Why Do Medical Ultra-Low Freezers Require Special Heat Exchangers?

I rely on precise cooling to keep medical samples safe. As demand for advanced refrigeration grows—projected to reach$5.63 billion by 2030—specialized systems like the Copper Fin Heat Exchanger become essential. Companies such as senjun lead this field, providing technology that protects sensitive materials from dangerous temperature swings.

Key Takeaways

- Medical ultra-low freezers need special Heat Exchangers because they must keep temperatures extremely low and stable to protect sensitive samples like vaccines and tissues.

- Copper fin heat exchangers work best in these freezers due to copper’s excellent heat transfer, frost prevention design, and reliable performance at ultra-low temperatures.

- Choosing the right heat exchanger saves energy, reduces maintenance costs, and ensures sample safety, making it a smart investment for medical and research facilities.

The Demands of Ultra-Low Temperature Storage

Extreme Temperature Requirements

I work with medical ultra-low freezers that must maintain temperatures far below what standard refrigeration can achieve. These freezers often operate between -40°C and -86°C. For example, the FDA required the Pfizer-BioNTech COVID-19 vaccine to be stored at temperatures between -40°C and -80°C to ensure its stability and effectiveness. Many biological samples, such as cells, tissues, proteins, and mRNA, need this level of cold storage to prevent degradation.

Here is a quick overview of typical temperature ranges:

| Temperature Range (°C) | Application/Description |

|---|---|

| -20°C to -80°C | Pharmaceuticals, biotech, life sciences, healthcare; preserves cells, tissues, proteins, mRNA |

| -40°C to -86°C | Traditional ultra-low freezer range; long-term preservation |

| -80°C | Common target for long-term storage |

I see that even a small temperature fluctuation can damage sensitive samples. Viruses, bacteria, tissue cells, and genetic material are especially vulnerable. Frequent door openings or power issues can cause freeze-thaw cycles, which destroy sample integrity and lead to loss of valuable research data.

Why Standard Heat Exchangers Fall Short

I have learned that not all heat exchangers can handle these extreme demands. Standard models often use materials whose thermal conductivity drops at ultra-low temperatures. For example, nonmetallic materials lose efficiency as temperatures fall, making them less effective at transferring heat. Even metals like stainless steel and carbon steel, while better than nonmetals, do not match the performance of copper or copper/nickel alloys in these conditions.

Common maintenance issues also arise. Fouling from mineral deposits, sediments, or biological growth can block heat transfer surfaces. This leads to temperature deviations and pressure drops, which threaten the stability of stored samples. I know that regular cleaning and careful system design help, but the choice of heat exchanger material remains critical for reliable ultra-low temperature performance.

How Copper Fin Heat Exchanger Technology Meets Ultra-Low Freezer Needs

Design Features for Ultra-Low Temperatures

When I select equipment for ultra-low temperature storage, I look for specific design features that set a Copper Fin Heat Exchanger apart from other options. These features ensure the system can handle the extreme cold and maintain stable performance. The table below highlights the most important aspects:

| Design Feature | Description |

|---|---|

| Material | Copper withstands ultra-low temperatures down to -450°F, making it ideal for extreme cold. |

| Fin Spacing & Configuration | Fins are spaced at 4 fins per inch or less, which prevents frost bridging and maintains heat transfer efficiency. |

| Frost Mitigation | The design uses fin configurations that minimize frost buildup, avoiding intricate surfaces that trap frost. |

| Defrosting Features | Defrost loops with electrical heating elements, glycol solutions, or thermal oils actively combat frost accumulation. |

I have seen that these features allow a Copper Fin Heat Exchanger to operate reliably even when temperatures drop far below freezing. The careful spacing of fins and the use of copper material help prevent common issues like frost bridging, which can quickly reduce efficiency in ultra-cold environments.

Enhanced Efficiency and Reliability

I always prioritize efficiency and reliability in medical freezers. The Copper Fin Heat Exchanger stands out because it uses copper fins and tubes with high-density arrangements. This design increases the surface area available for heat transfer. When I use a system with more surface area, I notice that it moves heat out of the freezer more quickly and evenly. Copper’s excellent thermal conductivity further boosts this effect, ensuring that the freezer maintains a stable, ultra-low temperature.

I have observed that this technology not only improves cooling performance but also reduces the risk of temperature fluctuations. The increased efficiency means the compressor and other refrigeration components do not have to work as hard, which can extend their lifespan. I find that this leads to fewer breakdowns and less maintenance over time.

Tip: Choosing a Copper Fin Heat Exchanger with high-density fins and quality copper materials can make a significant difference in both energy use and sample safety.

Real-World Example: senjun’s Copper Aluminum Fin Heat Exchangers in Medical Freezers

I trust brands that focus on quality and innovation. Ningbo Senjun New Materials Co., Ltd. (senjun) has earned my confidence through its commitment to research, development, and production of advanced heat exchangers. Senjun’s copper aluminum fin heat exchangers play a key role in many medical ultra-low temperature freezers. Here is what I have found when using these products:

- Senjun’s Copper Fin Heat Exchanger uses copper tubes and aluminum fins to maximize heat transfer and withstand extreme cold.

- The company sources high-quality materials and partners with reputable brands for other refrigeration components, ensuring overall system reliability.

- I have noticed that freezers equipped with senjun’s heat exchangers maintain stable temperatures and require less frequent maintenance.

- Senjun’s focus on design and durability means I can trust their products to protect sensitive medical and research samples.

I see that senjun’s dedication to innovation and quality makes their Copper Fin Heat Exchanger a smart choice for any facility that needs dependable ultra-low temperature storage.

Risks and Benefits of Choosing the Right Heat Exchanger

Risks of Using Inadequate Heat Exchangers

When I choose the wrong heat exchanger for a medical ultra-low freezer, I put both my equipment and valuable samples at risk. I have seen several problems arise from inadequate heat exchangers:

- Increased compressor stress often leads to unexpected failures and costly repairs.

- Oil logging can block refrigerant flow, causing the freezer to warm up and require repeated service.

- Equipment downtime disrupts my lab’s workflow and reduces productivity.

- Temperature excursions threaten the integrity of irreplaceable clinical or research samples.

- Service calls for compressor replacement, calibration, and refrigerant costs can quickly add up to thousands of dollars.

I always make sure to follow best practices like regular cleaning of condenser coils, inspecting door gaskets, and monitoring temperatures. These steps help maintain reliability, but the right heat exchanger remains the foundation for consistent performance.

Benefits of Using the Right Equipment

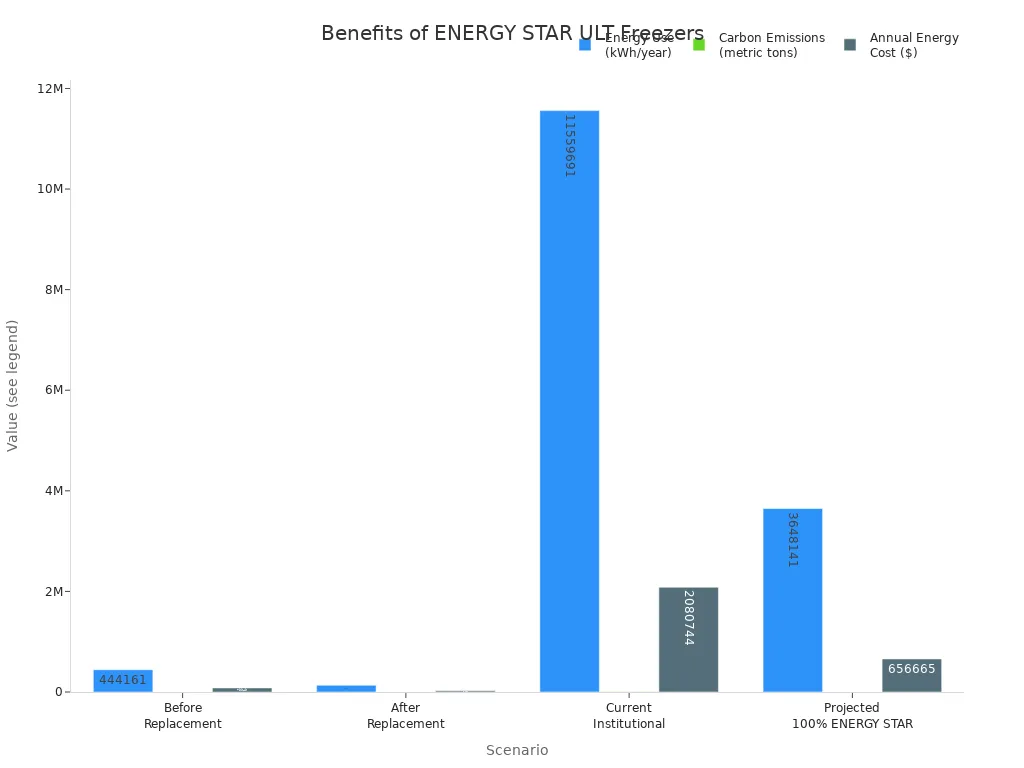

I have found that investing in the correct heat exchanger technology, such as those developed by senjun, brings measurable benefits to my facility. The data below highlights the impact:

| Metric | Before Replacement (Conventional ULT) | After Replacement (ENERGY STAR ULT) | Net Savings / Reduction | Percentage Reduction |

|---|---|---|---|---|

| Energy Use (kWh/year) | 444,161 | 133,667 | 310,493 | 70% |

| Carbon Emissions (metric tons) | 192 | 58 | 134 | 70% |

| Annual Energy Cost ($) | 79,949 | 24,060 | 55,889 | 70% |

I have seen similar results at the institutional level, with energy use and costs dropping by nearly 70%. The pilot project at UCSF demonstrated an 8-year payback period, making the investment worthwhile. My facility now enjoys lower maintenance costs, fewer breakdowns, and a reduced carbon footprint.

Choosing the right heat exchanger not only protects my samples but also saves money and supports sustainability goals.

I always choose special heat exchangers for my medical ultra-low freezers. Copper Fin Heat Exchanger technology keeps my samples safe and my operations efficient.

- Advanced systems lower energy demand and maintenance costs.

- Smart controls and resilient designs improve reliability and reduce downtime.

I trust senjun for dependable performance and long-term savings.

FAQ

What makes copper fin heat exchangers better for ultra-low freezers?

I choose copper fin heat exchangers because copper transfers heat quickly. This keeps my freezer cold and stable. I trust this technology for sensitive medical samples.

How often should I maintain my ultra-low freezer’s heat exchanger?

I check and clean my heat exchanger every three months. Regular maintenance prevents frost buildup and ensures reliable performance.

Tip: Schedule reminders for routine checks.

Can I retrofit my existing freezer with a senjun copper aluminum fin heat exchanger?

Yes, I can upgrade many freezers with senjun’s copper aluminum fin heat exchanger. I recommend consulting a technician for compatibility and installation advice.