Different Types of Heat Exchanger Suppliers in China Factories

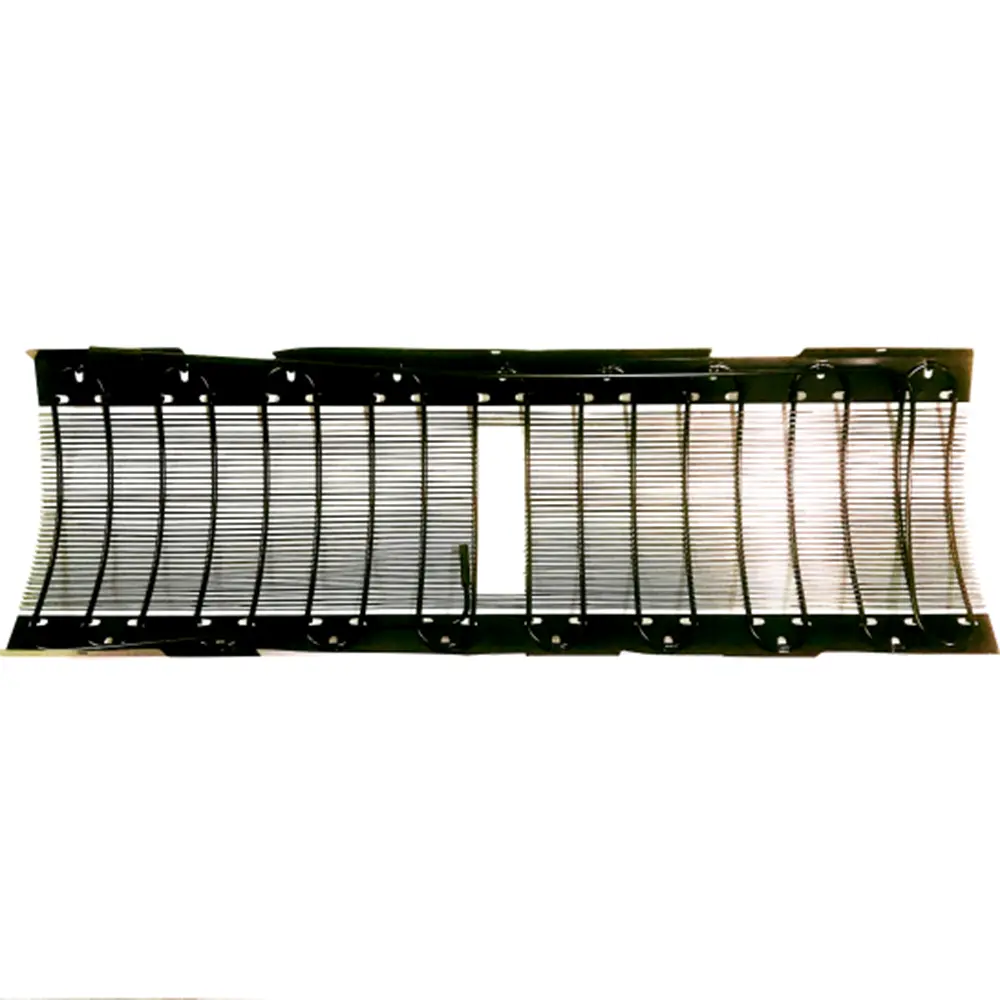

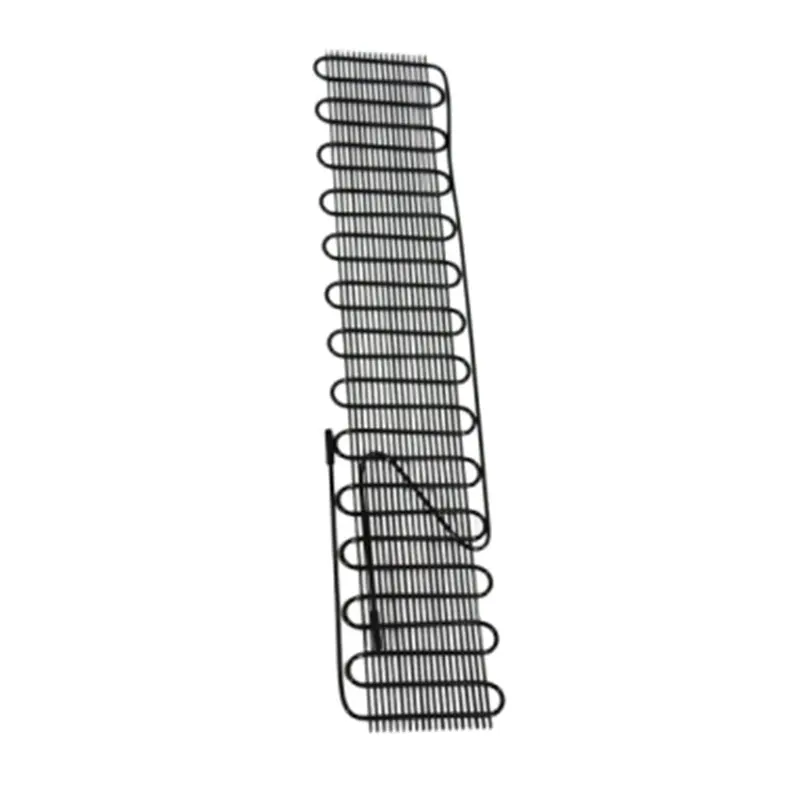

At Ningbo Senjun New Materials Co., Ltd., we are committed to delivering high-quality Heat Exchanger solutions tailored to diverse industrial applications. Our extensive range of heat exchangers includes shell and tube, plate, air-cooled, and spiral types, each designed to enhance thermal efficiency and energy conservation, Shell and tube heat exchangers are ideal for high-pressure and temperature applications, offering durability and performance. Plate heat exchangers provide a compact design with excellent heat transfer capabilities, making them perfect for food processing and chemical industries. Our air-cooled units are perfect for outdoor applications where water resources are limited, while spiral heat exchangers maximize heat transfer in a minimal footprint, Each product is engineered with precision, ensuring reliability and longevity. With a focus on innovation and quality assurance, we aim to exceed customer expectations and contribute to sustainable industrial practices. Trust Ningbo Senjun New Materials Co., Ltd. for your heat exchanger needs and experience unparalleled efficiency

Best Ways To Different Types Of Heat Exchanger Products Now Trending

In the dynamic world of heat exchanger products, understanding the various types and their applications is essential for global buyers looking to optimize their operations. At Ningbo Senjun New Materials Co., Ltd., we specialize in innovative wire tube condensers and copper aluminum fin heat exchangers that cater to a wide array of industries, including refrigeration, freezing, drinking fountain systems, and display cabinets. As trends evolve, it's crucial to stay informed about the best-performing products that not only meet industry standards but also enhance energy efficiency and sustainability. Currently, the market is witnessing a surge in demand for eco-friendly heat exchangers. These products not only minimize environmental impact but also offer superior performance in various conditions. Our range of designed condensers and heat exchangers utilizes advanced materials and technology, ensuring long-lasting durability and efficiency. As global purchasers prioritize sustainability, investing in products that significantly reduce energy consumption is more critical than ever. Moreover, integrating smart technology into heat exchangers is becoming increasingly popular. This trend allows for real-time monitoring of performance and maintenance needs, which can help suppliers and buyers alike in making informed decisions. As we continue to innovate and adapt to the changing market landscape, Ningbo Senjun New Materials Co., Ltd. is poised to meet the needs of our international clients by delivering cutting-edge heat exchanger solutions that align with their operational goals and sustainability commitments.

Best Ways To Different Types Of Heat Exchanger Products Now Trending

| Heat Exchanger Type | Material | Efficiency Rating | Applications | Trending Features |

|---|---|---|---|---|

| Shell and Tube | Stainless Steel | 95% | Oil Refining, Power Plants | Compact Design, High Pressure |

| Plate | Titanium | 90% | HVAC, Food Processing | Easy Cleaning, High Temperature Resistance |

| Air-Cooled | Aluminum | 85% | Refrigeration, Chemical Processing | Energy Efficient, Low Maintenance |

| Double Pipe | Copper | 80% | Pharmaceutical, HVAC | Simple Design, Cost-Effective |

| Fin Fan | Steel | 88% | Chemical, Petrochemical | Modular Design, Enhanced Airflow |

Best Brands For Different Types Of Heat Exchanger Products in 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

I

Isabella Foster

Remarkable quality! The support staff is educated and attentive, making the entire process seamless.

28 May 2025

A

Ava Diaz

I can highly recommend this product! The quality is great, and their customer service is professional and helpful.

09 June 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

L

Lily Carter

Incredible quality with a flawless design! The after-sales team was very supportive and attentive.

16 May 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025