Wholesale Different Types of Heat Exchanger Factory Manufacturers

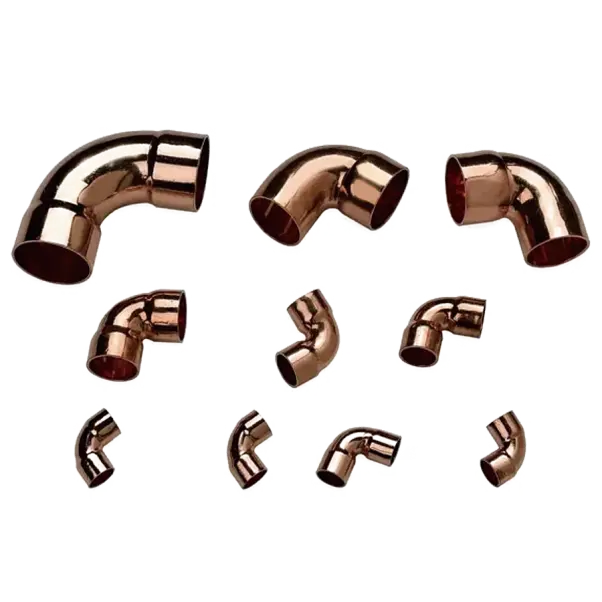

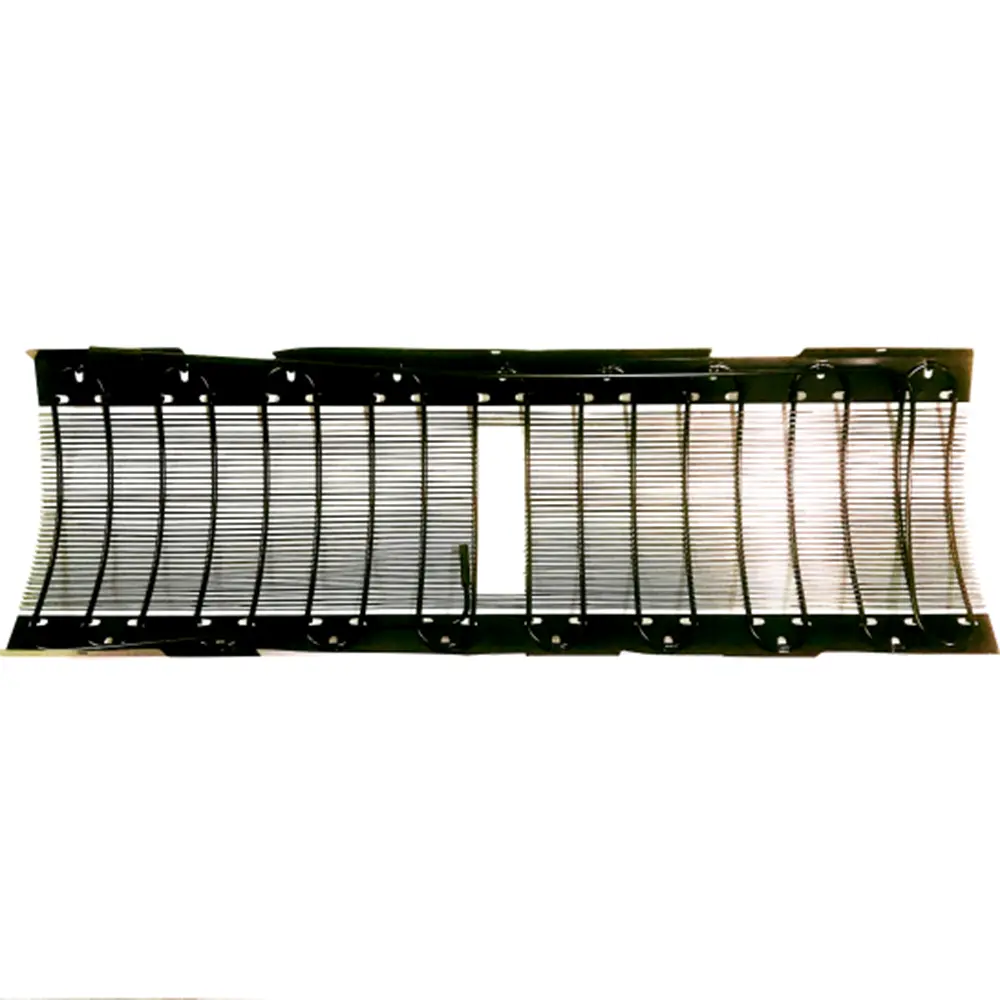

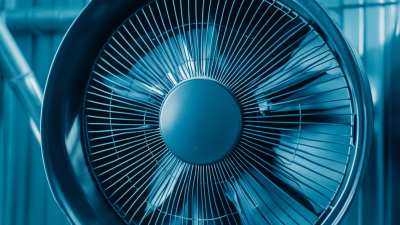

When it comes to different types of Heat Exchangers, finding a reliable factory can make all the difference in your procurement process. At our facilities in China, we specialize in manufacturing high-quality heat exchangers tailored to meet various industrial needs. With years of experience, we take pride in our innovative designs and efficient production methods, Our range includes shell-and-tube, plate, and air-cooled heat exchangers, all built with top-notch materials to ensure durability and performance. Partnering with Ningbo Senjun New Materials Co., Ltd. means you get access to cutting-edge technology and a dedicated team committed to customer satisfaction, Whether you’re a small factory or a large manufacturer, we understand your pressure for cost-effective solutions without compromising quality. Let’s connect and explore how our products can enhance your operations while ensuring that your required specifications are met. Your business deserves the best, and we are here to deliver!

Practical Methods To Different Types Of Heat Exchanger Factory Guarantees Peak Performance For the Current Year

When it comes to optimizing efficiency and performance in various cooling and heating applications, heat exchangers play a critical role. At Ningbo Senjun New Materials Co., Ltd., we have spent over a decade mastering the art of producing high-quality wire tube condensers and copper aluminum fin heat exchangers. Our expertise spans across essential appliances such as refrigerators, freezers, drinking fountains, and display cabinets. In today's competitive market, ensuring that our products deliver peak performance year-round is paramount. To guarantee optimal efficiency, we employ a range of practical methods in our manufacturing processes. First, we focus on utilizing premium materials sourced from reliable suppliers, ensuring durability and enhanced thermal conductivity. Second, our state-of-the-art production techniques incorporate rigorous quality control measures at every stage—from design to assembly. This ensures that each heat exchanger not only meets but exceeds international standards. Furthermore, regular maintenance and performance evaluations are advocated for our customers, empowering them to optimize their systems effectively. With our commitment to excellence and customer satisfaction, Ningbo Senjun New Materials Co., Ltd. remains a trusted partner for global procurement needs. As we continue to innovate and improve our offerings, we invite businesses worldwide to explore how our heat exchangers can enhance their operations and contribute to sustainability goals. Your search for reliable and efficient thermal management solutions begins with us, ensuring your systems perform at their best throughout the year.

Practical Methods To Different Types Of Heat Exchanger Factory Guarantees Peak Performance For the Current Year

| Heat Exchanger Type | Efficiency (%) | Maintenance Frequency (months) | Average Lifespan (years) | Recommended Cleaning Method |

|---|---|---|---|---|

| Shell and Tube | 85 | 6 | 20 | Chemical Cleaning |

| Plate | 90 | 12 | 15 | High-Pressure Water Jetting |

| Air Cooled | 80 | 9 | 25 | Dry Cleaning |

| Fin Fan | 88 | 10 | 30 | Vacuum Cleaning |

| Spiral | 82 | 15 | 20 | Steam Cleaning |

Uncovering Different Types Of Heat Exchanger Factory Industry Giant Where Innovation Meets 2025

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

L

Lucas Phillips

Impressive craftsmanship! The customer service team is knowledgeable and always willing to help.

26 May 2025

L

Lucas Hall

This product is fantastic! Their support team is responsive and genuinely cares about customer satisfaction.

13 June 2025

L

Lily Carter

Incredible quality with a flawless design! The after-sales team was very supportive and attentive.

16 May 2025