Wholesale Dry Cooler Unit Air Cooled Condenser - Top Manufacturers & Suppliers

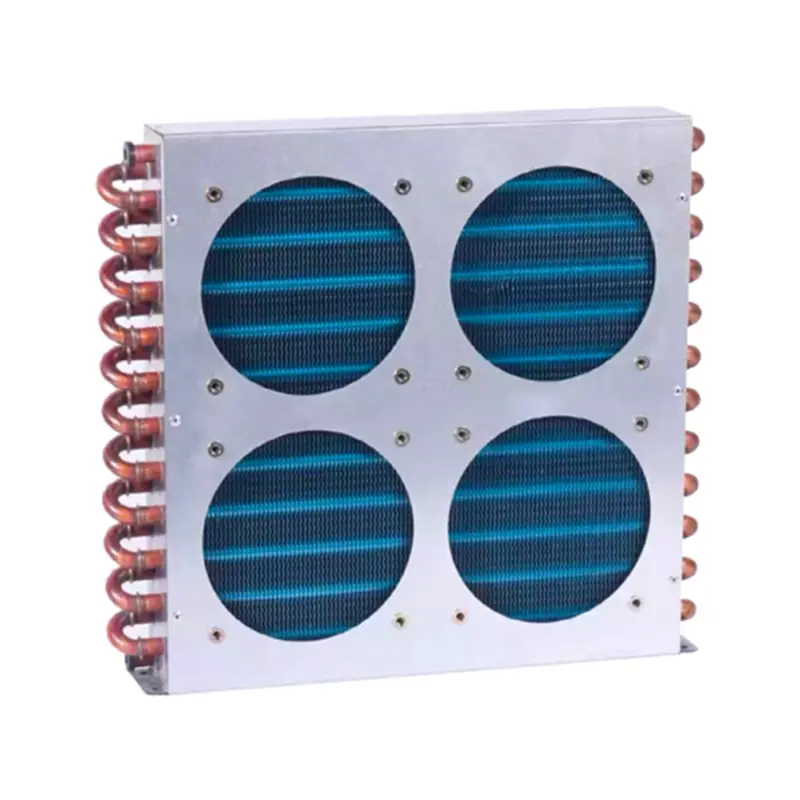

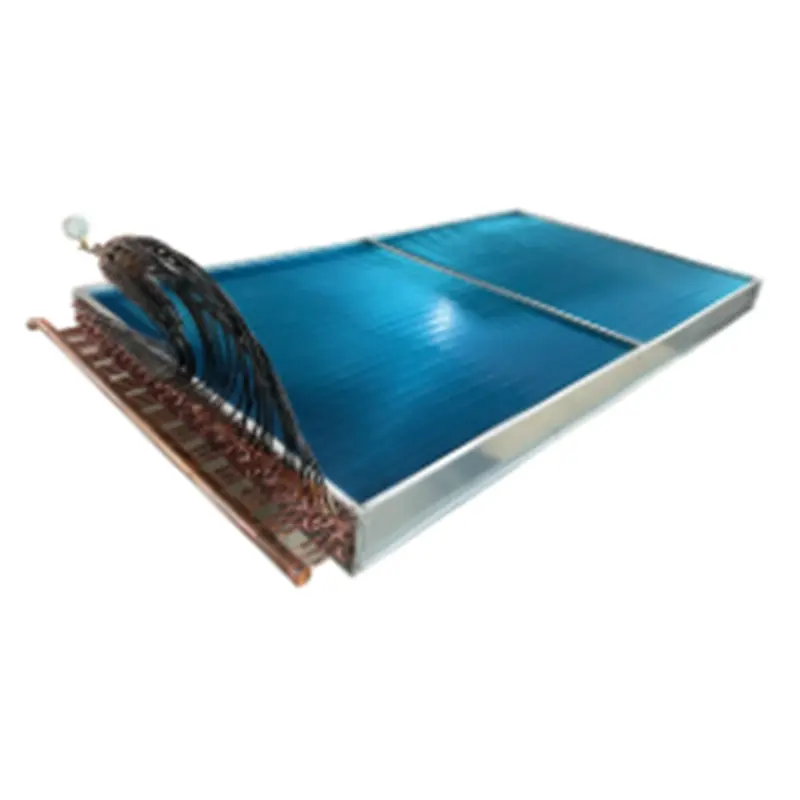

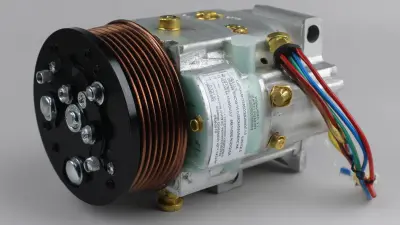

As a leader in the production of Dry Cooler Unit Air Cooled Condensers, we pride ourselves on delivering top-notch quality from our factory in China. We, at Ningbo Senjun New Materials Co., Ltd., understand the diverse needs of our clients in various industries. Our condensers are engineered with advanced technology to ensure optimal performance, durability, and energy efficiency, Manufactured in our state-of-the-art facilities, our products undergo strict quality control processes to meet international standards. We focus on providing customized solutions that cater to specific requirements, making us a preferred partner for B2B purchasers, By choosing our dry cooler units, you gain access to reliable and efficient cooling solutions that can enhance your operational efficiency. Whether you are seeking manufacturers or factories that prioritize quality and performance, we are here to meet your expectations. Let's collaborate to elevate your cooling needs to the next level!

Best Methods To Dry Cooler Unit Air Cooled Condenser Factory Global Reach For the Current Year

In today's competitive market, selecting the right air-cooled condenser for your cooling systems is crucial for efficiency and sustainability. At Ningbo Senjun New Materials Co., Ltd., we have been at the forefront of innovation since our establishment in 2010, focusing on advanced wire tube condensers and copper aluminum fin heat exchangers. Our products are ideal for a variety of applications including refrigerators, freezers, drinking fountains, and display cabinets, serving clients across the globe. To maximize the performance of your cooling systems, it's essential to understand the best methods to dry your cooler unit air-cooled condenser. One effective technique is to optimize airflow by ensuring that there are no obstructions around the condenser unit. Additionally, regular maintenance such as cleaning the fin surfaces can significantly enhance heat exchange efficiency, prolonging the lifespan of your equipment. By adopting these practices, businesses can minimize downtime and improve operational reliability. As a global leader in the manufacturing of condensers, Ningbo Senjun is committed to providing high-quality solutions that cater to diverse industrial needs. Our extensive research and development efforts focus on creating products that not only meet but exceed international standards. By choosing our condensers, procurement professionals will find a dependable partner that supports their sustainability goals while delivering exceptional performance year after year.

Best Methods To Dry Cooler Unit Air Cooled Condenser Factory Global Reach For the Current Year

| Region | Drying Method | Efficiency (%) | Cost ($/unit) | Environmental Impact (Low, Medium, High) |

|---|---|---|---|---|

| North America | Forced Air Drying | 85 | 1200 | Medium |

| Europe | Indirect Evaporation | 90 | 1500 | Low |

| Asia | Heat Exchanger | 95 | 1400 | Low |

| South America | Solar Drying | 80 | 1000 | Low |

| Africa | Natural Ventilation | 70 | 800 | High |

Why Consider Dry Cooler Unit Air Cooled Condenser Factory For the Current Year Your End-to-End Solution

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

A

Abigail Scott

Amazing product! The quality surpassed my expectations, and the support team was incredibly responsive.

25 May 2025

G

Grace Hall

Truly delighted with my purchase. The quality is outstanding, and the after-sales service exceeded my expectations.

30 May 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025

C

Chloe Cooper

Very high quality with exceptional support! The after-sales team truly cares about their customers.

08 June 2025