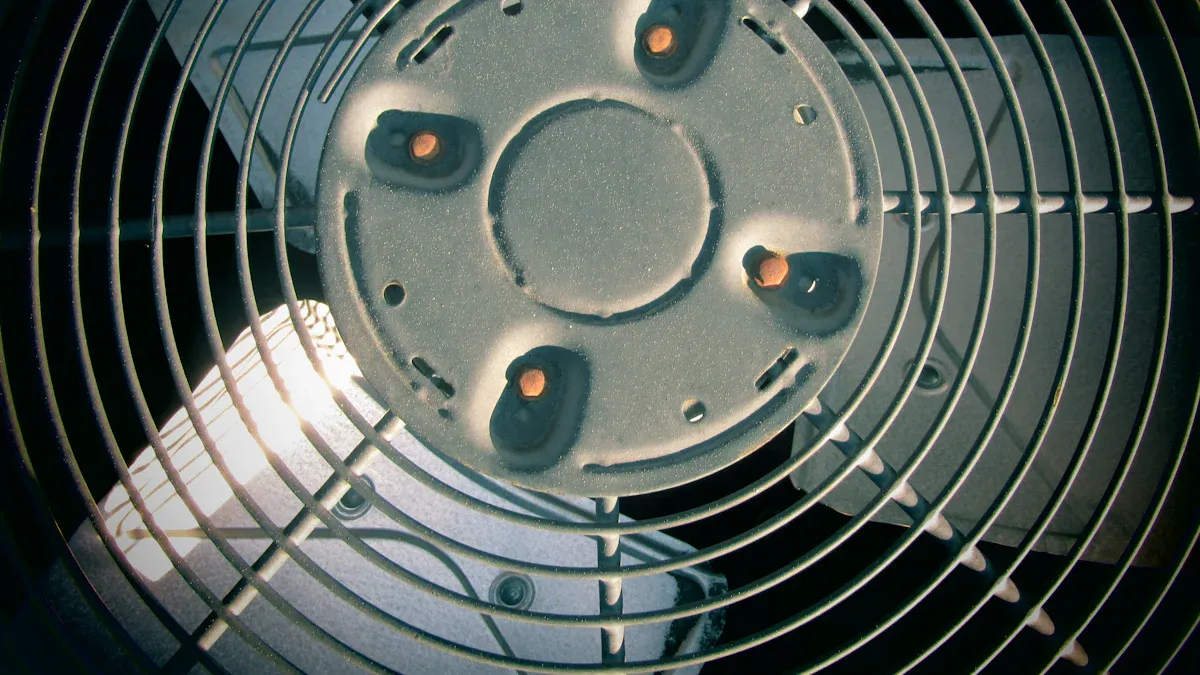

How to Pass EU CE Certification for Export Condensers?

When I export a wire tube condenser to the EU, I focus on CE certification to avoid serious issues. Non-compliance can bring penalties, product recalls, or blocked market access. At senjun, I ensure every step meets strict EU requirements, protecting both my business and reputation.

Key Takeaways

- CE certification proves your export condensers meet strict EU safety and environmental rules, allowing legal sales in Europe and building customer trust.

- Follow a clear process: identify relevant EU rules, conduct risk assessments and product tests, prepare detailed documents, work with a Notified Body if needed, and properly mark your product with the CE label.

- Maintain compliance after certification by updating documents, monitoring rule changes, and performing regular audits to keep your products ready for the EU market.

CE Certification Requirements for Wire Tube Condenser Exporters

What CE Certification Means for Export Condensers

When I export a wire tube condenser to the EU, I must ensure it carries the CE mark. This mark is more than just a label. It shows that my product meets strict European health, safety, and environmental protection standards. As a manufacturer at senjun, I use the CE marking to declare that my Wire Tube Condensers conform to all essential EU regulatory requirements. This step allows me to legally market and sell my products throughout the European Economic Area. The CE mark also reassures my customers that I prioritize quality and safety.

Key EU Directives and Standards for Wire Tube Condensers

I always start by identifying the main EU directives and harmonized standards that apply to my wire tube condenser products. The Pressure Equipment Directive (PED) is especially important for pressurized equipment. I also pay close attention to standards such as EN 378 and ISO 5149, which set requirements for safety and environmental impact. By following these rules, I make sure my products meet all technical and legal expectations for the EU market.

Tip: I keep detailed technical documentation, including product descriptions, design details, test reports, and risk assessments. This documentation proves my compliance during inspections or audits.

Why CE Certification Is Mandatory for EU Market Access

- CE certification ensures my wire tube condenser meets EU safety, health, and environmental standards.

- It demonstrates that I comply with directives like the PED.

- The process requires risk assessment, product testing, and technical documentation.

- For higher-risk products, I work with a Notified Body for third-party assessment.

- The CE mark is essential for legal entry into the EU market and helps build customer trust.

- Proper documentation and marking prevent penalties, shipment delays, or recalls.

- CE certification supports EU goals for environmental protection and product safety.

Step-by-Step Process to Pass CE Certification

Identify Relevant Directives and Standards

When I begin the CE certification process for a wire tube condenser, I always start by identifying the EU directives and standards that apply to my product. I review documents like the Pressure Equipment Directive (2014/68/EU) and the RoHS Directive, which restricts hazardous substances. I also check for any specific requirements related to the materials used, such as stainless steel tubing. Because the information is often spread across different sources, I consult multiple documents and, when necessary, seek advice from compliance experts. This approach ensures I do not overlook any important regulation that could affect my wire tube condenser’s market access.

Tip: I keep a checklist of all directives and standards I identify. This helps me stay organized and ensures I address every requirement during the certification process.

Product Testing and Risk Assessment Procedures

After identifying the relevant directives, I move on to product testing and risk assessment. I conduct a thorough risk assessment to identify any hazards associated with my wire tube condenser. I use guidelines from organizations like CENELEC, which provide practical templates and scoring systems for evaluating risks. This process helps me determine which essential requirements and harmonized standards I need to follow to reduce or eliminate risks.

- I examine potential hazards, such as electrical safety or pressure-related risks.

- I use both internal and external laboratory testing to verify that my wire tube condenser meets all safety and performance standards.

- I document every step of the risk assessment, including the methods and results.

This careful approach ensures my product not only meets legal requirements but also delivers reliable performance to my customers.

Preparing Technical Documentation and Declaration of Conformity

Once I complete testing and risk assessment, I prepare the technical documentation. This file includes detailed product descriptions, design drawings, test reports, and risk assessments. I make sure every document clearly demonstrates how my wire tube condenser complies with EU regulations.

Next, I draft the Declaration of Conformity. In this document, I formally state that my product meets all applicable EU requirements. I sign and date the declaration, then keep it on file for at least ten years. This step is crucial because authorities may request to see this documentation at any time.

Working with a Notified Body for Wire Tube Condensers

For certain wire tube condenser models, especially those considered higher risk, I work with a Notified Body. This independent organization reviews my product and documentation to confirm compliance with EU directives. The Notified Body may conduct additional testing or audits. Their assessment provides an extra layer of assurance that my wire tube condenser meets all safety and quality standards.

Note: Not every product requires Notified Body involvement. I always check the specific requirements for my wire tube condenser before starting this step.

Affixing the CE Mark and Post-Certification Obligations

After completing all assessments and documentation, I affix the CE mark to my wire tube condenser. I make sure the mark is visible, legible, and permanent. This symbol shows that my product meets all EU requirements and can be sold throughout the European Economic Area.

My responsibilities do not end after affixing the CE mark. I maintain compliance by:

- Conducting regular internal and external audits.

- Keeping detailed records of manufacturing processes and audit results.

- Updating my processes as EU standards evolve.

- Retaining all documentation and correspondence for at least ten years.

This ongoing commitment ensures my wire tube condenser remains compliant and available in the EU market.

Real-World Example: senjun’s Successful CE Certification for Wire Tube Condensers

At senjun, I have firsthand experience navigating the CE certification process. Ningbo Senjun New Materials Co., Ltd. specializes in the research, development, and production of wire tube condensers and copper aluminum fin heat exchangers for a wide range of applications, including refrigerators, freezers, and medical equipment. When I prepared our wire tube condenser for export to the EU, I followed each step carefully:

- I identified all relevant EU directives and standards.

- I conducted thorough risk assessments and product testing.

- I compiled comprehensive technical documentation.

- I worked with a Notified Body when required.

- I prepared and signed the Declaration of Conformity.

- I affixed the CE mark and maintained all records.

By following this structured approach, I ensured that senjun’s wire tube condensers met all EU requirements. This allowed us to enter the European market smoothly and build trust with our customers.

Costs, Challenges, and Compliance Tips

Typical Costs of CE Certification for Export Condensers

When I plan for CE certification, I always consider the costs involved. These costs can change based on several factors:

- The type of product and its category

- The number of EU directives that apply

- The complexity of testing and safety requirements

- The choice of Notified Body for third-party assessment

- The scope of harmonized standards that must be met

Testing and documentation fees often depend on how many tests are needed and the level of detail required. Notified Bodies may charge significant fees for the Type Examination process. Sometimes, I find discounts through certain labs, especially if I have a long-term partnership or high testing volume. I always request a free assessment and quotation to get a clear idea of the specific costs for my wire tube condenser.

Common Pitfalls and How to Avoid Them

I have learned that avoiding common mistakes can save both time and money during CE certification. Here are some strategies I use:

- I minimize RF noise on cables by reducing signal slew rates and filtering digital signals.

- I make sure all auxiliary equipment used in testing is compliant and comes from trusted manufacturers.

- I select transient protection devices with ratings that match the test lab’s requirements.

- I shield sensitive analog and RF circuits with well-grounded conductive shields.

I also choose suppliers with certifications like CE, ASME, and AHRI. I check their experience and reputation, often by reviewing customer feedback and using online directories. Building strong relationships with suppliers helps me maintain consistent quality and compliance.

Maintaining Compliance After Certification

After I achieve CE certification, I know my work is not finished. I keep my technical documentation up to date and monitor any changes in EU regulations. I conduct regular audits and review my manufacturing processes. If I update my wire tube condenser or change suppliers, I reassess compliance to ensure ongoing market access. Staying proactive helps me avoid costly issues and keeps my products ready for the EU market.

By following the CE certification process, I keep my export condensers compliant and ready for the EU market.

- CE certification builds trust, supports innovation, and opens doors to long-term partnerships with global brands.

- Consulting with notified bodies helps me navigate complex regulations, streamline compliance, and ensure accurate documentation for smooth certification.

FAQ

What documents do I need for CE certification?

I prepare technical documentation, a Declaration of Conformity, test reports, and risk assessments. I keep these records for at least ten years.

How long does the CE certification process take?

I usually complete the process in 4–12 weeks. The timeline depends on product complexity, testing needs, and Notified Body involvement.

Can I export without a Notified Body?

- I can export without a Notified Body if my product falls under self-certification.

- For higher-risk products, I always involve a Notified Body.