Wholesale Fin Tube Heat Exchanger Manufacturer for Optimal Efficiency

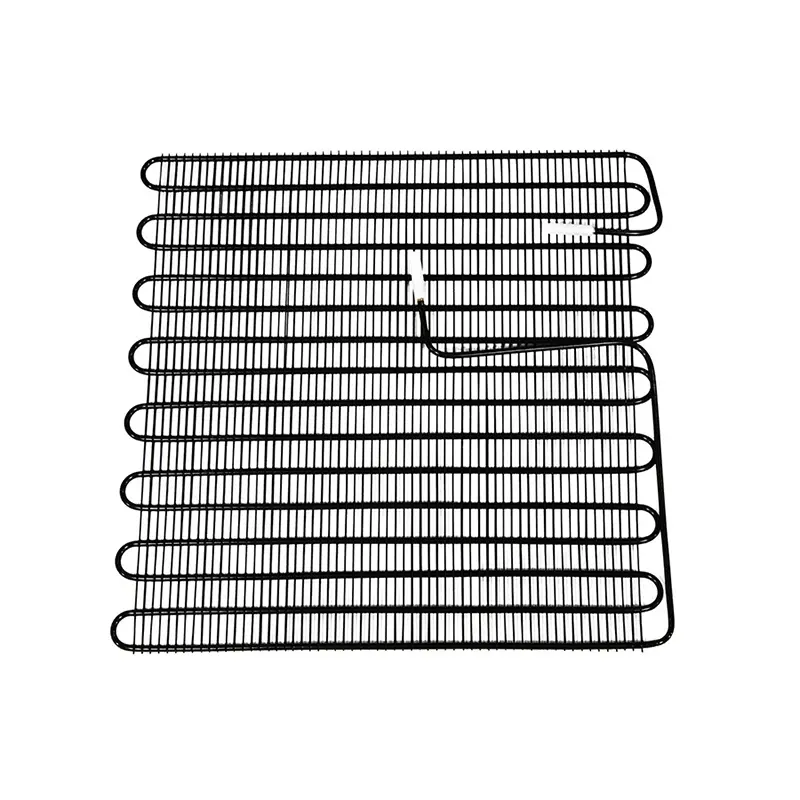

The Fin Tube Heat Exchanger from Ningbo Senjun New Materials Co., Ltd. combines advanced engineering with high efficiency to optimize thermal performance in a variety of applications. Designed to maximize heat transfer while minimizing energy loss, this innovative product features a robust Finned Tube design that increases the surface area for heat exchange. Crafted from high-quality materials, the heat exchanger ensures durability and reliability even in the most demanding industrial environments, Ideal for both heating and cooling applications, it is well-suited for use in HVAC systems, power plants, and petrochemical industries. The compact design allows for easy installation and maintenance, making it a preferred choice for engineers and facility managers alike. With a commitment to sustainability, Ningbo Senjun focuses on providing energy-efficient solutions that meet the highest standards of performance and environmental responsibility. Choose the Fin Tube Heat Exchanger for exceptional heat transfer efficiency and long-lasting service in your thermal management systems

How To Evaluate Fin Tube Heat Exchanger Pioneers in the Field Supplies the World’s Top Brands

When evaluating fin tube heat exchanger pioneers, it’s essential to consider their innovation, reliability, and partnerships with industry leaders. At Ningbo Senjun New Materials Co., Ltd., established in 2010, we have positioned ourselves as a trusted supplier specializing in wire tube condensers and copper-aluminum fin heat exchangers. Our products are integral to numerous applications, including refrigerators, freezers, drinking fountains, and display cabinets, making us a backbone for top global brands. One of the key factors in selecting a supplier is the ability to deliver high-quality and efficient products. Our commitment to research and development allows us to stay ahead of market trends and customer needs. Additionally, we focus on sustainable practices and energy-efficient solutions that not only fulfill operational requirements but also align with global standards in environmental responsibility. By partnering with us, buyers can leverage our expertise and uphold their reputation through reliable heat exchanger solutions. Ultimately, choosing the right fin tube heat exchanger supplier requires due diligence on their capabilities, product range, and commitment to quality. By focusing on companies like Ningbo Senjun, global purchasers can ensure they are aligning with industry leaders that enhance their operational efficiency while delivering superior products to consumers worldwide.

How To Evaluate Fin Tube Heat Exchanger Pioneers in the Field Supplies the World’s Top Brands

| Criteria | Evaluation Method | Rating Scale | Performance Indicators |

|---|---|---|---|

| Heat Transfer Efficiency | Thermal Performance Testing | 1-10 | ΔT, Effectiveness |

| Durability | Long-term Testing | 1-10 | Operating Life, Cycle Count |

| Cost-effectiveness | Cost Analysis | 1-5 | Total Cost of Ownership |

| Environmental Impact | Environmental Assessment | 1-5 | Emissions, Energy Use |

| Innovation | Research & Development | 1-10 | Patents, New Technologies |

Effective Ways To Fin Tube Heat Exchanger Manufacturer Outperforms the Competition

R

Rachel Green

Quality and service are both exceptional! I received prompt assistance from the support team, which made my experience even better.

28 June 2025

I

Isabella White

This product is worth every penny! The quality is impressive, and the customer service team provided excellent support.

17 May 2025

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

L

Lucas Robinson

Impressive quality! Their customer service team is well-trained and very responsive.

09 May 2025

M

Michael Perez

Incredible quality and service! The support team was friendly and efficient.

27 May 2025

C

Charlotte Mitchell

This product is wonderful! The quality is high, and the customer service team excelled in their support.

17 May 2025