Frost on Heat Exchangers: Causes & Prevention

Frost on Heat Exchangers significantly reduces energy efficiency. Air source heat pumps can lose 35–60% efficiency due to frost buildup. Excessive frost also increases energy consumption by forcing frequent defrost cycles. Ningbo Senjun New Materials Co., Ltd. tackles these challenges with advanced solutions like theCopper Fin Heat Exchanger, ensuring optimal performance in diverse applications.

Key Takeaways

- Frost on heat exchangers lowers energy efficiency by 35-60%. Knowing why it happens helps stop it better.

- Managing airflow is very important. Steady airflow avoids uneven heat, stops frost, and boosts Heat Transfer.

- Cleaning and checking heat exchangers often is key. These steps improve how they work and make them last longer.

Causes of Frost Formation

Frost formation on heat exchangers is a complex phenomenon influenced by several environmental and operational factors. Understanding these causes is essential for implementing effective prevention strategies.

Humidity Levels in the Air

High humidity levels significantly contribute to frost formation. When warm, moist air comes into contact with the cold surface of a heat exchanger, the moisture condenses and freezes, forming a frost layer. This layer acts as an insulator, reducing heat transfer efficiency and increasing pressure drop. A study highlights that the relative humidity of the air plays a critical role in determining the threshold temperature for frost formation. For instance, in winter conditions, the combination of high indoor humidity and low outdoor temperatures exacerbates frost buildup, especially in air-to-air heat exchangers.

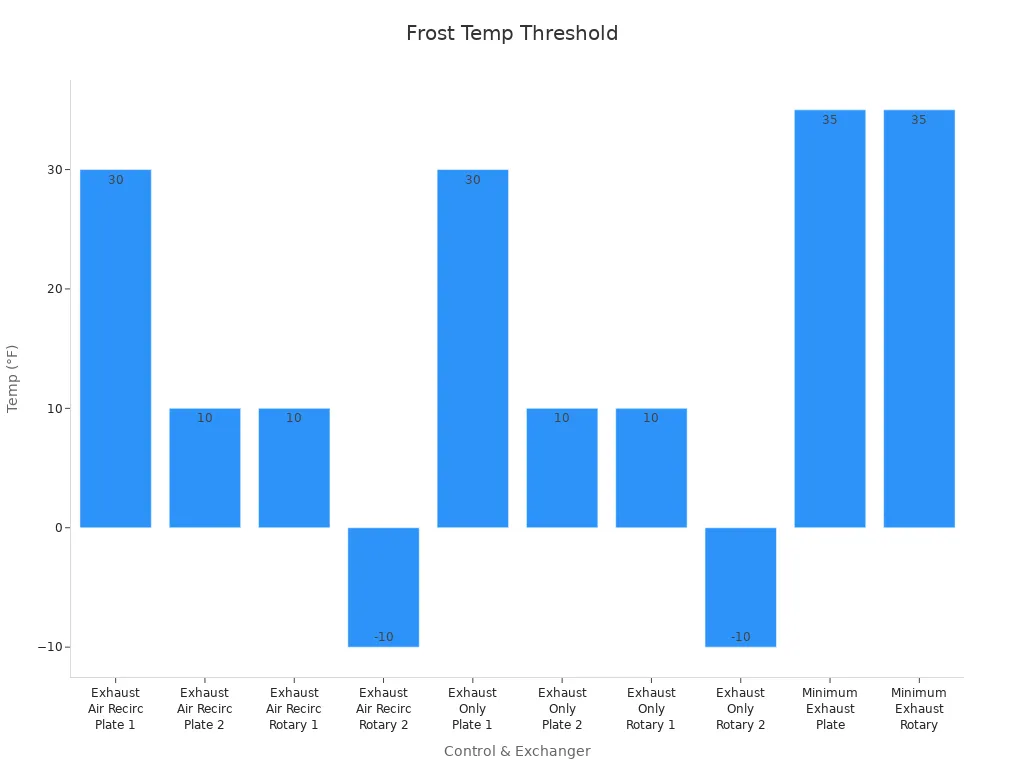

| Frost Control Type | Heat Exchanger Type | Threshold Temperature |

|---|---|---|

| Exhaust Air Recirculation | Plate | 30°F (-1.1°C) |

| Exhaust Air Recirculation | Rotary | 10°F (-12.2°C) |

| Minimum Exhaust Temperature | Plate | 35°F (-1.7°C) |

Low Surface Temperatures

The temperature of The Heat Exchanger's surface directly influences frost formation. Studies reveal that as surface temperatures drop, frost thickness increases. At ultra-low temperatures, unique frost patterns, such as thread-shaped frost, emerge, further reducing heat exchanger efficiency. This correlation underscores the importance of maintaining optimal surface temperatures to minimize frost buildup.

Poor Airflow or Ventilation

Inadequate airflow or ventilation can lead to uneven temperature distribution across the heat exchanger, creating conditions conducive to frost formation. Research indicates that reduced ventilation rates not only degrade indoor air quality but also increase frosting on heat exchangers. Controlled airflow is crucial for maintaining system performance and preventing excessive frost accumulation.

System Design Flaws

Design flaws in heat exchangers can exacerbate frost accumulation. For example, uneven air distribution or poorly insulated components can create cold spots where frost forms more rapidly. Quantitative data shows that frost mass accumulation on windward fins can reach 13.7% after just 60 minutes of frosting. Addressing these design issues is vital for optimizing heat exchanger performance.

- Frost mass accumulation ratios on windward fins:

- 13.7% after 60 minutes of frosting.

- 12.5% after 120 minutes of frosting.

Environmental Conditions in Cold Climates

Cold climates present unique challenges for heat exchangers. Local climatic conditions, such as temperature differences and relative humidity, significantly influence frost formation. For instance, the concept of "Frosting Degree Hours" quantifies the impact of climatic conditions on frost buildup. Data collected from various regions highlights that areas with high humidity and low temperatures experience more severe frosting.

| Key Findings | Description |

|---|---|

| Frosting Degree Hours | Quantifies the impact of climatic conditions on frost formation. |

| Local Climatic Conditions | Frost formation varies significantly based on regional climate data. |

| Relative Humidity | Affects the frosting threshold of return air to the heat exchanger. |

By understanding these causes, businesses can adopt targeted strategies to mitigate frost formation and enhance the efficiency of their systems. Advanced solutions, such as the Copper Fin Heat Exchanger, offer improved performance in challenging environments.

Prevention Strategies

Optimize Airflow Management

Proper airflow management plays a critical role in reducing frost buildup on heat exchangers. I have observed that maintaining consistent airflow prevents uneven temperature distribution, which often leads to frost formation. Increasing the air mass flow rate, for instance, from 0.417 kg/s to 2.5 kg/s, can enhance power output from 14.5 kW to 15.1 kW. This adjustment not only improves heat transfer efficiency but also minimizes energy waste. Additionally, systems with optimized airflow achieve a heat recovery efficiency of up to 95%, significantly reducing operational costs. These results highlight the importance of designing systems with controlled and balanced airflow.

Use Defrosting Systems

Defrosting systems are essential for maintaining the efficiency of heat exchangers in cold environments. I recommend using automatic defrosting mechanisms, such as hot gas bypass or electric defrost systems, to remove frost layers without interrupting operations. These systems work by periodically raising the surface temperature of the heat exchanger, melting the accumulated frost. This approach ensures that the equipment operates at peak efficiency, even in challenging conditions. By integrating defrosting systems, businesses can reduce downtime and extend the lifespan of their heat exchangers.

Install Advanced Sensors and Controls

Advanced sensors and controls provide real-time monitoring and automation, which are invaluable for preventing frost formation. For example, sensors can detect changes in humidity and temperature, allowing the system to adjust its operation proactively. Historical data shows that automation reduces disturbances and improves operational consistency. Additionally, sensor data assists in diagnosing and predicting failures, supporting predictive maintenance and reducing downtime. These technologies not only enhance the reliability of heat exchangers but also contribute to energy efficiency and environmental compliance.

| Feature | Benefit |

|---|---|

| Real-time monitoring | Detects humidity and temperature changes |

| Predictive maintenance | Reduces downtime and repair costs |

| Automation | Improves operational consistency |

Insulate Heat Exchanger Components

Insulating heat exchanger components is another effective strategy to prevent frost formation. I have found that proper insulation minimizes heat loss and prevents cold spots, which are common areas for frost accumulation. High-quality insulation materials, such as polyurethane foam or fiberglass, create a thermal barrier that maintains consistent surface temperatures. This approach not only reduces frost buildup but also enhances the overall energy efficiency of the system. Insulation is a cost-effective solution that delivers long-term benefits for businesses operating in cold climates.

Design Systems for Frost-Resistant Operation

Designing heat exchangers for frost-resistant operation involves addressing potential vulnerabilities during the initial design phase. I always emphasize the importance of incorporating features like uniform air distribution and optimized fin spacing. These design elements reduce the likelihood of frost accumulation by ensuring even temperature distribution across the heat exchanger. For example, increasing the diaphragm wall thickness by 0.1 m can decrease heat exchange in August by approximately 1500 kWh, demonstrating the impact of thoughtful design on energy efficiency. By prioritizing frost resistance in system design, businesses can achieve reliable performance in diverse environmental conditions.

Benefits of Copper Fin Heat Exchangers by senjun

Copper Fin Heat Exchangers, developed by Ningbo Senjun New Materials Co., Ltd., offer exceptional performance in preventing frost formation. The unique properties of copper, such as its high thermal conductivity and resistance to corrosion, make it an ideal material for heat exchangers. These exchangers ensure efficient heat transfer while minimizing frost buildup, even in high-humidity environments. Additionally, the advanced design of Senjun's Copper Fin Heat Exchangers enhances durability and reduces maintenance requirements. By choosing these innovative solutions, businesses can optimize their systems for energy efficiency and long-term reliability.

Tip: Investing in high-quality heat exchangers, like Senjun's Copper Fin Heat Exchangers, can significantly reduce operational costs and improve system performance.

Maintenance Practices

Regular Cleaning of Heat Exchanger Surfaces

I always emphasize the importance of regular cleaning to maintain heat exchanger efficiency. Dirt and scaling act as insulators, hindering heat transfer and increasing energy consumption. Cleaning prevents fouling and ensures optimal operation.

- Cleaning reduces dirt accumulation and scale buildup.

- It improves flow efficiency and reduces energy use.

- The cost of cleaning is justified by the performance recovery it provides.

Regular cleaning not only enhances system performance but also delivers economic benefits. Businesses can save on energy costs while extending the lifespan of their equipment.

Inspect and Replace Worn Components

Worn components compromise system efficiency and increase the risk of frost buildup. I recommend routine inspections to identify damaged parts early. Replacing worn components minimizes unexpected repairs and ensures consistent operation.

| Aspect | Description |

|---|---|

| Preventive Maintenance | Minimizes unexpected repairs and prolongs equipment lifespan. |

| Reactive Maintenance | Leads to higher costs due to unplanned repairs and lost productivity. |

| Long-term Savings | Improves operational efficiency, safety, and energy savings. |

Proactive replacement strategies reduce downtime and prevent costly failures.

Monitor Humidity and Temperature Levels

Monitoring humidity and temperature levels plays a critical role in frost management. Advanced control methods, such as the temperature-humidity-image (T-H-I) defrost control system, classify frost conditions accurately. This approach optimizes defrost timing, reduces false defrost cycles, and improves energy efficiency.

Precise environmental monitoring also helps measure frost thickness and fractal dimensions, enabling businesses to refine defrosting processes. I have seen how these strategies enhance system reliability and reduce operational costs.

Schedule Routine System Inspections

Routine inspections identify potential issues before they escalate. I recommend scheduling inspections to check for airflow obstructions, worn components, and frost buildup. These inspections ensure that systems operate efficiently and prevent costly repairs.

Address Frost Buildup Promptly

Promptly addressing frost buildup prevents operational inefficiencies. I advise using defrosting systems or manual removal methods to eliminate frost layers. This proactive approach maintains heat exchanger performance and reduces energy waste.

Tip: Regular maintenance practices, such as cleaning, monitoring, and inspections, ensure long-term system reliability and cost savings.

Frost formation on heat exchangers can disrupt operations, but proactive strategies ensure long-term efficiency. Measures like airflow optimization, defrosting systems, and advanced technologies, such as the Copper Fin Heat Exchanger, significantly reduce frost buildup. For instance, maintaining downtime below 2% and achieving 98% temperature compliance rates highlight the benefits of effective frost management. Companies like Ningbo Senjun New Materials Co., Ltd. lead the way with innovative solutions that enhance reliability and energy efficiency.

Note: Investing in high-quality systems ensures consistent performance and minimizes operational disruptions.

FAQ

What causes frost to form on heat exchangers?

Frost forms when humid air contacts cold surfaces. Moisture condenses and freezes, reducing heat transfer efficiency and increasing energy consumption.

How can I prevent frost buildup on heat exchangers?

I recommend optimizing airflow, using defrosting systems, and insulating components. These strategies minimize frost accumulation and improve system performance.

Why choose Senjun’s Copper Fin Heat Exchangers?

Senjun’s Copper Fin Heat Exchangers offer high thermal conductivity, durability, and corrosion resistance. These features ensure efficient heat transfer and reduced maintenance needs.

Tip: Regular maintenance and advanced technologies like Senjun’s heat exchangers enhance system reliability and energy efficiency.