Top China Copper Coil Fin Condenser Manufacturers for Quality Solutions

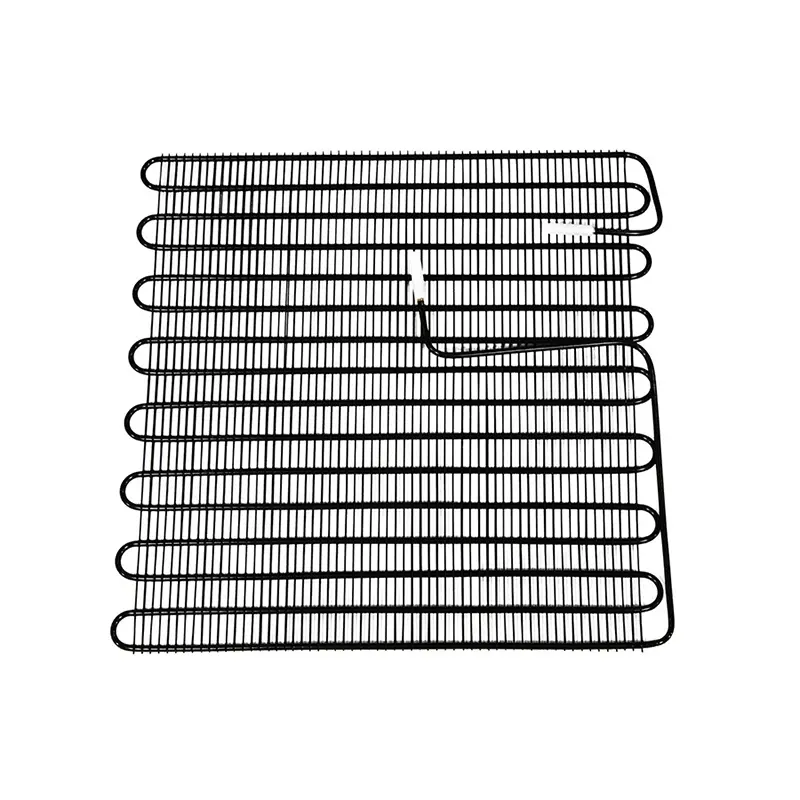

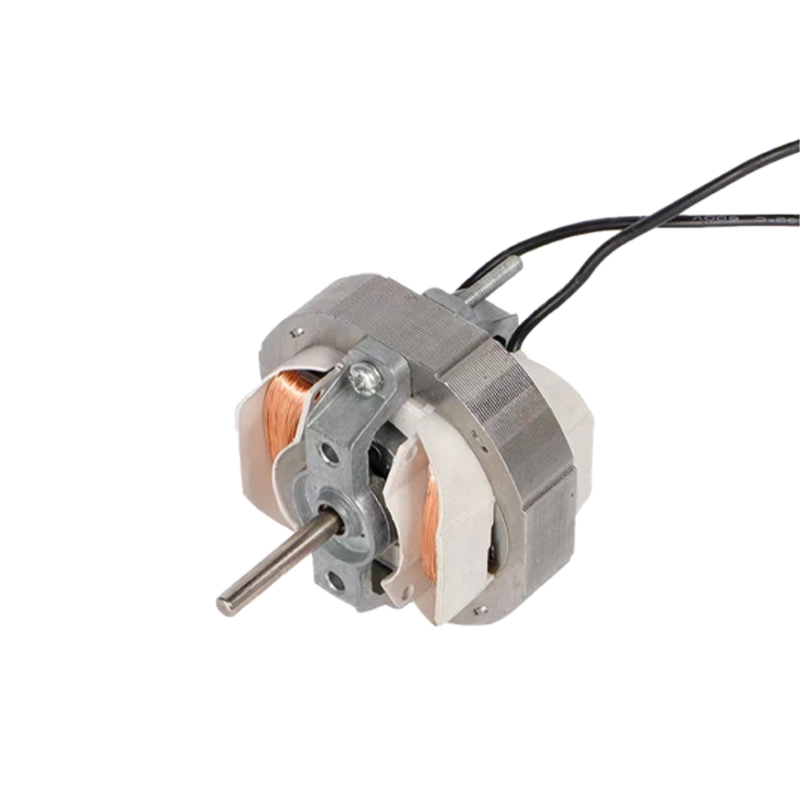

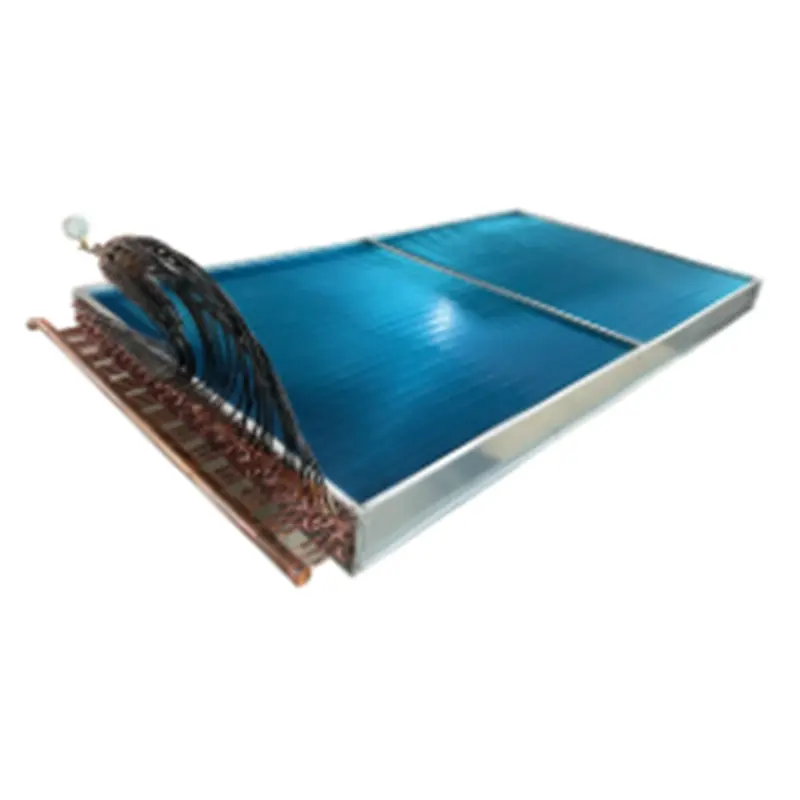

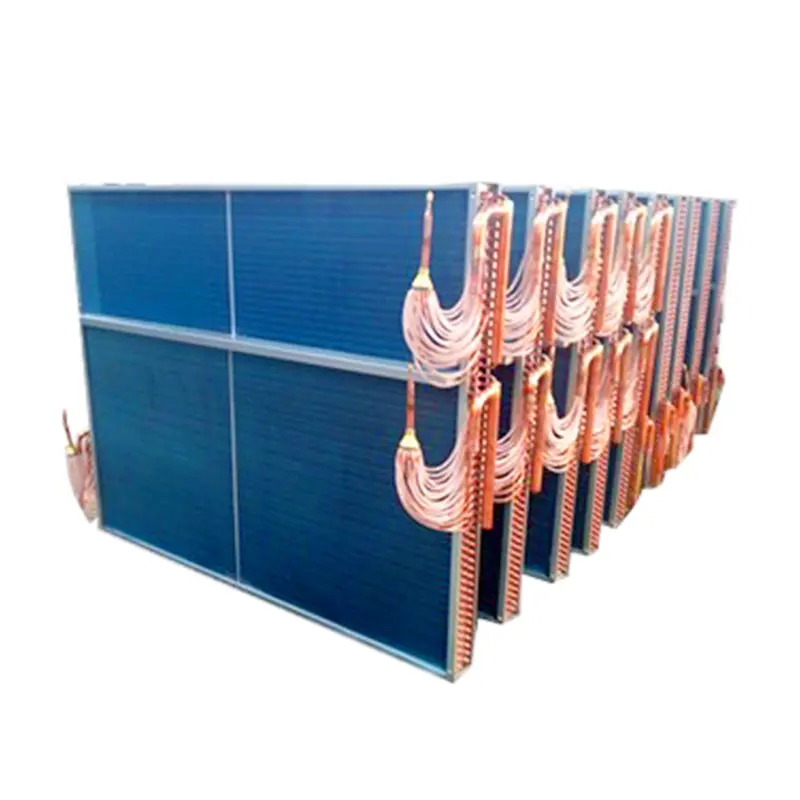

Ningbo Senjun New Materials Co., Ltd. proudly presents our high-performance Copper Coil Fin Condenser, designed to meet the demanding needs of modern HVAC Systems. With a commitment to quality and innovation, our condensers feature superior heat exchange capabilities, optimizing energy efficiency in both residential and commercial applications, Engineered from premium copper materials, the coils ensure excellent thermal conductivity and corrosion resistance, promoting a longer service life. The fin design enhances surface area, significantly improving heat dissipation and resulting in better cooling performance, Our Copper Coil Fin Condensers are customizable to fit a variety of system configurations, making them ideal for various installations. Rigorous testing guarantees reliable performance under diverse operating conditions, giving you peace of mind, Choose Ningbo Senjun New Materials Co., Ltd. for advanced solutions that combine durability, efficiency, and innovation. Elevate your cooling system with our state-of-the-art condensers, crafted to deliver exceptional results while minimizing energy consumption. Discover the future of HVAC technology today!

Trending Copper Coil Fin Condenser Outperforms the Competition Industry Leaders

In today's competitive markets, the demand for efficient and high-performance heat exchangers is on the rise, particularly in the refrigeration industry. At Ningbo Senjun New Materials Co., Ltd., established in 2010, we have dedicated ourselves to the innovation and production of advanced wire tube condensers and copper-aluminum fin heat exchangers. Our latest offering, the trending copper coil fin condenser, stands out as a superior choice that outperforms the competition, positioning itself firmly among industry leaders. Our copper coil fin condensers are engineered for optimal thermal performance, ensuring rapid heat dissipation and energy efficiency. The innovative design incorporates high-quality materials that enhance durability and reduce maintenance costs, a crucial consideration for global buyers. With applications across various sectors—such as refrigerators, freezers, drinking fountains, and display cabinets—our products meet the diverse needs of our clients, delivering reliable and effective solutions that contribute to their operational success. What sets us apart in the market is not only our commitment to quality but also our focus on customer-centric development. We actively invest in research and development, ensuring that our products continuously evolve with the latest technological advancements. By partnering with Ningbo Senjun New Materials Co., Ltd., you gain access to superior products that not only meet but exceed industry standards, empowering your business to thrive in a fast-paced environment. Discover the difference of our trending copper coil fin condenser and experience a new level of performance in your refrigeration applications.

Trending Copper Coil Fin Condenser Outperforms the Competition Industry Leaders

| Model | Cooling Capacity (BTU/hr) | Energy Efficiency Ratio (EER) | Operational Noise (dB) | Warranty (Years) |

|---|---|---|---|---|

| Model A | 18,000 | 12.5 | 48 | 5 |

| Model B | 16,000 | 11.8 | 50 | 4 |

| Model C | 20,000 | 13.0 | 45 | 6 |

| Model D | 22,000 | 14.2 | 44 | 6 |

Decoding Copper Coil Fin Condenser Delivers Unmatched Quality Application

R

Ryan Turner

I’m very satisfied! The item quality is great, and the after-sales service was attentive and professional.

23 June 2025

G

Grace Hall

Truly delighted with my purchase. The quality is outstanding, and the after-sales service exceeded my expectations.

30 May 2025

G

Gabriel Washington

The product quality is outstanding. The after-sales team was impressive, very knowledgeable, and easy to work with.

06 June 2025

R

Ryan Clark

Great product! The quality is unmatched, and the after-sales service was incredibly supportive.

18 May 2025

H

Henry Martinez

Exceptional product quality! The customer service team went above and beyond to assist me.

27 June 2025

A

Avery Baker

Superb product quality and excellent customer service! The support staff was very knowledgeable.

05 July 2025