Wholesale Copper Fittings for Refrigeration Tubing | Supplier & Manufacturer

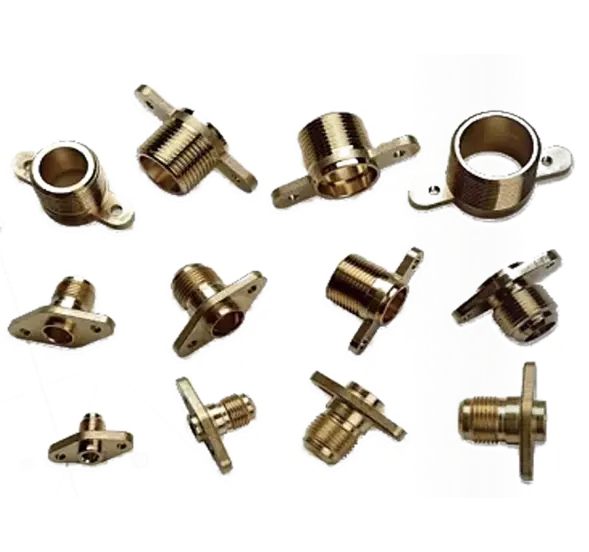

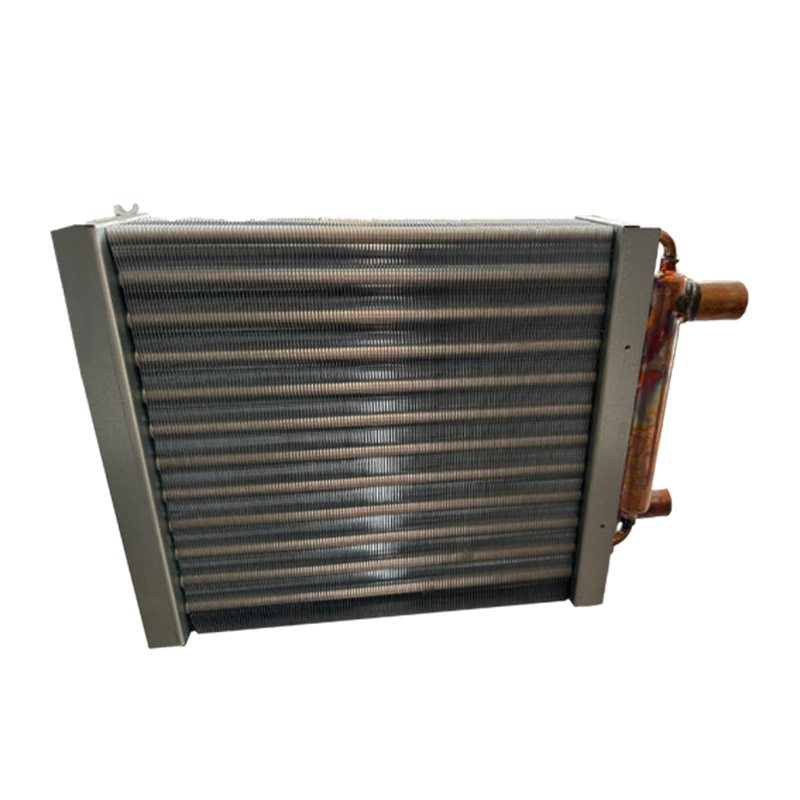

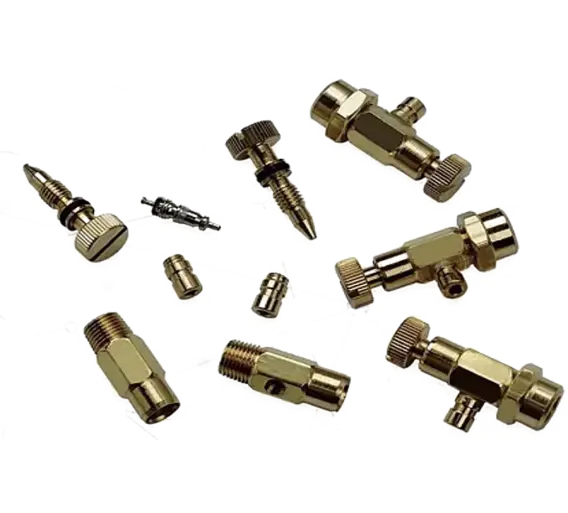

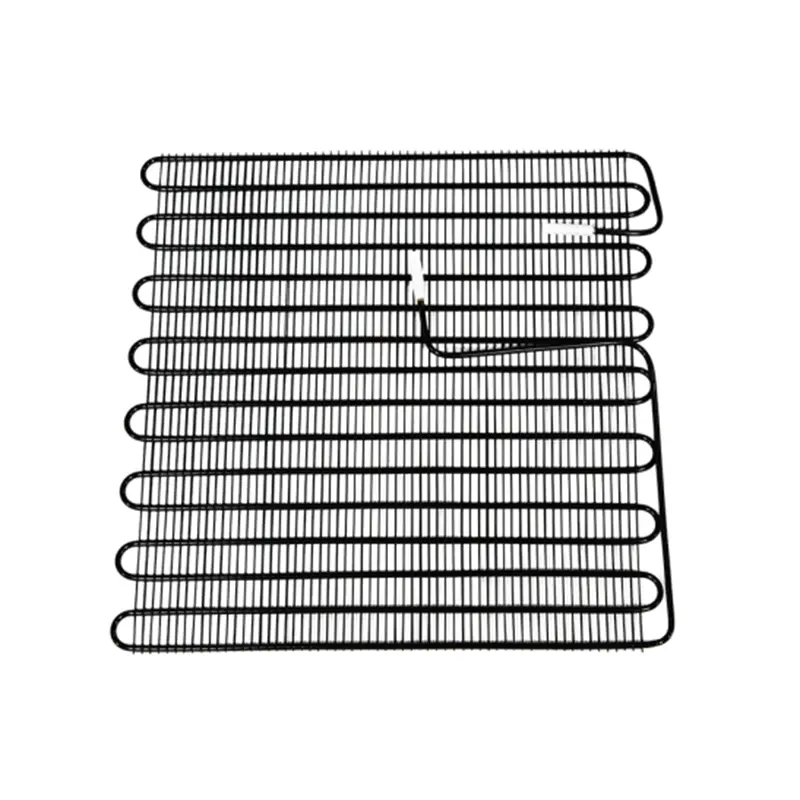

Ningbo Senjun New Materials Co., Ltd. offers high-quality copper fittings specifically designed for refrigeration tubing applications. Crafted with precision and durability in mind, our copper fittings ensure optimal performance in HVAC systems and refrigeration units. Made from premium-grade copper, these fittings are resistant to corrosion and provide excellent thermal conductivity, making them ideal for efficient refrigerant flow, Our extensive range includes elbows, tees, couplings, and adapters, all available in various sizes to meet diverse installation requirements. With a focus on safety and reliability, each fitting undergoes rigorous testing to ensure compliance with industry standards, Choose Ningbo Senjun for your refrigeration needs, where innovation meets quality. Our commitment to excellence guarantees that every product enhances the efficiency and longevity of your refrigeration systems. Trust us to deliver the right solutions for your projects, backed by exceptional customer service and support. Enhance your installations with our reliable copper fittings today!

Quick Tips To Copper Fittings For Refrigeration Tubing Custom Solutions, Industry Giant

When it comes to optimizing refrigeration systems, the importance of high-quality copper fittings can't be overstated. At Ningbo Senjun New Materials Co., Ltd., we specialize in tailored solutions for wire tube condensers and copper-aluminum fin heat exchangers, serving diverse applications such as refrigerators, freezers, drinking fountains, and display cabinets. Our expertise since 2010 focuses on blending innovation with practicality, ensuring that our custom copper fittings enhance performance and efficiency in refrigeration tubing. For global buyers, understanding the specific requirements for copper fittings in refrigeration is crucial. Factors such as temperature regulation, pressure tolerance, and corrosion resistance play significant roles in the choice of materials. In addressing these needs, our team leverages advanced technology and research, allowing us to provide effective solutions that meet the varying demands of industries worldwide. Choosing the right fittings can significantly impact energy efficiency, prolong equipment lifespan, and reduce maintenance costs, making our products a smart investment for any refrigeration system. By partnering with Ningbo Senjun, you're not just getting high-quality copper fittings; you're gaining a dedicated team committed to your success. Our focus on customization means we can adapt our products to suit your specific applications and operational challenges. As an industry giant, we pride ourselves on our ability to innovate and respond to market needs swiftly. Explore our range of copper fittings and discover how our solutions can streamline your refrigeration processes today.

Quick Tips To Copper Fittings For Refrigeration Tubing Custom Solutions, Industry Giant

| Tip Number | Tip Description | Material Type | Application | Recommended Size (inches) |

|---|---|---|---|---|

| 1 | Ensure proper cleaning before soldering. | Copper | Refrigeration systems | 1/2 |

| 2 | Use a flux that is appropriate for refrigeration applications. | Copper | HVAC systems | 3/4 |

| 3 | Check for compatibility with refrigerants. | Copper-Nickel | Marine applications | 1 |

| 4 | Select the right fittings for angle and space constraints. | Copper | Residential and commercial refrigeration | 5/8 |

| 5 | Regularly inspect for corrosion and wear. | Copper | Maintenance of cooling systems | 1-1/8 |

Popular Copper Fittings For Refrigeration Tubing in 2025 Factory-Direct Excellence

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

M

Mia Howard

Unbelievable quality! The customer service team went the extra mile to ensure my satisfaction.

24 May 2025

J

James Adams

A product that truly stands out! Quality is superb and the customer service team is highly professional.

04 July 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

E

Ella Hernandez

Absolutely wonderful quality! The support team was approachable and very helpful throughout.

08 June 2025

J

Joshua Campbell

Fantastic craftsmanship! The after-sales service was prompt and the staff was very competent.

08 May 2025