Top China Suppliers for Quality Evaporator Coil Coolers

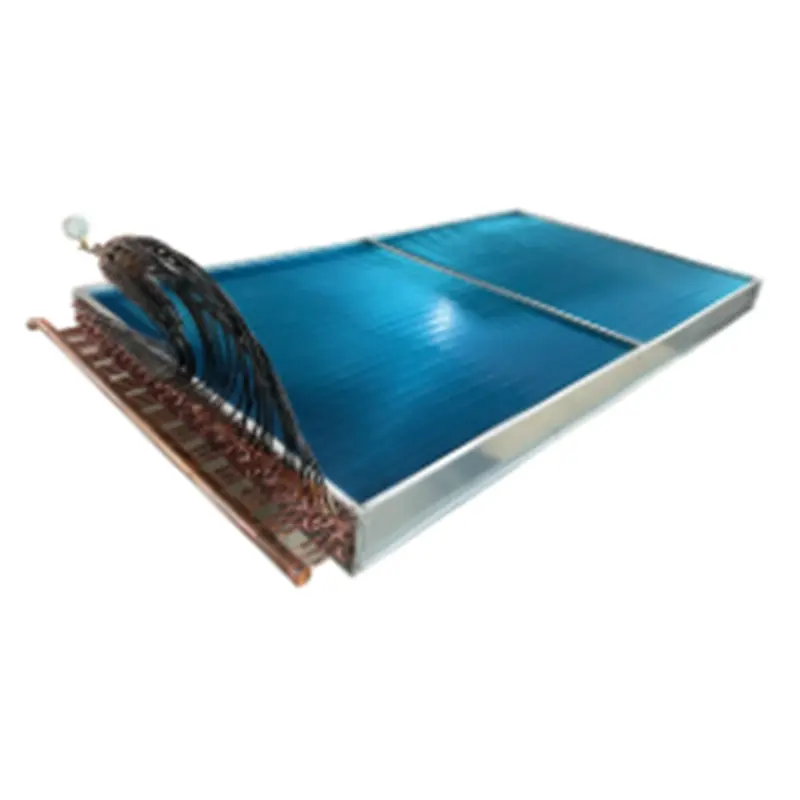

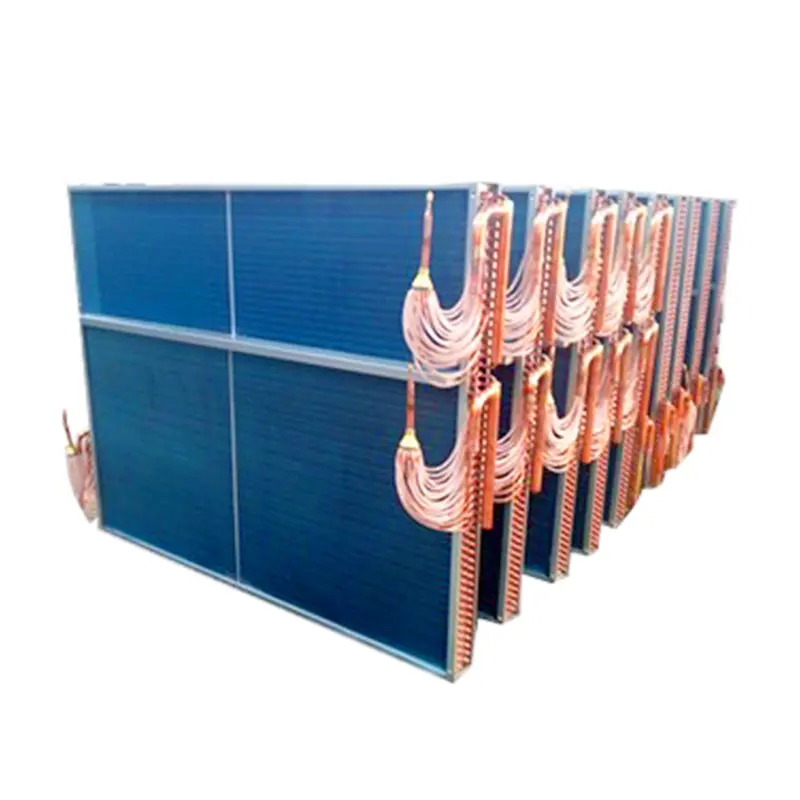

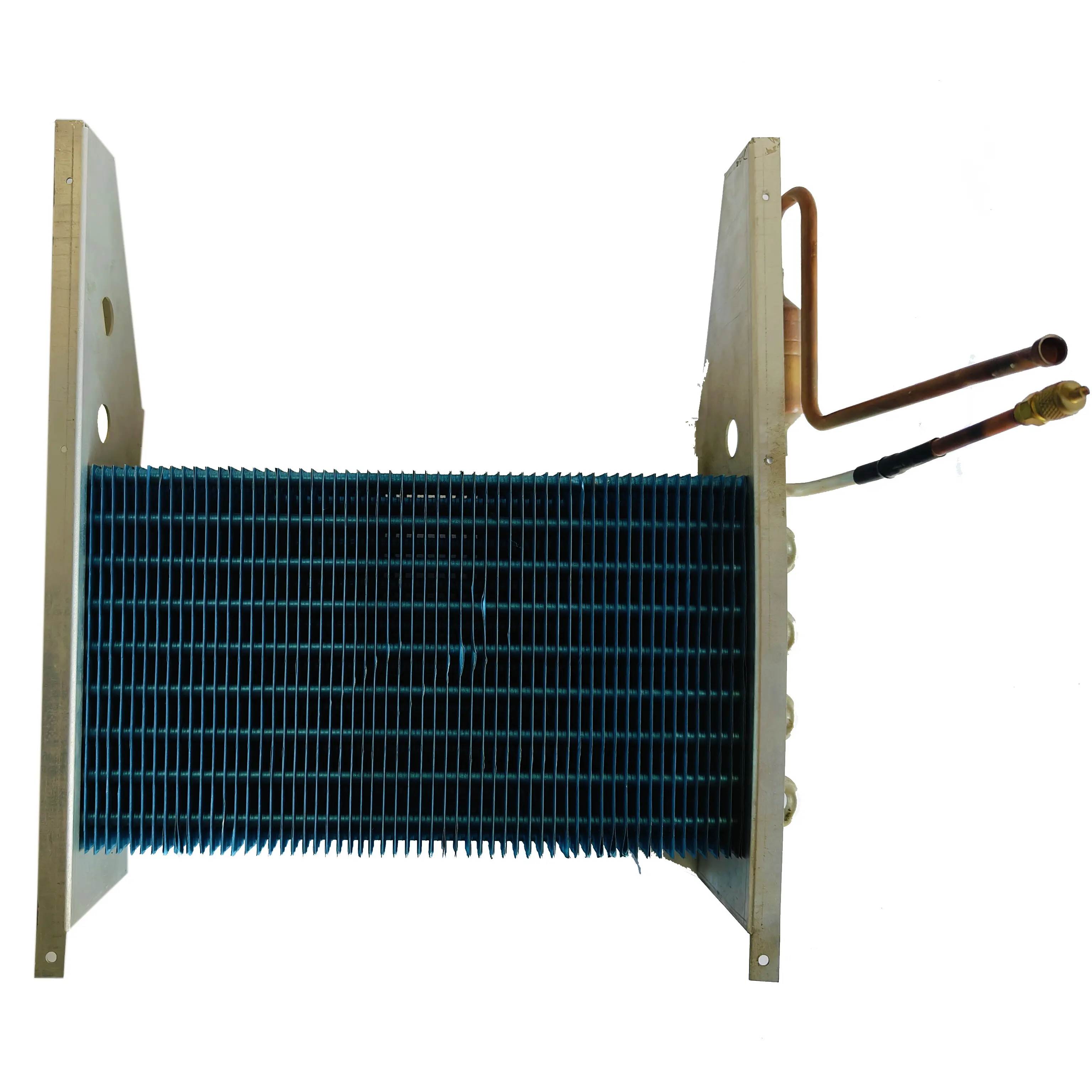

Experience superior cooling efficiency with the Evaporator Coil Cooler from Ningbo Senjun New Materials Co., Ltd. Engineered for optimal heat exchange, this high-performance coil is designed to enhance refrigeration systems in various applications, including commercial and industrial settings. Crafted from premium materials, our evaporator coil ensures durability and long-lasting performance while maintaining energy efficiency, The innovative design features advanced fin and tube technology, maximizing airflow and minimizing energy consumption. This ensures a consistent and reliable cooling experience, essential for preserving temperature-sensitive goods. Easy to install and maintain, the Evaporator Coil Cooler is ideal for both new installations and system upgrades, With a commitment to quality and customer satisfaction, Ningbo Senjun New Materials Co., Ltd. stands as a trusted partner in delivering effective cooling solutions. Discover the difference that our Evaporator Coil Cooler can make in your operations, optimizing performance while reducing energy costs

Effective Ways To Evaporator Coil Cooler Service Factory

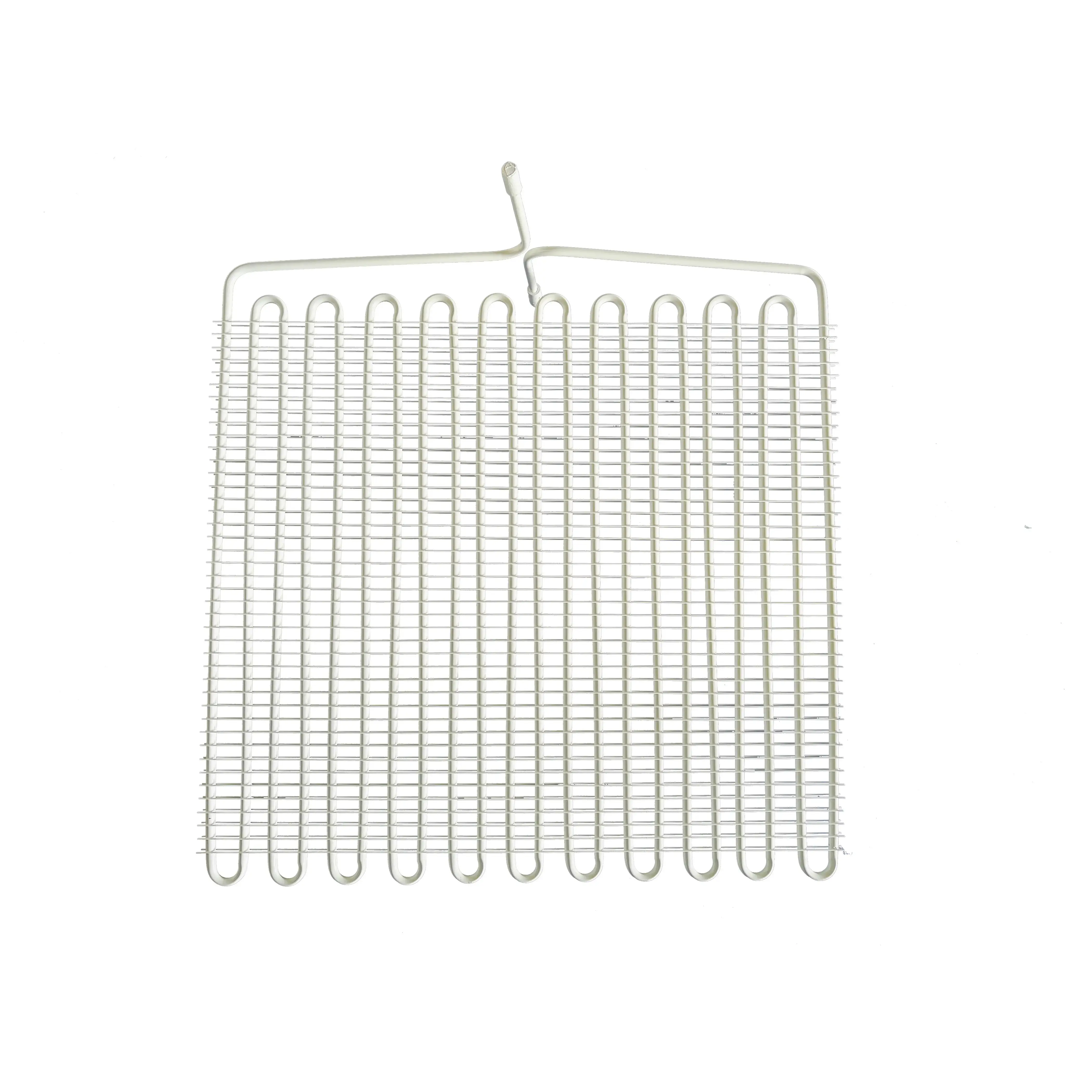

When it comes to maintaining the efficiency and longevity of your evaporator coil cooler systems, ensuring frequent and effective service is vital. At Ningbo Senjun New Materials Co., Ltd., we specialize in the production of top-quality wire tube condensers and copper aluminum fin heat exchangers tailored for various applications, including refrigerators, freezers, and display cabinets. Founded in 2010, our commitment to research and development empowers us to deliver innovative cooling solutions that meet the ever-evolving demands of the global market. Effective service for evaporator coil cooler systems encompasses a few key strategies. First, regular inspection and maintenance are crucial to prevent excessive ice buildup, which can impede cooling performance and energy efficiency. Our expert team recommends implementing a scheduled maintenance plan that includes cleaning coils, checking refrigerant levels, and inspecting for any signs of wear and tear. Secondly, investing in quality components—like those manufactured at our facility—can enhance system reliability and reduce downtime. By choosing Ningbo Senjun's high-performance products, global purchasers can not only secure reliable cooling solutions but also significantly reduce operational costs in the long run. Our dedication to quality and service excellence ensures that every product we deliver meets international standards, making us a preferred partner for businesses worldwide seeking to optimize their cooling systems. With our expertise and innovative products, we help you achieve effective evaporator coil cooler service and ensure your operations run smoothly year-round.

Effective Ways To Evaporator Coil Cooler Service Factory

| Service Type | Frequency | Estimated Time (hours) | Cost Range ($) | Description |

|---|---|---|---|---|

| Cleaning | Monthly | 2 | 50-100 | Remove dust and debris from coils to improve efficiency. |

| Inspection | Quarterly | 1.5 | 75-150 | Check for signs of wear, leaks, and proper operation. |

| Refrigerant Check | Biannual | 2 | 100-200 | Ensure correct levels of refrigerant for optimal performance. |

| Component Replacement | As needed | 2-4 | 200-500 | Replace worn out components for improved efficiency. |

| Full System Check | Yearly | 3 | 150-300 | Comprehensive review of the entire cooling system. |

China Top Evaporator Coil Cooler Outperforms the Competition Trusted by Pros

C

Chloe King

I’m very pleased with this product! The quality is exceptional, and the after-sales service was outstanding.

16 May 2025

B

Benjamin Graves

The quality is excellent! The customer service team was friendly and very communicative.

08 June 2025

S

Sophia Young

Excellence in both product and service! The after-sales team provided the assistance I needed.

20 May 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025

L

Lucas Turner

What a great product! Quality is outstanding, and the customer service was very professional.

06 June 2025