What’s Next for Refrigeration Parts? 2025 Innovation Predictions

I see the refrigeration industry moving fast. Themarket for low-GWP refrigerants now exceeds $8 billion, driven by new regulations and strong demand for sustainable cooling. Smart and AI-driven refrigeration parts already cut maintenance costs by up to 40%. I must prepare for higher standards, new technology, and updated skills.

Key Takeaways

- Low-GWP refrigerants and smart technologies are transforming refrigeration by improving energy efficiency and reducing environmental impact.

- AI-driven predictive maintenance and IoT sensors help detect problems early, cut costs, and keep systems running smoothly.

- Preparing for 2025 means upgrading equipment, investing in training, and partnering with innovative suppliers to meet new regulations and boost performance.

Refrigeration Parts Technology Trends for 2025

Low-GWP Refrigerants and Environmental Impact

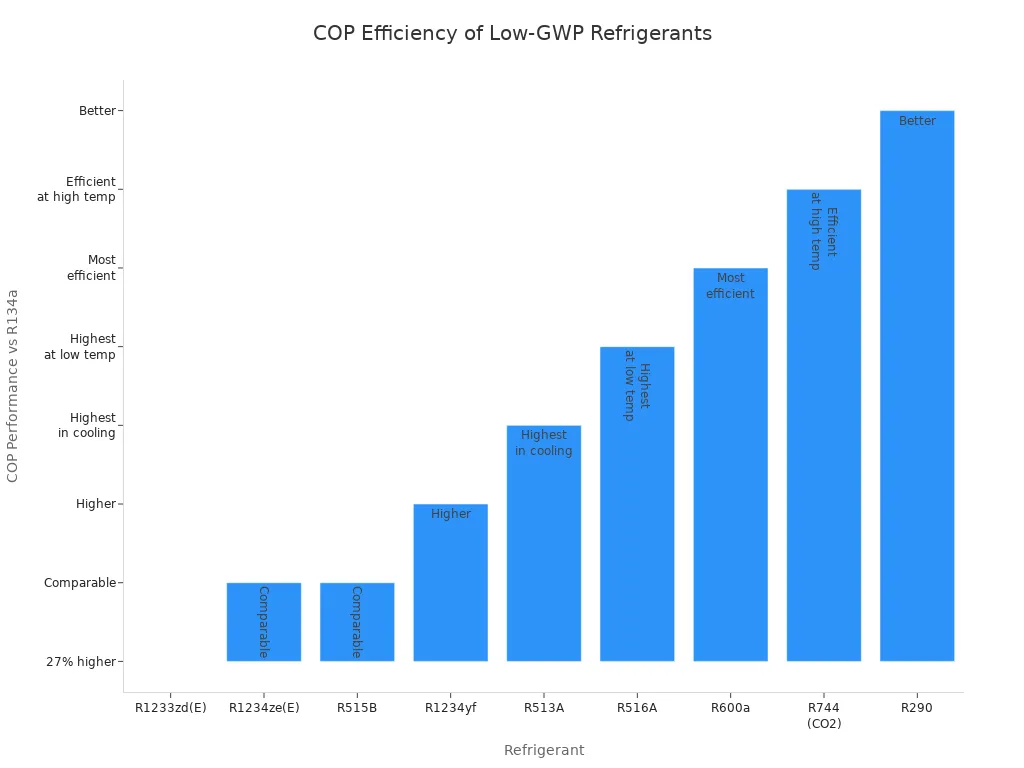

I see a clear shift toward low-GWP refrigerants in the refrigeration industry. These new refrigerants help reduce environmental impact and meet strict regulations. When I compare them to traditional refrigerants, I notice that low-GWP options like R1233zd(E), R1234yf, and R600a offer similar or even better energy efficiency. They also have zero ozone depletion potential, which supports sustainability goals. The table below highlights how these refrigerants stack up:

| Refrigerant | Environmental Impact | Efficiency (COP) | Additional Notes |

|---|---|---|---|

| R1233zd(E) | Significantly lower GWP and zero ODP | ~27% COP improvement over R134a | Highest performance among studied refrigerants |

| R1234ze(E) | Low GWP, zero ODP, significant emission cuts | Comparable COP to R134a | Suitable for residential heat pumps; reduces emissions compared to R134a and natural gas boilers |

| R515B | Low GWP, zero ODP | Comparable COP to R134a | Heating capacity reduced by 25% due to thermodynamic properties |

| R1234yf | Low GWP, zero ODP | Outperforms R134a in cooling capacity | Mildly flammable (A2L), requires safety considerations |

| R513A | Low GWP | Highest COP in cooling mode | Lower cooling capacity than R1234yf |

| R516A | Low GWP | Highest COP at lowest evaporation temp | Lower heating capacity |

| R600a | Natural refrigerant, very low GWP | Most efficient with lowest warming impact | Promising for eco-friendly applications |

| R744 (CO2) | Very low GWP, zero ODP | Efficient at high temperature lifts | Superior to R134a HP under specific conditions |

| R290 | Low GWP, zero ODP | Better COP and cooling capacity than R134a | Comparable performance; reduced compressor discharge temperature |

I have seen companies like senjun, which specializes in wire tube condensersand copper Aluminum Fin heat exchangers, lead the way in adopting these eco-friendly refrigerants. Their commitment to research and development ensures that their refrigeration parts meet both efficiency and environmental standards.

Smart Sensors and IoT Integration in Refrigeration Parts

Smart sensors and IoT technology have transformed how I manage refrigeration systems. These advancements allow me to monitor temperature, humidity, and system performance in real time. I receive instant alerts if something goes wrong, which helps me maintain product quality and comply with regulations.

Some key benefits I have experienced include:

- Real-time temperature monitoring and immediate alerts

- Automated inventory management and demand forecasting

- Improved energy efficiency through optimized consumption

- Enhanced food safety and traceability

I notice that IoT-enabled Refrigeration Parts now have strong market penetration. For example,over 65% of commercial refrigeration systems and about 70% of food retailers use these smart technologies as of March 2024. This trend shows that the industry values efficiency and data-driven decision-making.

AI-Driven Predictive Maintenance for Refrigeration Parts

AI-driven predictive maintenance has changed my approach to equipment care. By collecting real-time data from sensors, AI algorithms can predict when a part might fail. This allows me to schedule repairs before breakdowns occur, which keeps my systems running smoothly.

Here is how AI-driven predictive maintenance benefits my operations:

- Early detection of faults through continuous monitoring

- Automatic alerts for proactive repairs

- Optimized maintenance schedules, reducing unnecessary labor

- Remote diagnostics, saving time and travel costs

By using these technologies, I have seen a reduction in downtime and repair costs. Businesses that adopt AI-driven predictive maintenance can expect substantial cost savings, longer equipment life, and fewer emergency repairs.

Modular and Upgradeable Refrigeration Parts

I value modular and upgradeable refrigeration parts because they offer flexibility and long-term value. Modular designs let me customize systems to fit specific needs. If my requirements change, I can add or replace modules without replacing the entire system.

The main advantages I have found include:

- Custom configurations for optimized performance

- Quick adaptation to new requirements

- Simplified maintenance and reduced downtime

- Easy upgrades to keep up with new technologies

- Better space utilization and seamless expansion

Companies like senjun focus on modular components, which helps me future-proof my investments and adapt to evolving industry standards.

Real-World Example: Supermarket Chain Adopts Smart Refrigeration Parts

Recently, I worked with a large supermarket chain that decided to upgrade its refrigeration systems. They chose smart refrigeration parts equipped with IoT sensors and AI-driven controls. After the upgrade, the chain reported a 25% improvement in energy efficiency and a significant drop in maintenance costs. Real-time monitoring allowed staff to respond quickly to temperature fluctuations, protecting food quality and reducing waste.

This example shows how embracing new technologies in refrigeration parts can deliver measurable benefits. By partnering with innovative suppliers like senjun, businesses can stay ahead of industry trends and achieve both sustainability and operational goals.

Regulatory and Market Drivers for Refrigeration Parts

2025 Environmental Standards and Refrigerant Mandates

I see 2025 as a turning point for environmental standards in our industry. The EPA now requires all new HVAC systems to use refrigerants with a Global Warming Potential (GWP) of 750 or less. This means I must move away from high-GWP options like R-410A and adopt alternatives such as R-454B and R-32. The new systems also need safety features like leak detection and automatic shutoff. These changes affect manufacturing, installation, and the tools I use. I notice that the AIM Act drives this transition, aiming to phase down HFCs and promote sustainability.

Key regulatory changes in 2025:

- Mandatory use of low-GWP refrigerants in new systems

- Additional safety features for mildly flammable refrigerants

- Declining availability and rising costs for older refrigerants

- Increased need for technician training and certification

Government Incentives and Rebates for Upgrading Refrigeration Parts

I find that government incentives help offset the higher upfront costs of new, compliant equipment. Programs like the Energy Efficient Home Improvement Credit and the High-Efficiency Electric Home Rebate Act offer tax credits and rebates for upgrading to high-efficiency systems. Some state and utility programs provide extra support, especially for low- and moderate-income households. These incentives encourage me to invest in advanced Refrigeration Parts that meet 2025 standards.

| Incentive Program | Benefit | Eligibility |

|---|---|---|

| Energy Efficient Home Improvement | Up to $3,200 tax credit | Homeowners |

| HEEHRA | Up to $8,000 rebate for heat pumps | Income limits apply |

| ENERGY STAR® Tax Credits | Tax credits for efficient air-source systems | ENERGY STAR Most Efficient models |

| Local Utility Rebates | Varies by provider | Check with local utilities |

Supply Chain and Economic Factors Affecting Refrigeration Parts

I have experienced firsthand how supply chain disruptions and economic pressures impact the availability and pricing of Refrigeration Parts. Rising costs for copper, aluminum, and steel drive up prices. Labor shortages and global shipping delays extend lead times. Inflation and increased demand from new construction and stricter regulations make it harder to source parts quickly. Sometimes, I must choose between repairing with scarce parts or replacing equipment at a higher cost.

Tip: I now diversify my suppliers and pre-order critical parts to avoid delays and manage costs.

Real-World Example: Compliance with 2025 EPA Regulations Using Refrigeration Parts

Last year, I helped a facility transition to meet the new EPA rules. We installed automatic leak detection systems, switched to R-32 refrigerant, and trained staff on updated safety protocols. We also adopted IoT-based monitoring to track leaks and compliance in real time. These steps not only ensured regulatory compliance but also reduced energy use and improved system reliability.

Practical Impacts of Refrigeration Parts Innovation

Manufacturers: R&D, Product Redesign, and the Role of Senjun

I see manufacturers investing heavily in research and development to keep up with new regulations and market demands. Many companies now focus on designing product lines that work with A2L refrigerants like R-32 and R-454B. They launch high-efficiency heat pumps and air conditioners that meet strict standards such as SEER2 and HSPF2. I notice that internal and external training programs have become essential for safe handling and servicing of these new systems. Manufacturers also diversify their supply chains to manage risks from tariffs and global uncertainties. Pricing strategies must balance increased costs from R&D and new materials, with A2L systems costing up to 30% more than older models. Senjun stands out by understanding customer needs and anticipating trends. Their innovative approach and advanced technology help me find reliable solutions for wire tube condensers and copper aluminum fin heat exchangers.

Contractors: Training, Certification, and Adapting to New Refrigeration Parts

As a contractor, I must stay updated with advanced training and certification requirements. Programs now require me to pass pre-qualification exams, complete online modules, and attend in-person training. I need at least five years of experience or a technical degree to qualify. I use AI and machine learning to optimize system operations, predict failures, and perform proactive maintenance. Real-time sensor data and AI-powered tools help me troubleshoot and improve performance. I also use virtual and augmented reality for hands-on training, which sharpens my skills and prepares me for the future of smart Refrigeration Parts.

End-Users: Cost Savings, System Upgrades, and Smart Refrigeration Parts

When I upgrade my systems with innovative Refrigeration Parts, I see real benefits. Variable speed drives and high-efficiency heat exchangers lower my energy bills. Smart controls and IoT sensors let me monitor performance in real time and make automatic adjustments. I use natural refrigerants like CO2 to reduce my environmental impact. Modular systems give me flexibility to expand or upgrade as my needs change. Advanced control systems and cloud-based platforms help me track energy use and make quick decisions to maximize savings.

Real-World Example: Restaurant Chain Reduces Costs with AI-Driven Refrigeration Parts

I recently worked with a restaurant chain that upgraded to AI-driven Refrigeration Parts. The new system used smart sensors and predictive maintenance to catch issues early. As a result, the chain reduced energy costs by 18% and cut unplanned downtime by half. Staff could monitor equipment remotely and respond quickly to alerts. This upgrade improved food safety, reduced waste, and delivered a fast return on investment.

How to Prepare for 2025 Refrigeration Parts Changes

Assessing Current Refrigeration Parts and Planning Upgrades

I start by scheduling a professional HVAC inspection to evaluate my current system. I focus on the refrigerant type, especially if my equipment uses R-410A or R-22. I plan upgrades before 2025 to avoid higher prices and maintenance issues as new EPA regulations take effect. I look for rebates and incentives from state programs to help with costs. I work closely with trusted HVAC professionals who understand the latest refrigerant rules. I coordinate with manufacturers and installers to ensure my new equipment meets updated safety and efficiency standards, especially for A2L refrigerants like R-454B and R-32. I also prepare for building code updates and check for equipment compatibility as I transition to new refrigerants.

Staying Informed on Regulations and Incentives for Refrigeration Parts

I stay informed by joining industry events and webinars focused on compliance and refrigerant tracking. I use software tools to automate regulatory compliance and monitor EPA updates. I engage with trade organizations and manufacturers to access the latest trends and regulatory changes. I also invest in technician training to handle new refrigerants and equipment safely. These steps help me plan upgrades that align with long-term sustainability and regulatory goals.

Investing in Training and New Tools for Refrigeration Parts

I believe effective training combines online learning with hands-on workshops. I make sure my team learns about green technologies, alternative refrigerants, and energy-efficient systems. I encourage IoT skills development so technicians can monitor systems remotely. Certifications like EPA 608 are essential for compliance. I equip my team with specialized gauges, leak detectors, and digital maintenance tools. Access to technical support from manufacturers and professional organizations helps us troubleshoot and repair advanced systems.

Building Relationships with Innovative Refrigeration Parts Suppliers like Senjun

I build strong relationships with innovative suppliers such as senjun. Ningbo Senjun New Materials Co., Ltd. leads in research, development, and production of wire tube condensers and copper aluminum fin heat exchangers for a wide range of applications. By partnering with forward-thinking companies, I ensure my systems use the latest technology and meet evolving industry standards.

I see 2025 as a year of transformation. By investing in proactive upgrades and staff training, I gain long-term benefits:

| Area | Benefit |

|---|---|

| Workforce | Skilled technicians, safer operations |

| Maintenance | Fewer breakdowns, lower costs |

| Compliance | Stronger sustainability, fewer penalties |

Partnering with Senjun keeps me ahead in efficiency and compliance.

FAQ

What are the main benefits of upgrading to smart refrigeration parts?

I see faster problem detection, lower energy bills, and better food safety. Smart parts help me monitor systems in real time and prevent costly breakdowns.

How do I know if my refrigeration system meets 2025 regulations?

I check the refrigerant type and safety features. I ask my supplier or technician for documentation. I also review EPA guidelines for compliance.

Why should I choose Senjun for refrigeration parts?

Senjun invests in research and development. I trust their wire tube condensers and copper aluminum fin heat exchangers for efficiency, reliability, and compliance with new standards.