Refrigerant to Water Plate Heat Exchanger Manufacturers in China Factories

As a trusted name in the industry, we specialize in high-quality Refrigerant To Water Plate Heat Exchanger products, perfect for various applications. Our commitment to excellence means you get a reliable solution that enhances efficiency and performance, tailored to meet your specific needs. We are a factory-direct supplier, ensuring that you receive competitive wholesale prices without compromising on quality

Key Methods For Refrigerant To Water Plate Heat Exchanger Manufacturers Your End-to-End Solution Market Leader

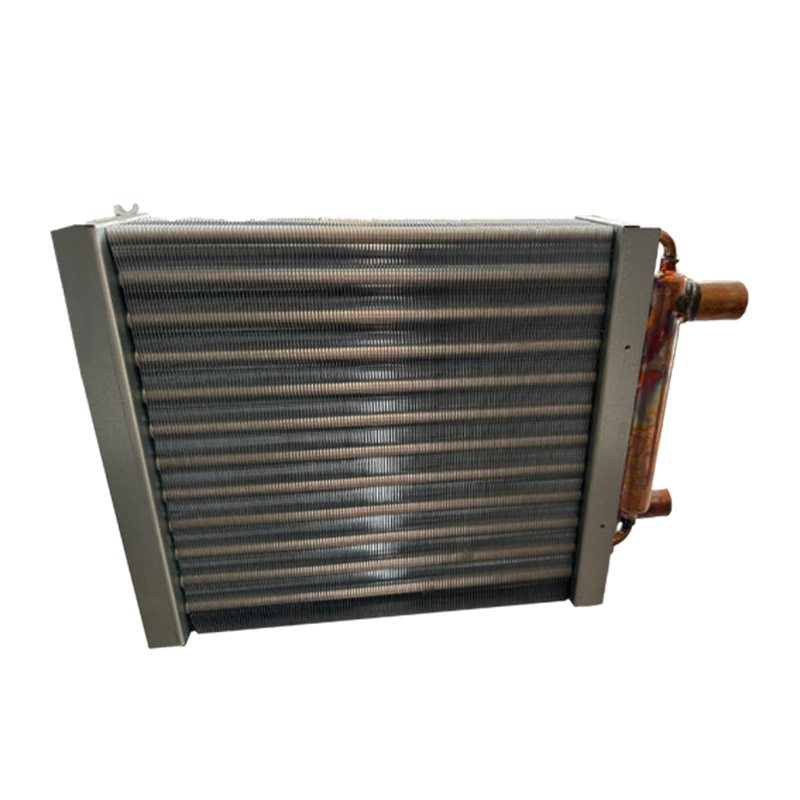

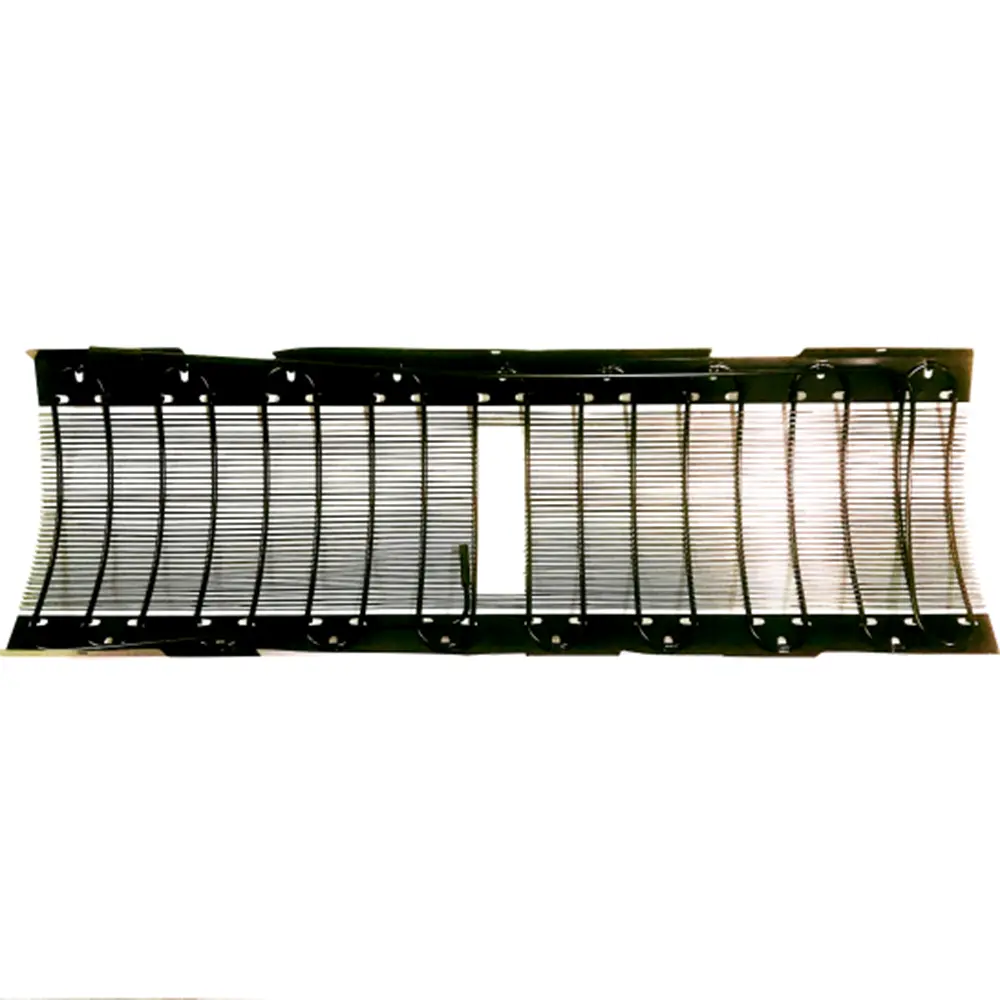

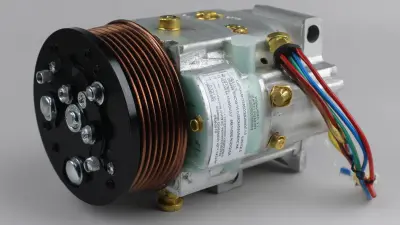

As a leading manufacturer in the heat exchanger industry, Ningbo Senjun New Materials Co., Ltd. stands out for its comprehensive solutions in refrigerant to water plate heat exchangers. Established in 2010, we have dedicated ourselves to the research and development of advanced products including wire tube condensers and copper-aluminum fin heat exchangers tailored for various applications such as refrigerators, freezers, and display cabinets. Our commitment to innovation ensures our clients leverage the most efficient and reliable technology in their cooling systems. One of the key methods we utilize is optimizing the material composition and structure of our heat exchangers to enhance thermal efficiency and reduce energy consumption. By employing high-quality materials and state-of-the-art manufacturing processes, we provide products that not only meet but exceed international quality standards. This approach allows our global partners to achieve superior performance while minimizing operational costs. Moreover, our end-to-end solution framework means we partner closely with our clients, offering technical support, custom designs, and a seamless supply chain experience. As a market leader, we understand the unique challenges faced by businesses worldwide, and we are dedicated to providing tailor-made solutions that fulfill their specific needs. Join us in redefining efficiency and reliability in your cooling systems!

Key Methods For Refrigerant To Water Plate Heat Exchanger Manufacturers: Your End-to-End Solution Market Leader

| Method | Description | Benefits | Application |

|---|---|---|---|

| Plate Design Optimization | Improving the layout and thickness of plates for enhanced heat transfer. | Increased efficiency and lower operational costs. | HVAC systems, refrigeration systems. |

| Turbulent Flow Enhancement | Incorporating features that promote turbulent flow for better heat exchange. | Improved heat transfer rates with reduced footprint. | Industrial cooling and heating applications. |

| Material Selection | Choosing high-conductivity materials for plates and gaskets. | Longer lifespan and superior performance. | Chemical processing, food and beverage cooling. |

| Modular Design | Creating modular units for scalability and maintenance. | Easier upgrades and repairs, reducing downtime. | Data centers, power plants. |

| Computer Simulation | Using simulations to predict performance and optimize designs. | Reduced prototyping costs and improved accuracy. | Research and development, product testing. |

How-To Guide Refrigerant To Water Plate Heat Exchanger Manufacturers Service Backed by Expertise Dominates

J

James Wilson

Exceptional quality! The after-sales service representatives were responsive and educated, making me feel valued.

18 June 2025

A

Abigail Scott

Amazing product! The quality surpassed my expectations, and the support team was incredibly responsive.

25 May 2025

S

Sophia Young

Excellence in both product and service! The after-sales team provided the assistance I needed.

20 May 2025

I

Isabella Williams

High-quality product with helpful and responsive customer service! A truly satisfying experience.

13 May 2025

A

Alexander Johnson

I’m thoroughly impressed with this product! The quality is exceptional, and the support team was top-notch.

06 June 2025

L

Lucas Turner

What a great product! Quality is outstanding, and the customer service was very professional.

06 June 2025