Wholesale Condensing Heat Exchanger for Steam | Factory Manufacturers

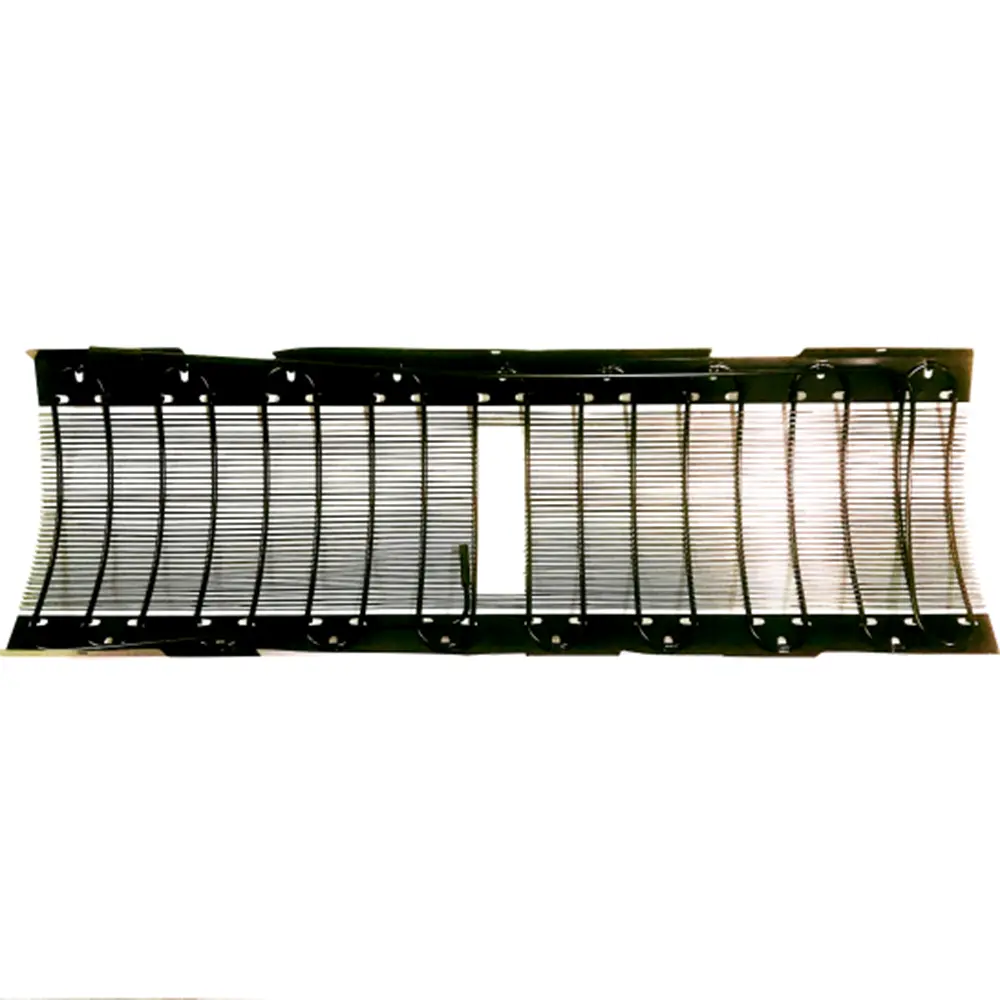

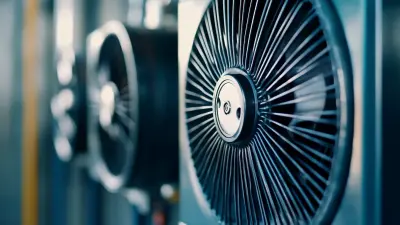

Ningbo Senjun New Materials Co., Ltd. proudly presents its state-of-the-art Condensing Heat Exchanger, designed to optimize energy efficiency in various industrial applications. This advanced equipment maximizes heat recovery by efficiently converting steam back into water, significantly reducing energy consumption and operational costs, Constructed using high-quality materials, our heat exchanger boasts exceptional durability and performance, even in the most demanding environments. The compact design ensures easy integration into existing systems, while its innovative engineering allows for superior Heat Transfer efficiency, Ideal for power generation, chemical processing, and HVAC systems, the Condensing Heat Exchanger is not only environmentally friendly but also aligns with today’s sustainability goals. With a focus on precision and reliability, Ningbo Senjun New Materials Co., Ltd. is committed to providing solutions that enhance productivity and reduce environmental impact. Trust our expertise to deliver top-notch products that meet your heating and cooling needs

Tips & Tricks for Condensing Heat Exchanger For Steam Market Leader Ahead of the Curve

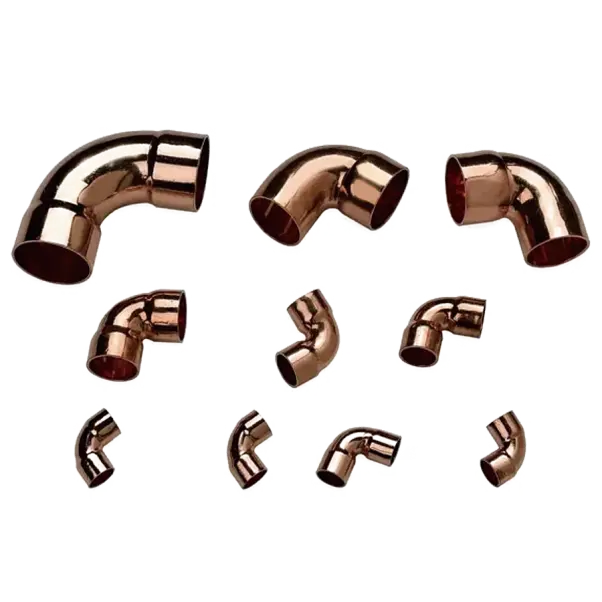

In today's rapidly evolving market, staying ahead requires innovative solutions and a deep understanding of industry dynamics. As a leader in providing high-quality wire tube condensers and copper-aluminum fin heat exchangers, Ningbo Senjun New Materials Co., Ltd. offers invaluable tips and tricks for global buyers looking to optimize their steam heat exchanger needs. Firstly, understanding the specific requirements of your applications—such as load capacity and temperature ranges—is essential. Customizing your heat exchanger design not only enhances performance but also improves energy efficiency and reduces operational costs. Our products are designed to meet the rigorous demands of refrigerators, freezers, drinking fountains, and display cabinets, ensuring they excel in various environments. Moreover, choosing the right materials can significantly impact durability and efficiency. Our advanced technologies in materials research and production empower clients to achieve optimal thermal conductivity while minimizing environmental impact. By partnering with Ningbo Senjun, global buyers can gain access to cutting-edge technology and expertise that keep you ahead in the competitive market landscape. Embrace these strategies to enhance your operational efficiency and solidify your position as a market leader.

Tips & Tricks for Condensing Heat Exchanger For Steam Market Leader Ahead of the Curve

| Tip/Trick | Description | Expected Benefit | Implementation Ease |

|---|---|---|---|

| Optimize Tube Layout | Redesign the tube arrangement to improve fluid dynamics. | Increased heat transfer efficiency by up to 15%. | Moderate |

| Enhance Insulation | Upgrade insulation materials to minimize heat loss. | Reduce energy costs by up to 10%. | Easy |

| Regular Maintenance Checks | Schedule routine inspections and cleanings. | Prevents inefficiencies and extends lifespan. | Easy |

| Utilize Variable Frequency Drives | Install VFDs for pumps and fans to optimize performance. | Potential energy savings of 20%. | Moderate |

| Implement Predictive Maintenance | Use sensors to predict failures before they occur. | Reduces downtime and maintenance costs. | Difficult |

Best Way To Choose Condensing Heat Exchanger For Steam Trusted by Pros Is The Best

J

Jessica Patel

The quality of the item is remarkable! Plus, the customer service was so professional and helpful throughout the entire process.

05 July 2025

D

Daniel Clark

High-quality product with an impressive finish. The support team was very knowledgeable and addressed my concerns promptly.

16 June 2025

J

Jack Adams

This is a product of high quality. The after-sales service team was very knowledgeable and assisted me effectively.

26 June 2025

S

Samuel Carter

I can’t get over the quality! The customer service team was incredibly professional and responsive.

17 May 2025

S

Sebastian Jenkins

Excellent product! The customer support staff were highly professional and very helpful.

09 June 2025

H

Henry Martinez

Exceptional product quality! The customer service team went above and beyond to assist me.

27 June 2025