Top Fin Heat Exchanger Manufacturers in China - Quality Factory Options

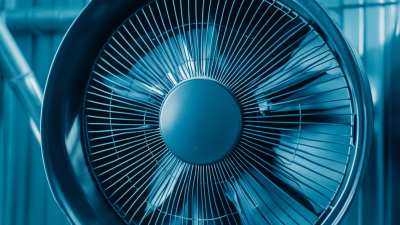

Ningbo Senjun New Materials Co., Ltd. offers a cutting-edge solution in thermal management with its advanced fin heat exchangers. Designed for superior efficiency, these exchangers optimize Heat Transfer in a variety of applications, from HVAC systems to industrial processes. Our fin heat exchangers utilize innovative designs that increase surface area and airflow, ensuring effective temperature regulation while minimizing energy consumption, Constructed from high-quality materials, these products are built to withstand harsh environments and deliver long-lasting performance. The versatility in design allows customization to meet specific client requirements, ensuring compatibility with different systems and enhancing overall energy efficiency, With a commitment to innovation and sustainability, Ningbo Senjun New Materials Co., Ltd. prioritizes solutions that not only meet industry standards but also contribute to a greener future. Trust our expertise in fin heat exchanger technology to elevate your thermal management systems and achieve optimal performance

Simple Ways To Fin Heat Exchanger Where Service Meets Innovation Global Reach

At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on delivering cutting-edge solutions in the HVAC and refrigeration industry since our inception in 2010. Our specialization in wire tube condensers and copper aluminum fin heat exchangers caters to a diverse range of applications, including refrigerators, freezers, drinking fountains, and display cabinets. We combine innovative technology with a profound understanding of customer needs to ensure our products not only meet but exceed industry standards. Our global reach allows us to serve clients across various markets, providing tailored solutions that align with local requirements. By focusing on sustainable practices and advanced manufacturing techniques, we enhance the efficiency and longevity of our heat exchangers. With our commitment to service and innovation, we enable businesses worldwide to optimize their operations, reduce energy consumption, and maintain competitive edges in their respective industries. Choosing Ningbo Senjun means partnering with a company that values quality, integrity, and customer satisfaction. We invite global buyers to explore our product offerings and discover how our expertise can contribute to their operational success.

Simple Ways To Find Heat Exchanger Where Service Meets Innovation Global Reach

| Feature | Description | Impact on Service | Global Reach |

|---|---|---|---|

| Advanced Materials | Use of corrosion-resistant alloys that improve lifespan. | Reduces maintenance costs and downtime. | Applicable in diverse environments worldwide. |

| Compact Design | Space-saving configurations for easier installation. | Enhances serviceability in tight spaces. | Ideal for urban and industrial applications globally. |

| Modular Construction | Components can be replaced individually. | Facilitates ease of service and upgrades. | Supports various regional standards and regulations. |

| IoT Integration | Sensors and connectivity for real-time monitoring. | Improves efficiency and predictive maintenance. | Connects to global cloud systems for data analysis. |

| Energy Recovery Systems | Uses waste heat to optimize energy consumption. | Reduces operational costs significantly. | Sustainable solution adopted in many countries. |

Quick Tips To Fin Heat Exchanger Industry Leaders Global Reach

E

Elena Johnson

Absolutely satisfied with my purchase. The product is built to last, and the customer service staff are very courteous and efficient.

06 July 2025

M

Mia Howard

Unbelievable quality! The customer service team went the extra mile to ensure my satisfaction.

24 May 2025

S

Sebastian Jenkins

Excellent product! The customer support staff were highly professional and very helpful.

09 June 2025

H

Henry Reyes

Superb quality and excellent customer support! The team was very accommodating and knowledgeable.

18 May 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025

E

Ethan Taylor

Fantastic durability and quality! The after-sales team was extremely professional and insightful.

08 June 2025