Wholesale Dry Condenser Units - Top Suppliers & Factory Direct Deals

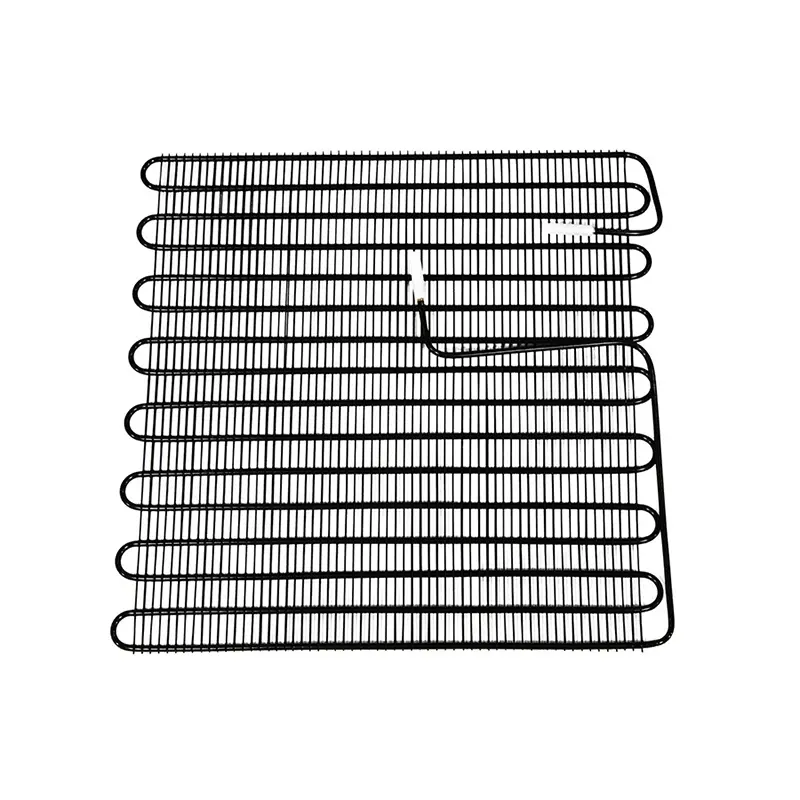

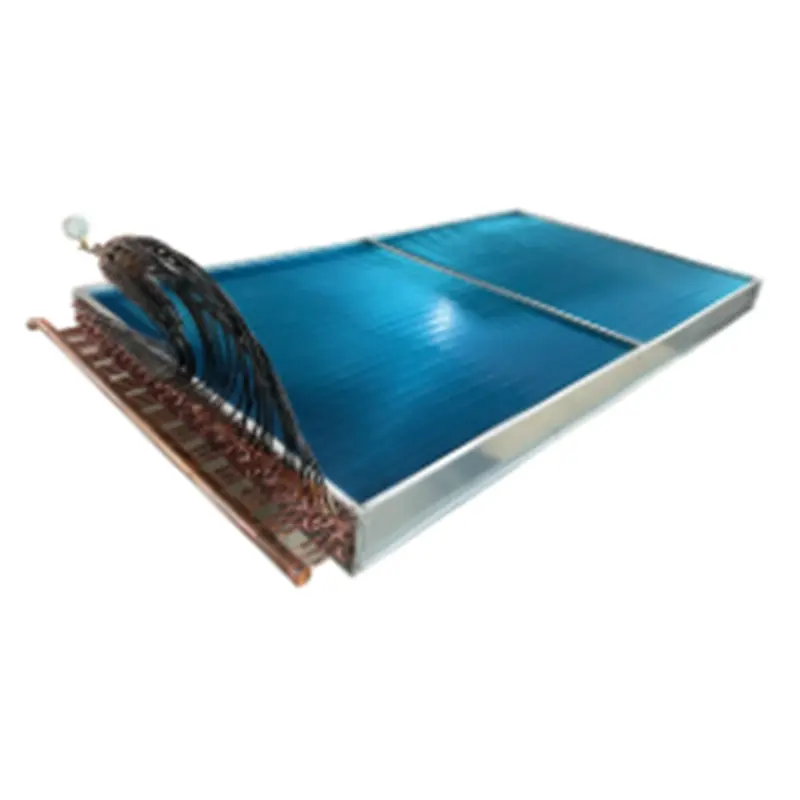

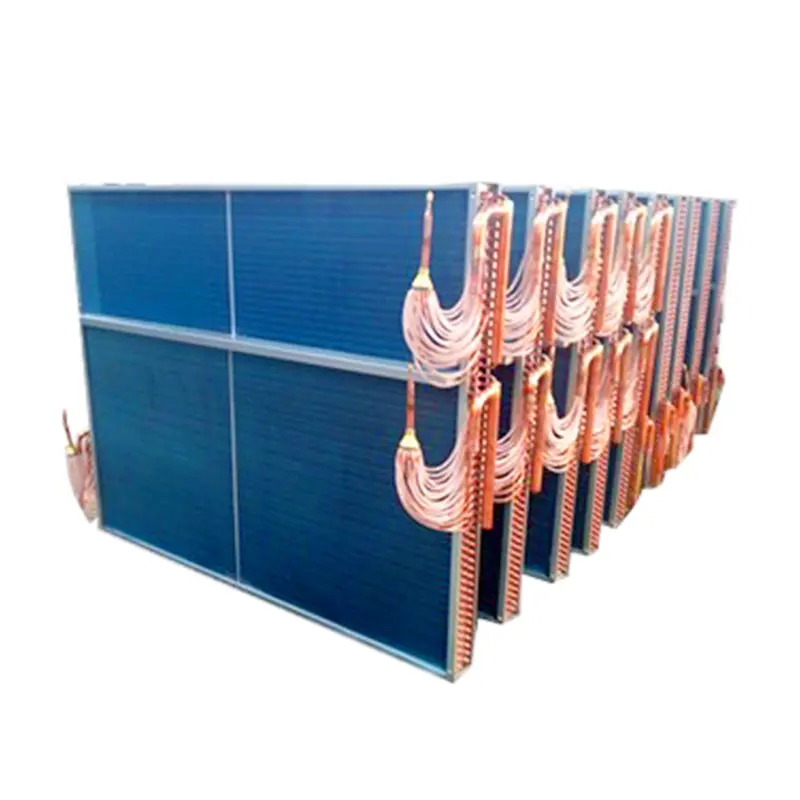

Discover the advanced Dry Condenser Units from Ningbo Senjun New Materials Co., Ltd., designed to enhance efficiency and sustainability in various industrial applications. These units utilize cutting-edge technology to effectively dissipate heat, ensuring optimal performance while minimizing environmental impact. Engineered for reliability, they are constructed from high-quality materials that withstand extreme conditions, providing longevity and reduced maintenance costs, The Dry Condenser Units are particularly suited for cooling systems in power plants, manufacturing facilities, and refrigeration processes. Their compact design allows for easy installation in diverse setups, while their innovative design guarantees maximum Heat Transfer efficiency, With a commitment to innovation and quality, Ningbo Senjun New Materials Co., Ltd. stands at the forefront of providing eco-friendly solutions that meet the demanding needs of modern industries. Choose our Dry Condenser Units for unparalleled performance and a greener future. Enhance your operations today with our reliable and efficient cooling solutions

Best Methods To Dry Condenser Units Your End-to-End Solution Application

When it comes to ensuring the efficient operation of cooling systems like refrigerators, freezers, and display cabinets, proper maintenance of condenser units is essential. At Ningbo Senjun New Materials Co., Ltd., we specialize in the production of wire tube condensers and copper-aluminum fin heat exchangers, and we understand that effective drying of these units can significantly optimize performance. One of the best methods to dry condenser units is through the use of forced air drying, where warm, dry air is circulated around the unit to remove moisture. This technique not only facilitates quick drying but also helps in preventing the formation of rust and corrosion, which can severely impact the longevity and efficiency of the components. Additionally, integrating desiccants into the drying process can absorb excess moisture, further enhancing the effectiveness of this method. For global buyers seeking reliable components for their refrigeration systems, partnering with a company committed to quality and innovation like Ningbo Senjun is vital. Our dedicated research and development efforts since 2010 ensure that our products not only meet but exceed international standards. By leveraging our expertise in condenser technologies, clients can maintain optimal performance and reliability in their cooling applications. Trust us for your end-to-end solution needs in condenser units and experience the difference in quality and efficiency.

Best Methods To Dry Condenser Units Your End-to-End Solution Application

| Method | Description | Effectiveness | Time Required | Recommended Frequency |

|---|---|---|---|---|

| Air Drying | Utilizing airflow to evaporate moisture from condenser units. | Moderate | 2-5 hours | Weekly |

| Heat Gun Drying | Applying heat directly to evaporate moisture quickly. | High | 30-60 minutes | As needed |

| Dehumidifier Use | Using a dehumidifier to reduce moisture in the area. | High | 1-2 hours | Weekly |

| Vacuum Pump Drying | Creating a vacuum to remove moisture from the unit. | Very High | 1-3 hours | Monthly |

| Natural Drying | Letting the unit air dry over time. | Low | Varies | Every 6 months |

Uncovering Dry Condenser Units Manufacturer Pioneers in the Field

I

Isabella White

This product is worth every penny! The quality is impressive, and the customer service team provided excellent support.

17 May 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

G

Grace Hall

Truly delighted with my purchase. The quality is outstanding, and the after-sales service exceeded my expectations.

30 May 2025

L

Liam Bennett

I’ve had nothing but a positive experience! The product is of excellent quality and service team is very helpful.

15 June 2025

M

Mia Foster

Outstanding quality! The customer service representatives were extremely professional and attentive.

06 July 2025

L

Lucas Hall

This product is fantastic! Their support team is responsive and genuinely cares about customer satisfaction.

13 June 2025