Dry Cooler Vs Air Cooled Condenser: Top China Manufacturers & Factories

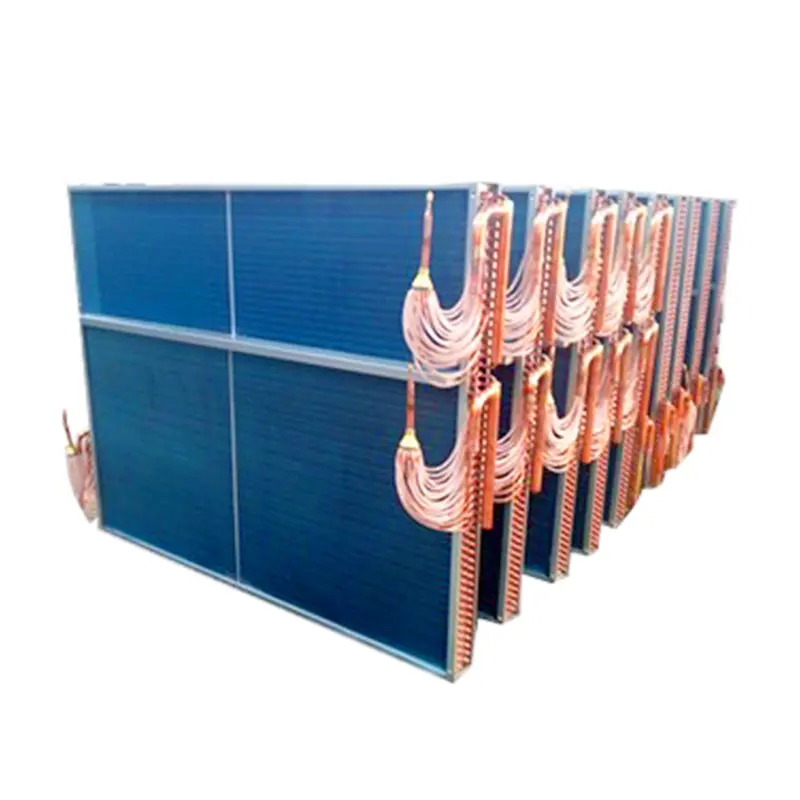

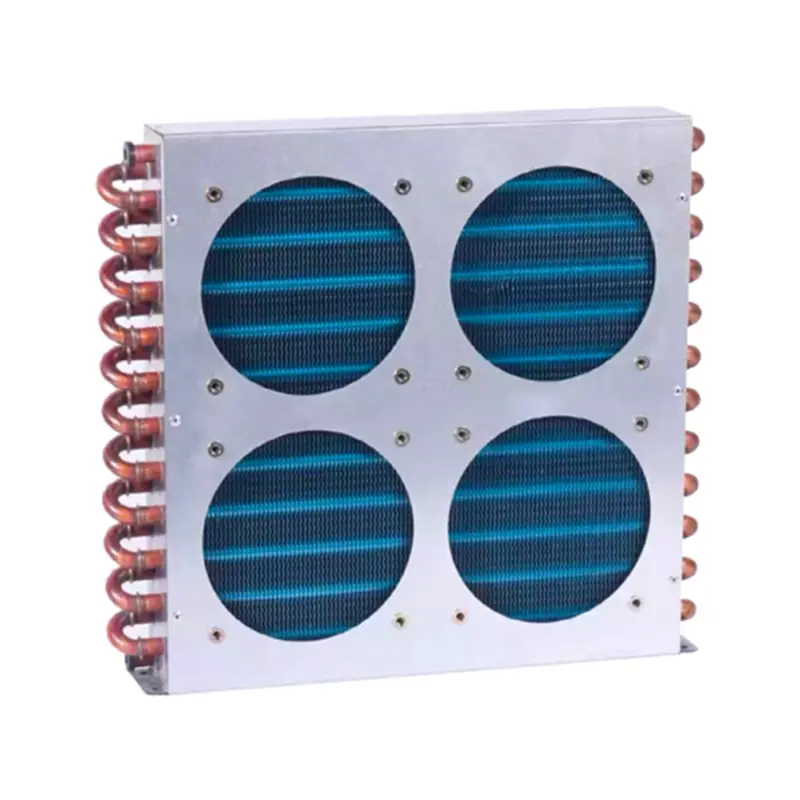

When exploring the best cooling solutions for your factory, the choice between dry coolers and Air Cooled Condensers is crucial. I’m here to share insights on how these systems differ and which one might suit your needs best. With dry coolers, you often benefit from higher efficiency and lower operational costs, making them ideal for industries that value energy savings. On the other hand, air cooled condensers are typically easier to install and offer solid performance in various climates, As a supplier in China, Ningbo Senjun New Materials Co., Ltd. specializes in providing high-quality cooling solutions tailored to your requirements. We understand the importance of reliability and efficiency in your operations. Partnering with us means accessing expert advice and top-notch products that can elevate your factory’s performance. Let’s make your cooling solutions smarter and more efficient together!

Comprehensive Comparison of Dry Cooler Vs Air Cooled Condenser Factories Trusted by Pros Delivers Unmatched Quality

In the competitive landscape of cooling technology, understanding the differences between a dry cooler and an air-cooled condenser is crucial for global procurement professionals. Both options serve unique purposes in various applications, but their efficiencies and reliability can significantly influence the performance of refrigeration systems. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on delivering top-quality wire tube condensers and copper aluminum fin heat exchangers that cater to a diverse range of cooling needs, including refrigerators, freezers, and display cabinets. Dry coolers are designed to dissipate heat through air without the need for water, making them ideal for environments where water access is limited or where sustainability practices are prioritized. On the other hand, air-cooled condensers also utilize ambient air for cooling but are typically integrated into systems that require direct contact with refrigerants. The choice between the two involves careful consideration of factors such as energy efficiency, operational cost, and environmental impact. By leveraging our expertise since 2010, we ensure that our products meet the highest standards, providing unmatched quality that professionals trust. At Ningbo Senjun, we believe in empowering our clients with the knowledge needed to make informed decisions regarding their cooling solutions. Our commitment to research and development has positioned us as a trusted provider of innovative heat exchange technologies, enhancing productivity and reliability in businesses worldwide. Whether you opt for a dry cooler or an air-cooled condenser, our products are engineered to deliver exceptional performance, tailored to your specific needs.

Comprehensive Comparison of Dry Cooler Vs Air Cooled Condenser Factories Trusted by Pros Delivers Unmatched Quality

| Feature | Dry Cooler | Air Cooled Condenser |

|---|---|---|

| Cooling Efficiency | High efficiency in low ambient temperatures | More efficient in high ambient temperatures |

| Installation Cost | Generally lower due to simpler design | Higher due to complex components |

| Maintenance Requirement | Low maintenance needed | Regular maintenance required |

| Environmental Impact | Uses less energy | Higher energy consumption |

| Typical Applications | Industrial chillers, refrigeration | HVAC systems, large scale cooling |

| Lifespan | 15-20 years | 10-15 years |

The Ultimate Guide to Dry Cooler Vs Air Cooled Condenser Factories Trusted by Pros Custom Solutions,

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

J

James Wilson

Exceptional quality! The after-sales service representatives were responsive and educated, making me feel valued.

18 June 2025

E

Emma Allen

I love the quality of this product. The customer service representatives were also extremely helpful and proactive!

10 May 2025

I

Isabella Williams

High-quality product with helpful and responsive customer service! A truly satisfying experience.

13 May 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

L

Lucas Robinson

Impressive quality! Their customer service team is well-trained and very responsive.

09 May 2025