Top 3 Maintenance Mistakes for Refrigeration Heat Exchangers

I often see costly failures in refrigeration systems when users overlook simple maintenance steps. Insufficient cleaning, wrong materials, or ignoring key parameters in aCopper Fin Heat Exchanger can cause inefficiency or downtime. I believe that understanding these mistakes helps me keep equipment reliable and running at peak performance.

Key Takeaways

- Regular cleaning of Copper Fin Heat Exchangers prevents dust buildup that blocks airflow and reduces efficiency, helping systems run smoothly and last longer.

- Always use the correct materials and parts specified by manufacturers to avoid corrosion, leaks, and costly repairs in Heat Exchangers.

- Monitor pressure drop and system parameters closely to detect issues early, maintain optimal performance, and prevent equipment failures.

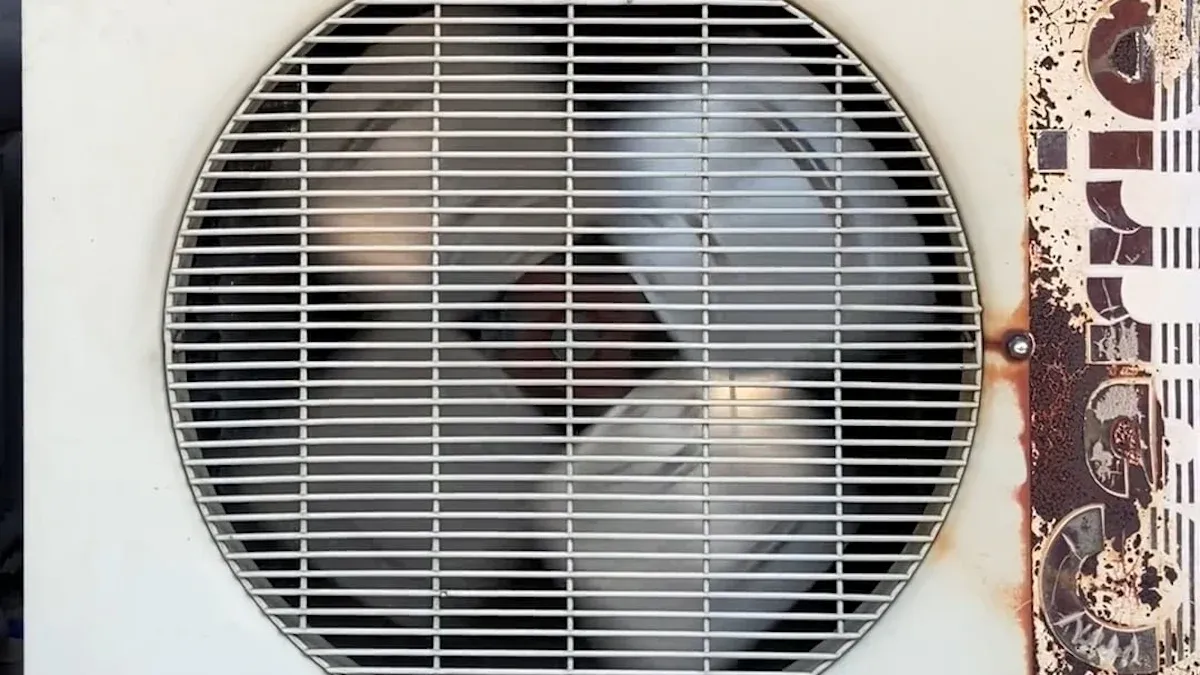

Insufficient Cleaning and Maintenance

Why Regular Cleaning Matters for Copper Fin Heat Exchangers

I always prioritize regular cleaning for every Copper Fin Heat ExchangerI maintain. Dust, dirt, and debris quickly accumulate on the fins and coils, especially in environments with poor accessibility. This buildup blocks airflow and reduces Heat Transfer efficiency. I have seen how even a thin layer of dust can cause a noticeable drop in performance. Regular cleaning removes these deposits and keeps the system running at optimal efficiency. Scheduled inspections and cleaning routines tailored to the specific fouling types—like scaling or biological growth—help me prevent efficiency loss and extend equipment life.

| Maintenance Issue | Cause(s) of Issue | Effect on Refrigeration Heat Exchangers and HVAC Systems |

|---|---|---|

| Dust buildup and blocked fins | Poor accessibility for cleaning | Reduced airflow, blocked fins, decreased heat exchanger efficiency |

| Buildup or dust on coils | Insufficient or lack of cleaning | Airflow obstruction, system performance degradation |

| Leakage from coils (fins) | Dust accumulation and poor maintenance | Coil leakage, potential corrosion, and system damage |

| Corrosion/scaling of cooling coils | Inadequate coil selection, moisture | Mineral deposits, leaks, and coil degradation |

| Water leakage | Poor condensate pan material, dust blockages | Leakage issues affecting system reliability |

| Maintenance accessibility issues | Crowded layouts, improper access panels | Difficulty in cleaning, dirt accumulation, maintenance defects |

Consequences of Neglecting Cleaning

When I neglect cleaning, I see a rapid decline in system performance. Fouling on the Copper Fin Heat Exchanger surfaces leads to higher energy consumption and increased operating costs. Over time, dust and debris can cause coil leakage, corrosion, and even water damage. These issues not only reduce efficiency but also shorten the lifespan of the equipment.

How to Avoid Insufficient Maintenance

To avoid these problems, I follow proven maintenance strategies:

- I use Reliability-Centered Maintenance to target critical components.

- I prioritize high-risk equipment with Risk-Based Maintenance.

- I rely on Condition-Based Maintenance, using sensor data to schedule cleaning and repairs.

- I perform regular Preventive Maintenance to catch issues early.

- I balance corrective actions with proactive care to minimize downtime.

These approaches help me optimize maintenance intervals and keep the system reliable.

Real-World Example: Blocked Fins Causing System Failure

Last year, I inspected a refrigeration unit that had stopped cooling. I found the Copper Fin Heat Exchanger completely blocked by dust and debris. Airflow had dropped so much that the compressor overheated and failed. After a thorough cleaning and component replacement, the system returned to normal operation. This experience reinforced my commitment to regular cleaning and maintenance.

Using Incorrect Materials or Components

Common Errors with Copper Fin Heat Exchanger Parts

I often see technicians select replacement parts without checking for compatibility. They might use generic fittings or substitute metals that look similar but have different properties. Sometimes, I notice that people use fasteners or gaskets not designed for refrigeration systems. These mistakes seem minor at first, but they can cause big problems later.

Risks of Incompatible Materials and Components

When I use the wrong materials in a Copper Fin Heat Exchanger, I increase the risk of failure. For example, improper coatings or mismatched metals can lead to corrosion or leaks. I have read studies showing that incorrect materials or poor processing, such as uneven copper surfaces or faulty coatings, can cause defects. These defects may not show up right away, but over time, they weaken the system and reduce reliability. Even a small change in material can affect how the heat exchanger handles pressure and temperature.

Tip: Always check the manufacturer’s specifications before replacing any part in a Copper Fin Heat Exchanger.

Steps to Ensure Proper Replacement and Compatibility

I follow a simple checklist to avoid mistakes:

- I verify the material and part number before ordering replacements.

- I consult technical manuals or contact the manufacturer if I am unsure.

- I inspect new parts for quality and compatibility before installation.

- I keep records of all replacements for future reference.

This process helps me maintain system integrity and avoid costly repairs.

Real-World Example: Corrosion from Wrong Material Choice

Last year, I worked on a display cabinet that had frequent leaks. I discovered that a previous repair used a non-compatible metal fitting in the Copper Fin Heat Exchanger. The different metals reacted and caused rapid corrosion. After replacing the fitting with the correct material, the leaks stopped, and the system ran smoothly.

Ignoring Pressure Drop and System Parameters

Understanding Pressure Drop in Copper Fin Heat Exchangers

I always pay close attention to pressure drop when I work with a Copper Fin Heat Exchanger. Pressure drop refers to the loss of pressure as refrigerant flows through the heat exchanger. Several factors influence this, such as surface roughness, chevron angle, and the type of coating used. For example:

- Copper-coated gasket plate heat exchangers can show a 1.25 times higher pressure drop than plain ones.

- Surface roughness may increase up to 35 times after copper spray coating, which boosts both the Reynolds number and heat transfer.

- The Nusselt number and friction factor can rise by 1.5 to 2 times as the Reynolds number increases.

These changes can improve heat transfer, but they also make it essential to monitor pressure drop closely.

Impact of Ignoring System Parameters

When I ignore system parameters, I see a direct hit to performance. Cooling capacity, system power, and the coefficient of performance (COP) all suffer. Studies show that faults like heat exchanger fouling can reduce cooling capacity by up to 80.5% and decrease system power by as much as 71%. These numbers highlight how neglecting system parameters leads to wasted energy and poor efficiency.

Monitoring and Adjusting for Optimal Performance

I use regular monitoring to keep my systems running smoothly. I check pressure gauges, temperature sensors, and flow meters to spot any abnormal readings. If I notice a sudden rise in pressure drop, I investigate for blockages or fouling. I also adjust system settings to maintain optimal flow and temperature. This proactive approach helps me prevent costly breakdowns and ensures reliable operation.

Tip: Always compare current system data with baseline performance to catch issues early.

Real-World Example: Compressor Damage from Overlooked Pressure Drop

I once managed a refrigeration system where the compressor failed unexpectedly. After a detailed inspection, I found that a clogged Copper Fin Heat Exchanger had caused a significant pressure drop. The compressor had to work harder, leading to overheating and eventual failure. This experience taught me the importance of monitoring pressure drop and system parameters at all times.

About senjun and Our Expertise

Company Overview: Ningbo Senjun New Materials Co., Ltd.

I work at Ningbo Senjun New Materials Co., Ltd., a company that focuses on innovation and reliability in the refrigeration industry. My team and I dedicate ourselves to the research, development, and production of high-quality heat exchangers and condensers. We supply products for a wide range of applications, including refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, medical ultra-low temperature refrigerators, ice makers, and dehumidifiers. Every day, I see how our commitment to excellence helps our clients achieve better performance and longer equipment life.

At senjun, I believe that strong technical support and continuous improvement set us apart in the market.

Our Commitment to Quality in Copper Aluminum Fin Heat Exchangers

I take pride in our strict quality control processes. My colleagues and I inspect every Copper Fin Heat Exchanger and copper aluminum fin heat exchanger before it leaves our facility. We use advanced testing equipment to ensure each product meets industry standards for durability and efficiency. I also work closely with our R&D team to develop new solutions that address the changing needs of our customers. When I recommend a senjun product, I know it will deliver reliable performance and energy savings.

- I always listen to customer feedback.

- I focus on long-term partnerships.

- I strive to provide technical guidance and after-sales support.

I see how insufficient cleaning, using the wrong materials, and ignoring system parameters can cause costly failures. I recommend reviewing maintenance routines and adopting proactive strategies.

- Smart sensors and predictive analytics help reduce downtime.

- Routine inspections and easy-to-clean designs support reliability.

- Proactive maintenance lowers costs and improves performance.

FAQ

How often should I clean my copper fin heat exchanger?

I recommend cleaning every three to six months.

Tip: Increase cleaning frequency if your environment is dusty or humid.

What materials should I avoid when replacing parts?

I never use non-refrigeration metals or generic gaskets.

- Always check compatibility with manufacturer specifications.

How can I monitor pressure drop effectively?

I use digital gauges and compare readings to baseline data.

Regular monitoring helps me catch problems before they cause damage.