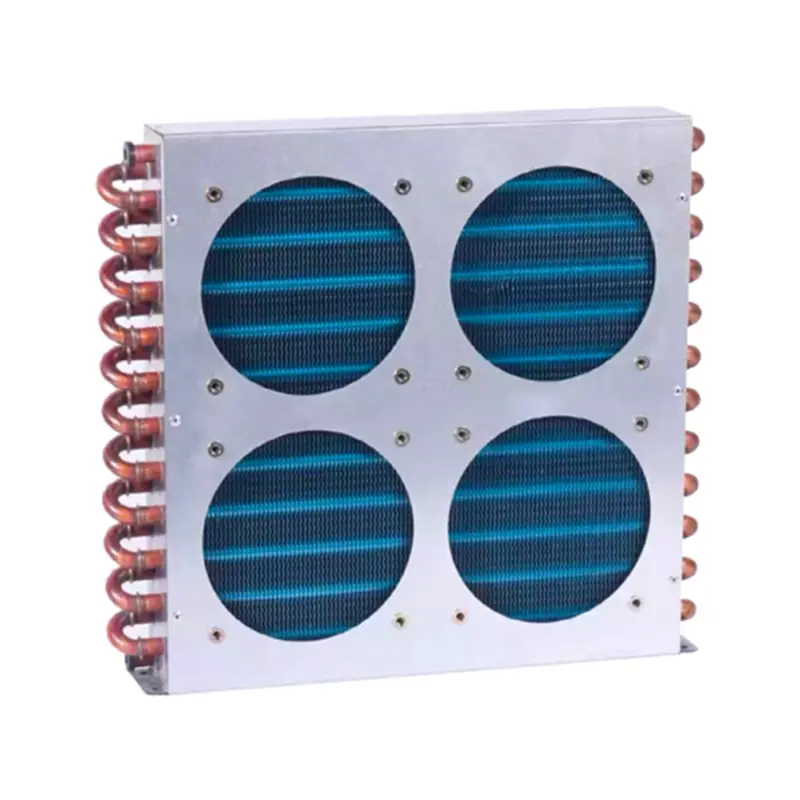

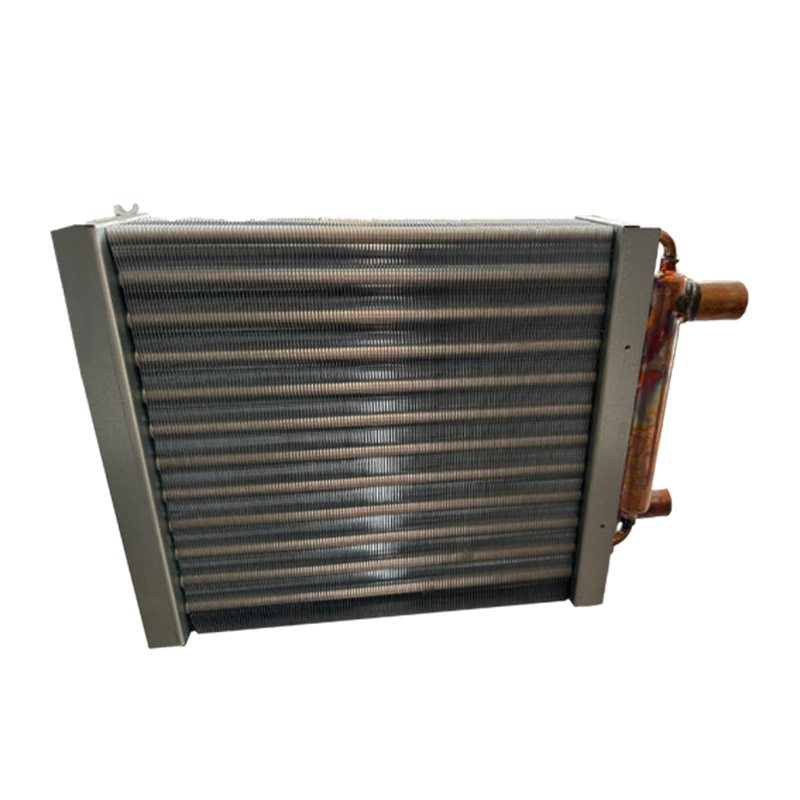

As a professional in the HVAC industry, I understand how crucial it is to find reliable water cooled Condenser Coil manufacturers. Our factory in Ningbo, China, specializes in producing high-quality coils designed to optimize thermal efficiency and durability. We take pride in using advanced materials and manufacturing techniques, ensuring our products meet the strictest industry standards, When you choose us, you’re not just getting a product; you’re getting a partner who values innovation and quality. Our expertise allows us to customize solutions that cater specifically to your needs, whether for large-scale projects or small-scale applications. Partnering with us means access to competitive pricing and exceptional customer service. Let’s connect and discuss how our water cooled condenser coils can enhance your operations and increase your business success. We’re here to support your needs every step of the way!

Best Practices For Water Cooled Condenser Coil Manufacturers From Concept to Delivery Sets the Industry Standard

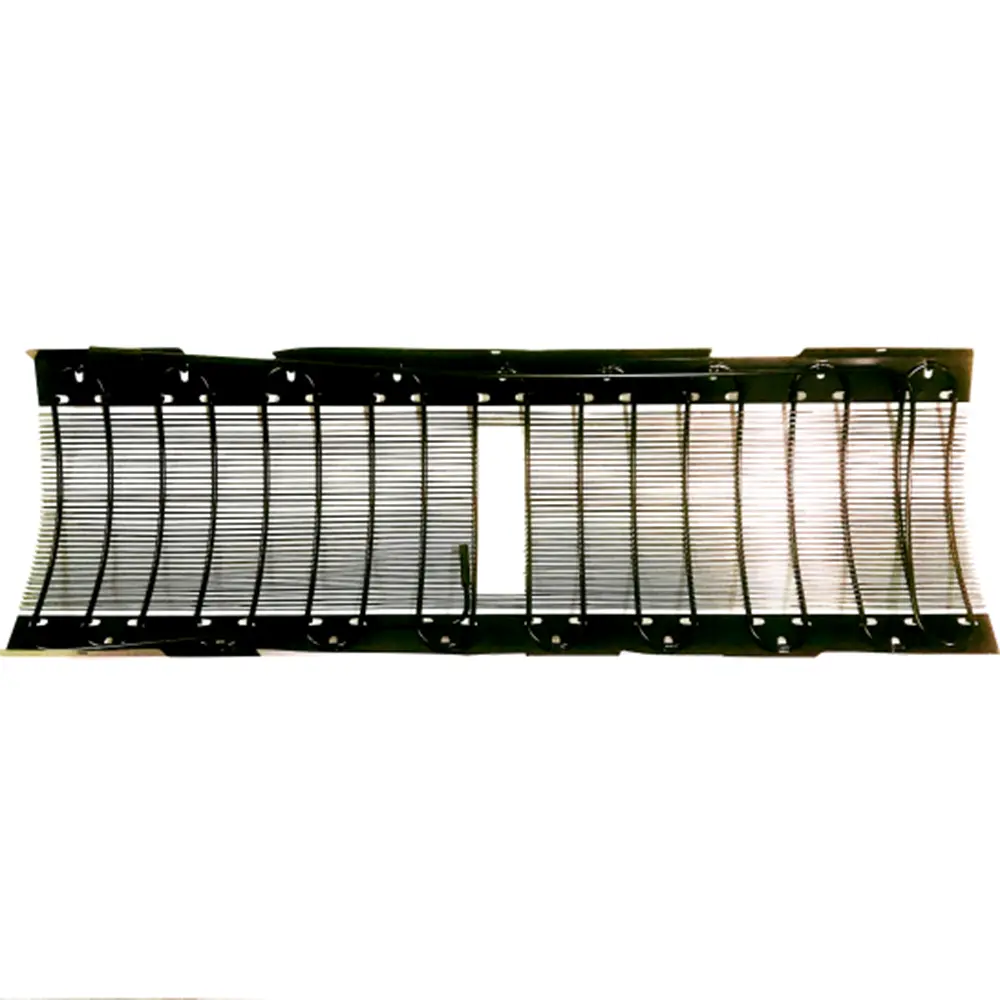

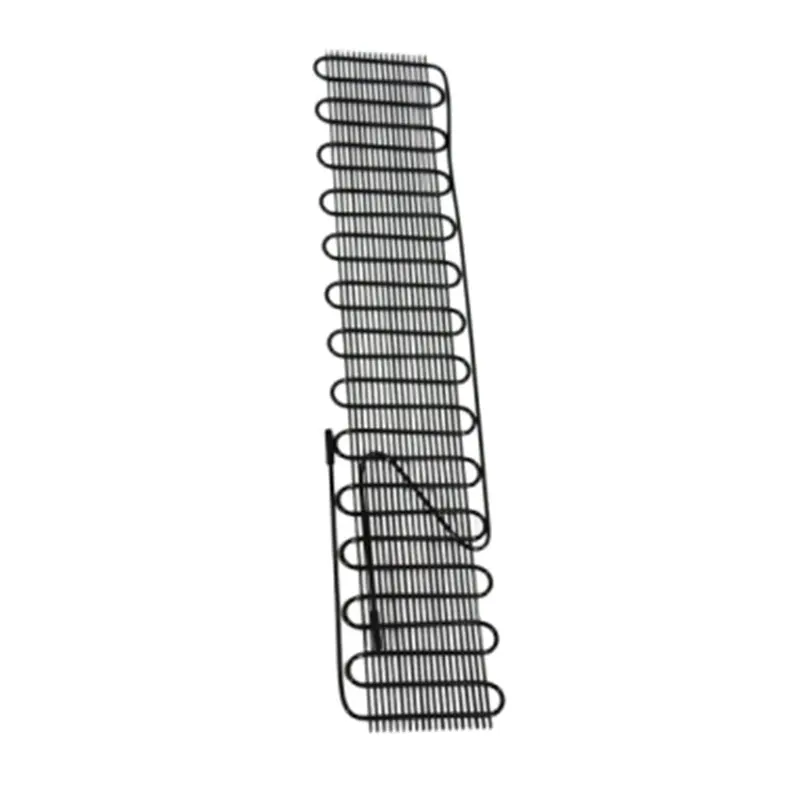

At Ningbo Senjun New Materials Co., Ltd., we believe that establishing best practices in the manufacturing of water-cooled condenser coils is essential for setting industry standards. Since our inception in 2010, we have dedicated ourselves to the meticulous research and development of high-quality wire tube condensers and copper-aluminum fin heat exchangers, which are critical components in a variety of applications including refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to quality and innovation ensures that we meet the evolving needs of global buyers. From concept to delivery, we follow stringent quality control measures and embrace advanced technologies to enhance product performance and durability. Our engineers work closely with clients to customize solutions that address specific requirements while maintaining efficiency. This collaboration not only improves design but also streamlines the production process. By continuously refining our manufacturing practices, we position ourselves as leaders in the market, capable of meeting the diverse demands of international customers. For global purchasers, understanding the importance of a reliable supply chain and adherence to industry standards is crucial. At Senjun, we prioritize transparency and communication throughout the procurement process, ensuring that our partners receive exceptional service and high-quality products. Our aim is to build long-term relationships, enabling businesses to thrive with superior cooling solutions that contribute to their success.

Best Practices For Water Cooled Condenser Coil Manufacturers From Concept to Delivery Sets the Industry Standard

| Best Practice | Description | Impact | Implementation Time (weeks) | Cost ($) |

|---|---|---|---|---|

| Material Selection | Choose high-quality corrosion-resistant materials for durability. | Increases lifespan and efficiency. | 4 | 5000 |

| Design Optimization | Utilize computer-aided design (CAD) for efficient layout. | Improves heat transfer and reduces energy costs. | 6 | 3000 |

| Quality Control | Implement stringent quality checks at every stage of production. | Reduces defects and improves customer satisfaction. | 3 | 2000 |

| Testing Procedures | Conduct rigorous testing to ensure performance criteria are met. | Enhances reliability and performance claims. | 2 | 1500 |

| Training Programs | Regular training for staff on new technologies and practices. | Improves workforce efficiency and knowledge. | 5 | 3500 |

Must-Choose Reasons Water Cooled Condenser Coil Manufacturers Now Trending Is The Best

A

Andrew Kim

Impressive product quality! The after-sales service team is top-notch, always willing to assist with any concerns.

20 June 2025

G

Gabriel Washington

The product quality is outstanding. The after-sales team was impressive, very knowledgeable, and easy to work with.

06 June 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

I

Isabella Edwards

This item is of superior quality! The customer support team was prompt and incredibly helpful.

03 June 2025

O

Olivia Moore

Very pleased with my purchase! The product quality is great, and the customer service was exemplary.

09 June 2025