China Suppliers for Copper Tube for Heat Exchanger - Factory Direct

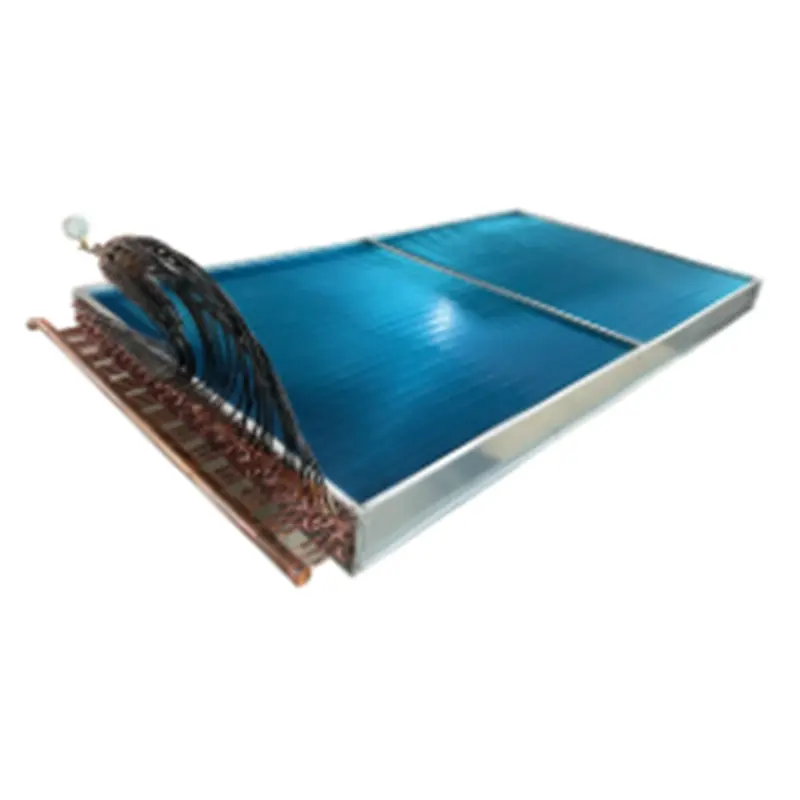

Ningbo Senjun New Materials Co., Ltd. specializes in high-quality copper tubes designed specifically for heat exchangers. Our copper tubes are engineered to deliver exceptional thermal conductivity, ensuring efficient Heat Transfer in various applications. With rigorous quality control and state-of-the-art manufacturing processes, we provide products that meet international standards and customer expectations, The versatility of our copper tubes makes them suitable for a wide range of industries, including HVAC, refrigeration, and automotive. Our commitment to innovation and sustainability ensures that our products not only perform at an optimal level but also contribute to energy savings, Available in a variety of sizes and configurations, each copper tube is crafted to facilitate easy installation and reliable operation. With years of expertise and a focus on customer satisfaction, Ningbo Senjun New Materials Co., Ltd. is your trusted partner for all your heat exchanger needs. Experience superior performance and durability with our premium copper tubes

How To Decide Between Copper Tube For Heat Exchanger Industry Giant Winning in 2025

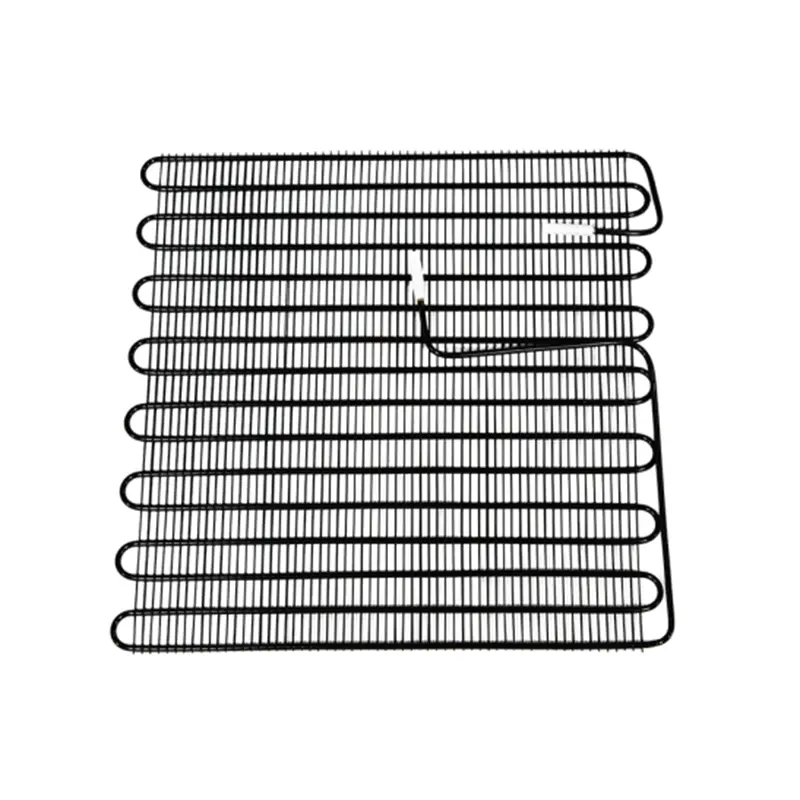

In the competitive landscape of the heat exchanger industry, choosing between different copper tube options can significantly influence product quality and operational efficiency. As one of the leading manufacturers, Ningbo Senjun New Materials Co., Ltd. specializes in producing high-performance wire tube condensers and copper-aluminum fin heat exchangers. Our experience since 2010 has taught us that selecting the right copper tube is critical for applications in refrigerators, freezers, drinking fountains, and display cabinets. When deciding on copper tubes for heat exchangers, consider the thermal conductivity, corrosion resistance, and mechanical properties. High-quality copper tubes enhance thermal exchange efficiency, which is crucial for energy-saving and maintaining optimal performance in cooling systems. Our advanced manufacturing processes ensure that our copper tubes meet stringent quality standards, offering durability and superior performance for global buyers. As we move toward 2025, the trend toward sustainable practices and energy efficiency will become paramount. Choosing the right copper tube is not just a matter of application; it’s about aligning with environmental goals. At Ningbo Senjun, we are committed to innovation and sustainability, ensuring our products are not only effective but also contribute to a greener future. By partnering with us, global purchasers can rest assured that they are making informed choices that set their businesses up for success in a rapidly evolving industry.

How To Decide Between Copper Tube For Heat Exchanger Industry Giant Winning in 2025

| Property | Copper Tube Type A | Copper Tube Type B | Copper Tube Type C |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 398 | 385 | 400 |

| Corrosion Resistance (Standard) | High | Medium | High |

| Weight (kg/m) | 0.75 | 0.80 | 0.70 |

| Cost per Meter (USD) | 3.50 | 4.00 | 3.75 |

| Maximum Operating Temperature (°C) | 150 | 120 | 160 |

Making Smart Choices Copper Tube For Heat Exchanger Stands Out Industry Giant

I

Isabella White

This product is worth every penny! The quality is impressive, and the customer service team provided excellent support.

17 May 2025

C

Chloe King

I’m very pleased with this product! The quality is exceptional, and the after-sales service was outstanding.

16 May 2025

O

Olivia White

Very high quality. The support team was quick to assist and very knowledgeable.

26 May 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

C

Chloe Cooper

Very high quality with exceptional support! The after-sales team truly cares about their customers.

08 June 2025

E

Ethan Taylor

Fantastic durability and quality! The after-sales team was extremely professional and insightful.

08 June 2025