Evaporator in Refrigeration System - China Manufacturer & Factory Solutions

When it comes to optimizing your refrigeration system, we know the importance of quality components like our evaporators. As a manufacturer based in China, we specialize in delivering top-notch evaporators that meet the rigorous standards of refrigeration system factories. Our products are designed to enhance efficiency and durability, ensuring reliable performance in various applications, At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on being a trusted supplier for businesses looking to improve their refrigeration solutions. Whether you're in need of standard models or customized evaporators, our team is ready to cater to your specific needs, By choosing us, you’re not just selecting a product; you’re opting for a partnership with a dedicated manufacturer who understands the demands of the industry. Let's work together to elevate your refrigeration systems today!

Tips & Tricks for Evaporator In Refrigeration System Factories For the Current Year Now Trending

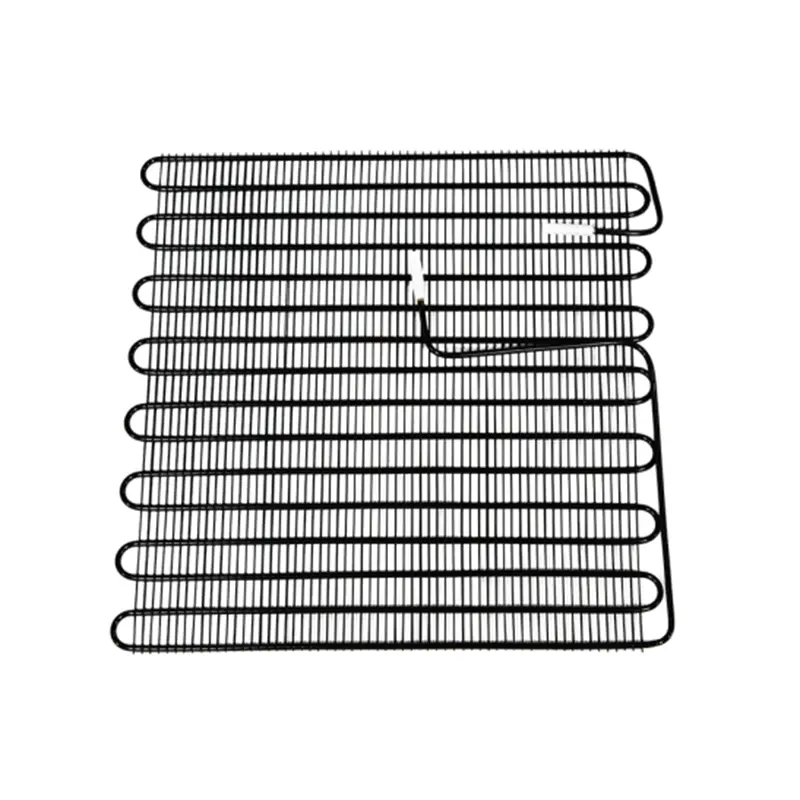

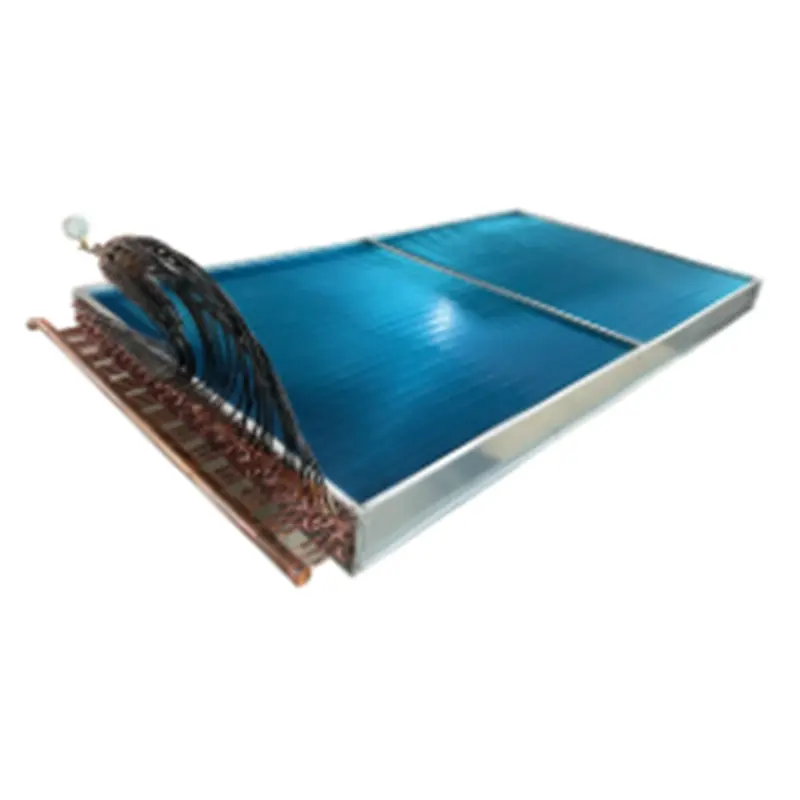

In the fast-evolving landscape of refrigeration technology, optimizing the performance of evaporators is crucial for factories aiming to enhance efficiency and reduce operational costs. At Ningbo Senjun New Materials Co., Ltd., we emphasize innovative approaches in our wire tube condensers and copper aluminum fin heat exchangers, designed for various applications including refrigerators, freezers, and display cabinets. Here are some trending tips for maximizing the efficiency of evaporators in your refrigeration systems this year. Firstly, proper insulation and maintenance play key roles in improving evaporator performance. Regularly checking for leaks and ensuring that insulation is intact can significantly reduce energy losses, promoting an efficient cooling cycle. Moreover, utilizing advanced materials in fabrication—such as those developed by our team—can enhance thermal conductivity and heat exchange capacity, leading to faster cooling times and reduced energy consumption. Secondly, staying updated with the latest technologies and design practices can lead to substantial performance gains. For instance, integrating intelligent controls allows for real-time monitoring and adaptability in operational parameters, ensuring that the evaporators function optimally under varying load conditions. By leveraging the knowledge and innovations from Ningbo Senjun New Materials, global buyers can not only improve their production processes but also align with sustainability goals, significantly lowering their environmental impact while maximizing cooling efficiency.

Tips & Tricks for Evaporator In Refrigeration System Factories For the Current Year Now Trending

| Tip/Trick | Description | Benefit | Popularity Rating (1-5) |

|---|---|---|---|

| Regular Maintenance | Schedule routine checks to ensure evaporator efficiency. | Prolongs lifespan and reduces energy consumption. | 5 |

| Check Refrigerant Levels | Monitor and adjust refrigerant to optimal levels. | Improves cooling efficiency. | 4 |

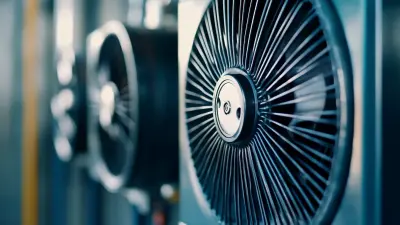

| Inspect Airflow | Ensure unobstructed airflow to evaporators. | Enhances heat exchange efficiency. | 4 |

| Use Insulation | Incorporate insulation around refrigerant lines. | Reduces energy loss. | 3 |

| Upgrade Components | Invest in modern, energy-efficient evaporator models. | Increases overall system efficiency. | 4 |

Champions of Evaporator In Refrigeration System Factories Dominates Industry Giant

S

Samuel Carter

I can’t get over the quality! The customer service team was incredibly professional and responsive.

17 May 2025

J

Jacob Morgan

Very impressed with this product! The quality is superb and the after-sales service was extremely helpful.

01 June 2025

E

Ethan Fisher

Impressive quality! The after-sales support team was attentive and provided great service.

15 June 2025

S

Scarlett Martinez

This product is of outstanding quality! The after-sales support staff were knowledgeable and eager to help.

18 June 2025

J

Jacob Reed

Fantastic craftsmanship! The support team was polite and solved my queries efficiently.

11 June 2025

E

Ethan Gonzalez

Very high quality and attentive service! The after-sales team is exceptionally professional.

12 June 2025