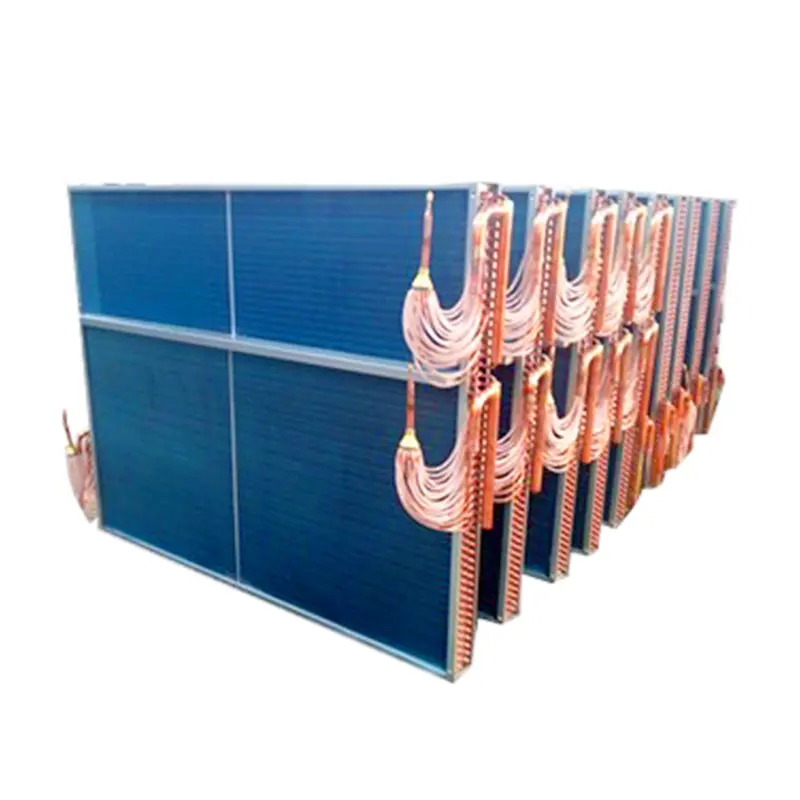

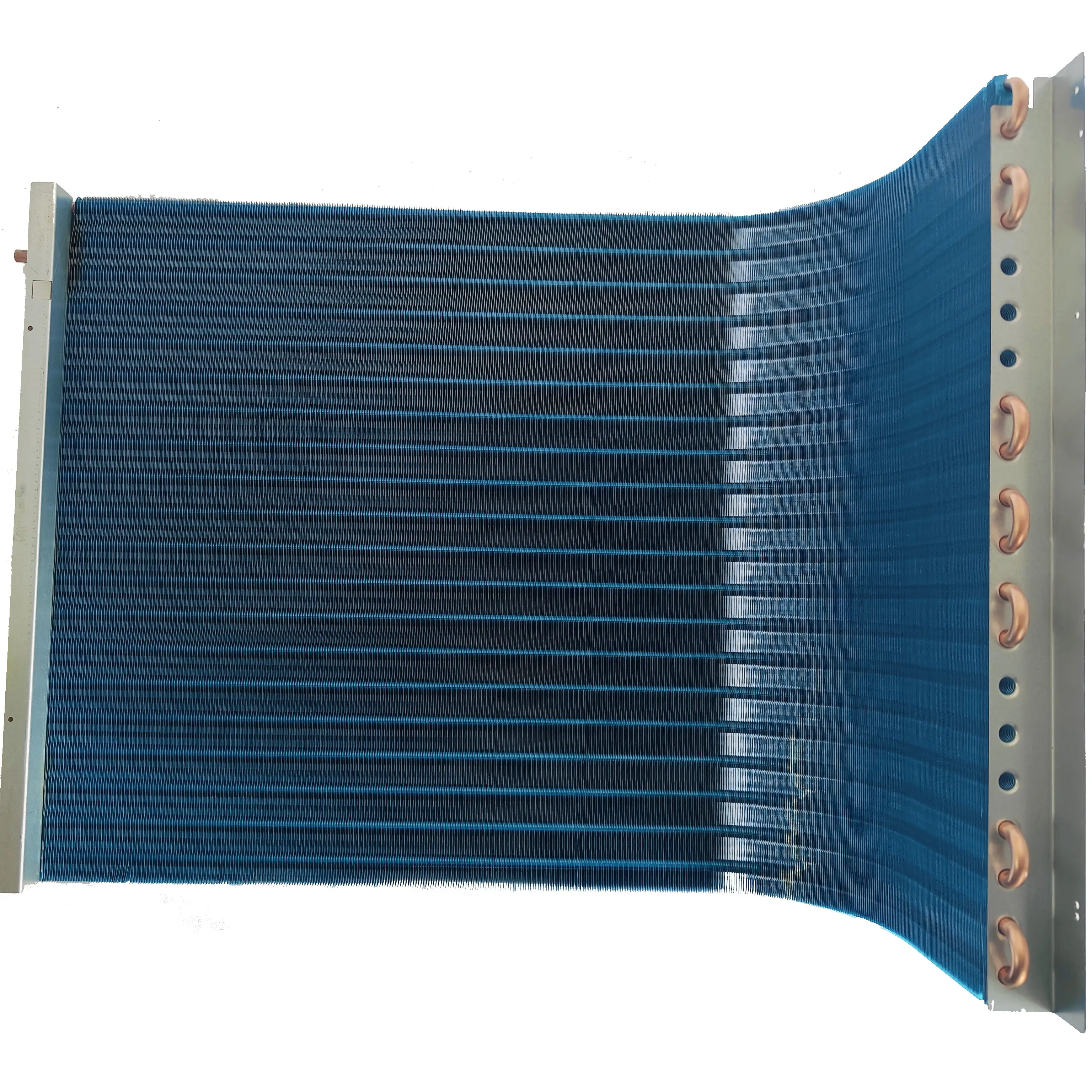

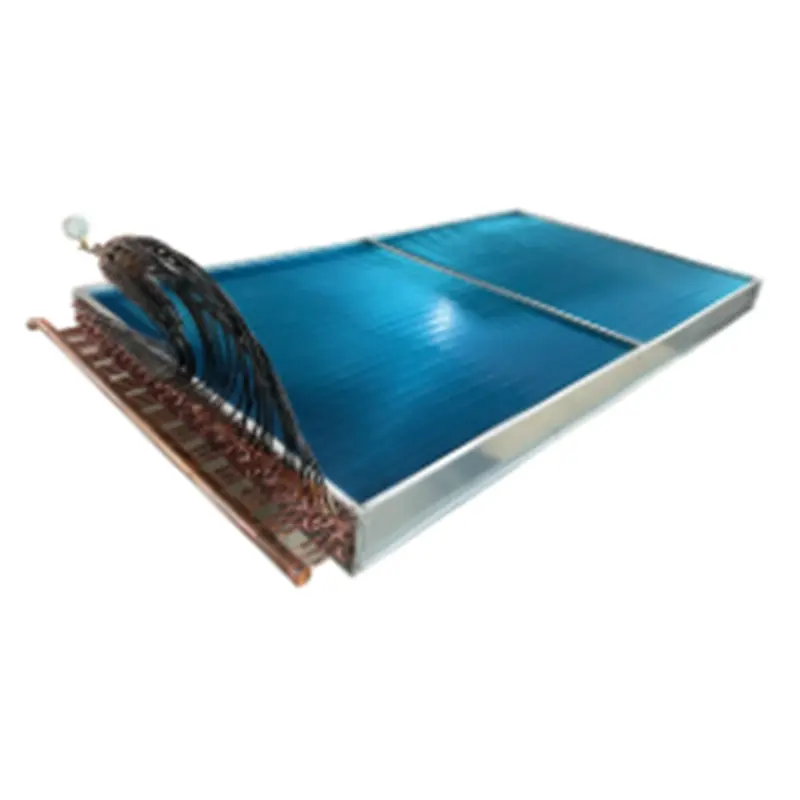

Top China Deaerating Air-Cooled Condenser Factories & Suppliers

When searching for high-quality Deaerating Air-Cooled Condenser Factories, you want a reliable partner that delivers on performance and efficiency. Our products, crafted by experienced hands in China, stand out in the market. With a strong focus on engineering precision, we ensure our condensers meet the unique needs of our clients. As a trusted manufacturer and supplier, we offer tailored solutions to enhance your operations

10 Essential Tips For Deaerating Air-Cooled Condenser Factories Service Ahead of the Curve

In the competitive landscape of industrial refrigeration, optimizing service for air-cooled condenser factories is crucial for staying ahead. Ningbo Senjun New Materials Co., Ltd., a leader in the research and development of wire tube condensers and copper aluminum fin heat exchangers, understands this need deeply. Since our inception in 2010, we have focused on delivering high-quality solutions that not only enhance performance but also ensure durability in applications like refrigerators, freezers, and display cabinets. To stay ahead of the curve in this sector, it’s essential to implement effective strategies for deaeration in air-cooled condensers. Begin by regularly monitoring system performance; consistent evaluations can help detect any inefficiencies early. Proper maintenance of the condensate drainage system is also vital, as trapped air can impede performance and lead to potential failure. Furthermore, investing in advanced monitoring technologies can provide real-time data and analytics, allowing for proactive adjustments. By adopting these essential tips, procurement professionals globally can enhance the operational efficiency of their cooling systems, ensuring that their equipment runs smoothly and extends its lifespan. At Ningbo Senjun, our commitment to innovation and quality in heat exchanger technology empowers businesses to meet their refrigeration needs while achieving substantial energy savings and operational reliability. Partner with us to leverage our expertise and enhance your service capabilities in air-cooled condenser application.

10 Essential Tips For Deaerating Air-Cooled Condenser Factories Service Ahead of the Curve

| Tip Number | Tip | Description | Frequency |

|---|---|---|---|

| 1 | Regular Inspection | Conduct thorough checks of all condenser components. | Monthly |

| 2 | Cleaning Routines | Clean the coils and fins regularly to enhance airflow. | Quarterly |

| 3 | Monitor Performance | Keep an eye on operating temperatures and pressures. | Weekly |

| 4 | Check Water Levels | Ensure optimal water levels to prevent overheating. | Daily |

| 5 | Inspect Valves | Check and replace faulty valves as necessary. | Monthly |

| 6 | Corrosion Control | Apply anti-corrosion measures on exposed surfaces. | Annually |

| 7 | System Calibration | Calibrate sensors and control systems for accuracy. | Semi-Annually |

| 8 | Documentation | Maintain detailed records of all maintenance activities. | Ongoing |

| 9 | Training Staff | Ensure all staff are trained on proper maintenance protocols. | Annually |

| 10 | Emergency Protocols | Establish clear emergency procedures for system failures. | As Needed |

Must-Know Tips For Deaerating Air-Cooled Condenser Factories Now Trending Outperforms the Competition

C

Chloe King

I’m very pleased with this product! The quality is exceptional, and the after-sales service was outstanding.

16 May 2025

H

Henry Reyes

Superb quality and excellent customer support! The team was very accommodating and knowledgeable.

18 May 2025

M

Mia Foster

Outstanding quality! The customer service representatives were extremely professional and attentive.

06 July 2025

E

Ella Hernandez

Absolutely wonderful quality! The support team was approachable and very helpful throughout.

08 June 2025

O

Olivia Moore

Very pleased with my purchase! The product quality is great, and the customer service was exemplary.

09 June 2025

L

Lucas Turner

What a great product! Quality is outstanding, and the customer service was very professional.

06 June 2025