Wholesale Shell & Tube Type Evaporator Supplier & Factories

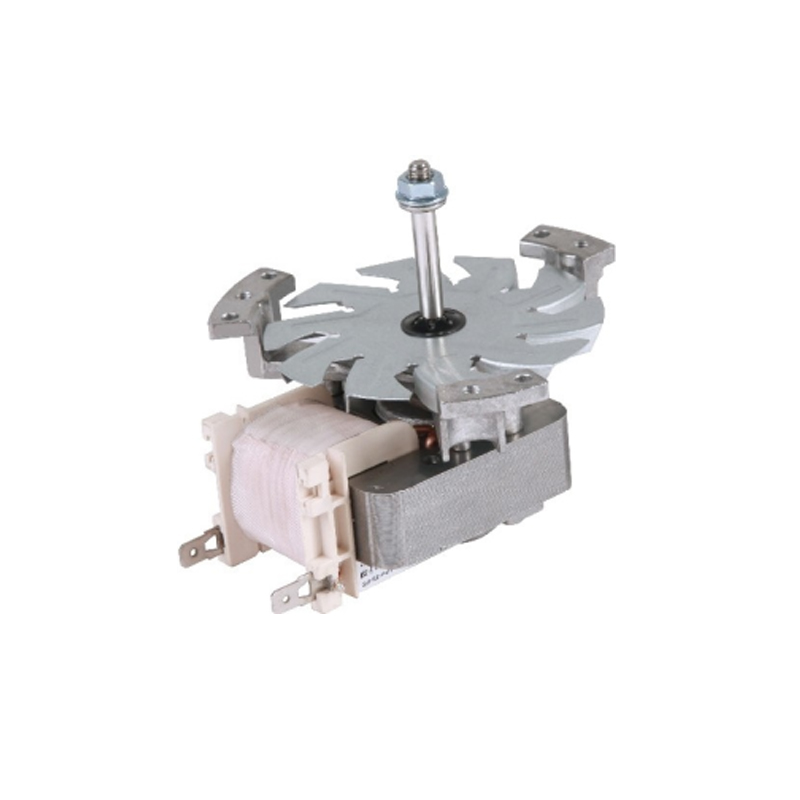

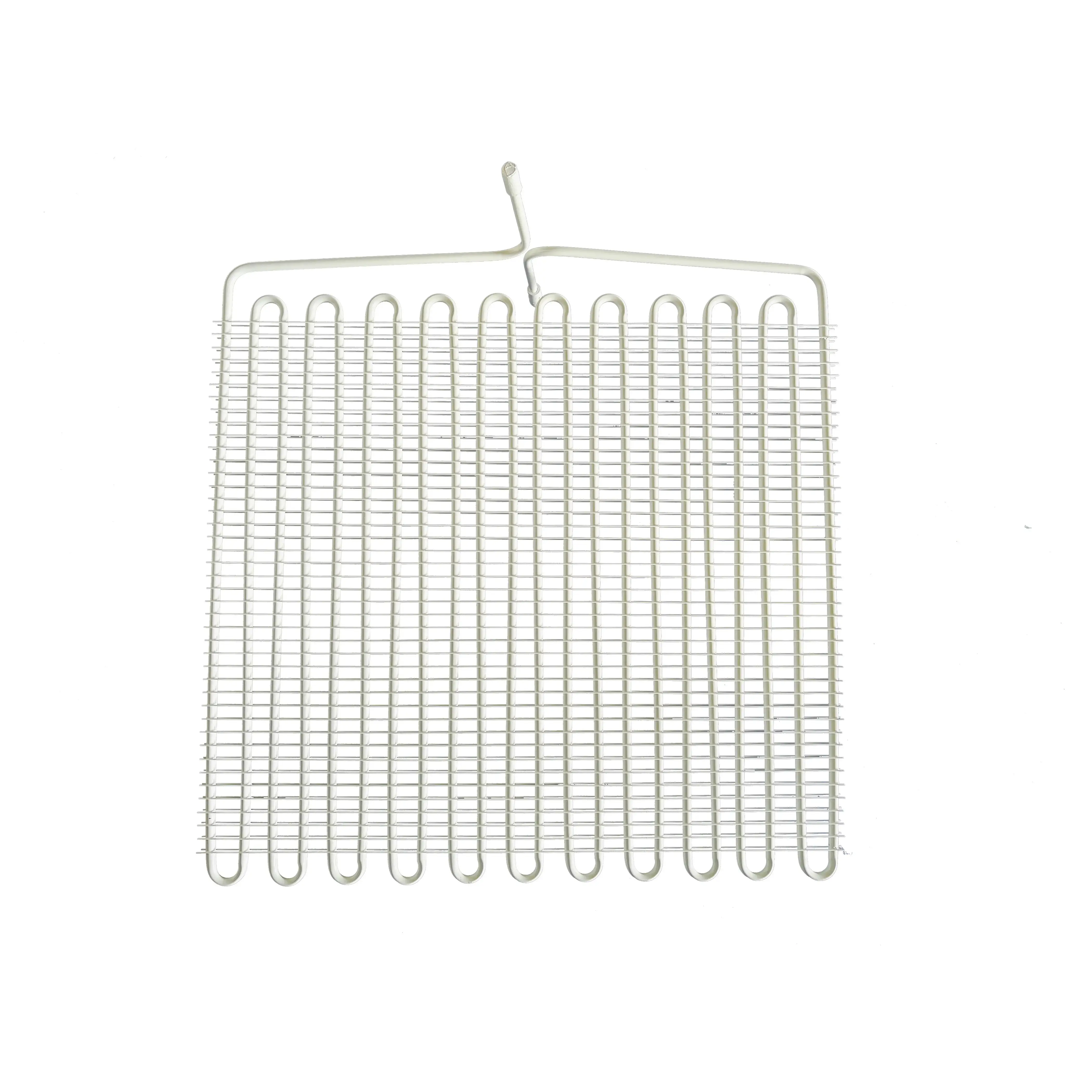

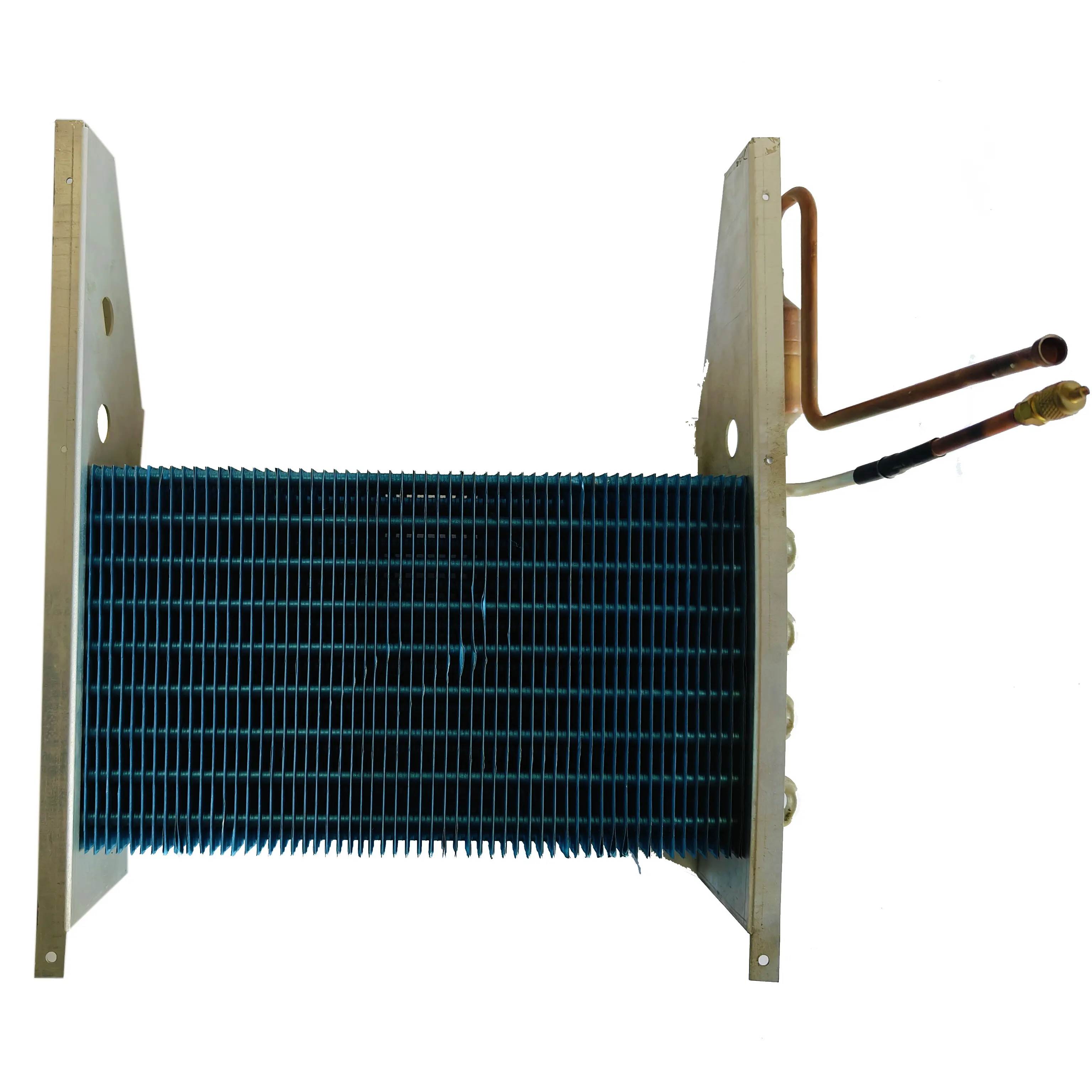

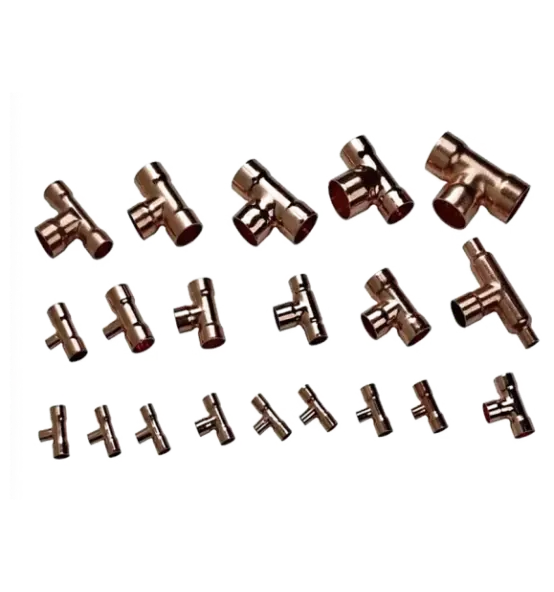

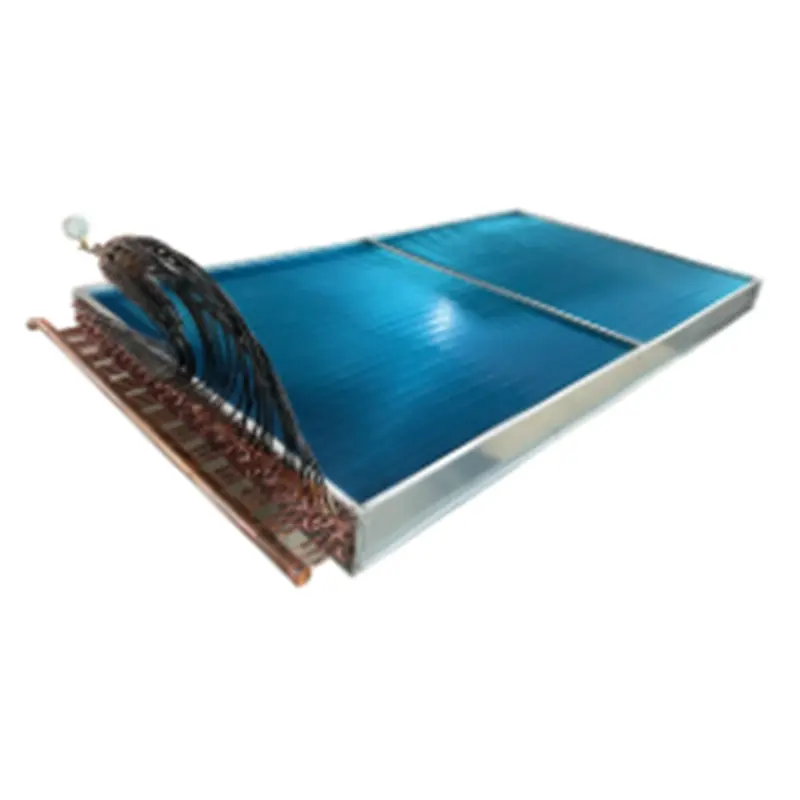

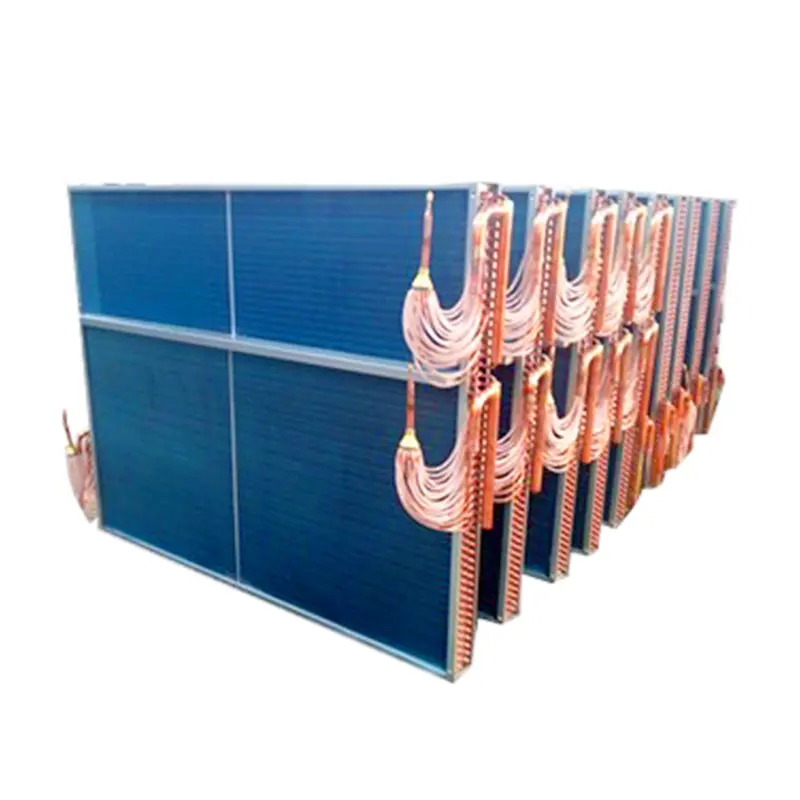

The Shell & Tube Type Evaporator from Ningbo Senjun New Materials Co., Ltd. is engineered for efficiency and durability, making it an essential component in various industrial applications. Designed to optimize thermal exchange, this evaporator utilizes a series of tubes encased in a robust shell, allowing for superior Heat Transfer while minimizing energy consumption. Its modular design facilitates easy cleaning and maintenance, ensuring consistent performance and longevity, Constructed from high-quality materials, the Shell & Tube Type Evaporator is suitable for a wide range of fluids and conditions, making it ideal for chemical processing, food production, and HVAC systems. With customizable options available, this evaporator can be tailored to meet specific operational needs, Ningbo Senjun New Materials Co., Ltd. is committed to providing cutting-edge solutions that enhance productivity and sustainability. The Shell & Tube Type Evaporator embodies this ethos, delivering exceptional reliability and efficiency for industries aiming to improve their thermal management processes

Proven Methods To Shell & Tube Type Evaporator Trusted by Pros From Concept to Delivery

In the dynamic world of industrial cooling solutions, Ningbo Senjun New Materials Co., Ltd. has established itself as a leading player since its inception in 2010. Our commitment to innovation is reflected in our state-of-the-art wire tube condensers and copper aluminum fin heat exchangers, designed to meet the diverse needs of refrigerators, freezers, drinking fountains, and display cabinets. With a focus on continuous research and development, we have honed our techniques to produce highly efficient shell and tube type evaporators that ensure optimal performance and reliability. Our shell and tube type evaporators have been rigorously tested and developed in collaboration with industry professionals, ensuring that they meet the most demanding applications worldwide. Trusted by experts in the field, our methods encompass advanced design principles and materials that maximize heat transfer while minimizing energy consumption. This not only results in superior product performance but also contributes to sustainability goals that are increasingly important in today's market. For global buyers looking for reliable and efficient cooling solutions, partnering with Ningbo Senjun means accessing a wealth of experience and expertise. From concept to delivery, we are dedicated to providing tailored solutions that align with your operational needs, backed by exceptional customer support. Let us help you optimize your cooling processes with our proven innovations, ensuring that your business stays ahead in this competitive landscape.

Proven Methods To Shell & Tube Type Evaporator Trusted by Pros From Concept to Delivery

| Method | Description | Efficiency (%) | Cost (USD) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Thermal Cycling | Using temperature variations to enhance evaporation rates. | 85 | 5000 | 4 |

| Vacuum Evaporation | Reducing pressure to lower boiling point of liquids. | 90 | 8500 | 6 |

| Falling Film Evaporation | Film of liquid flows down vertical tubes for efficient heat transfer. | 92 | 7800 | 8 |

| Forced Circulation | Mechanical pumps facilitate constant liquid movement for effective evaporation. | 88 | 6200 | 5 |

10 tips Shell & Tube Type Evaporator Market Leader From Concept to Delivery

S

Samantha Lee

Fantastic quality! This product exceeded my expectations. The support team was very knowledgeable and addressed all my queries promptly.

08 May 2025

D

Daniel Clark

High-quality product with an impressive finish. The support team was very knowledgeable and addressed my concerns promptly.

16 June 2025

J

Jacob Morgan

Very impressed with this product! The quality is superb and the after-sales service was extremely helpful.

01 June 2025

B

Benjamin Graves

The quality is excellent! The customer service team was friendly and very communicative.

08 June 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025

L

Liam Smith

This product exceeded all my expectations! Outstanding quality and very knowledgeable support team.

12 May 2025