Top China Manufacturers & Suppliers of Condenser in Chiller Systems

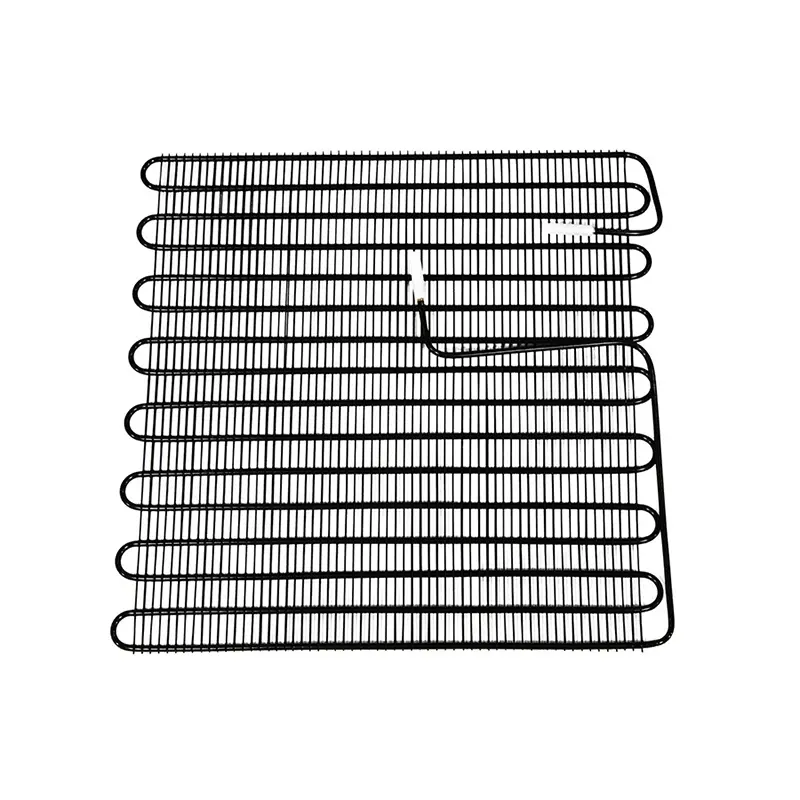

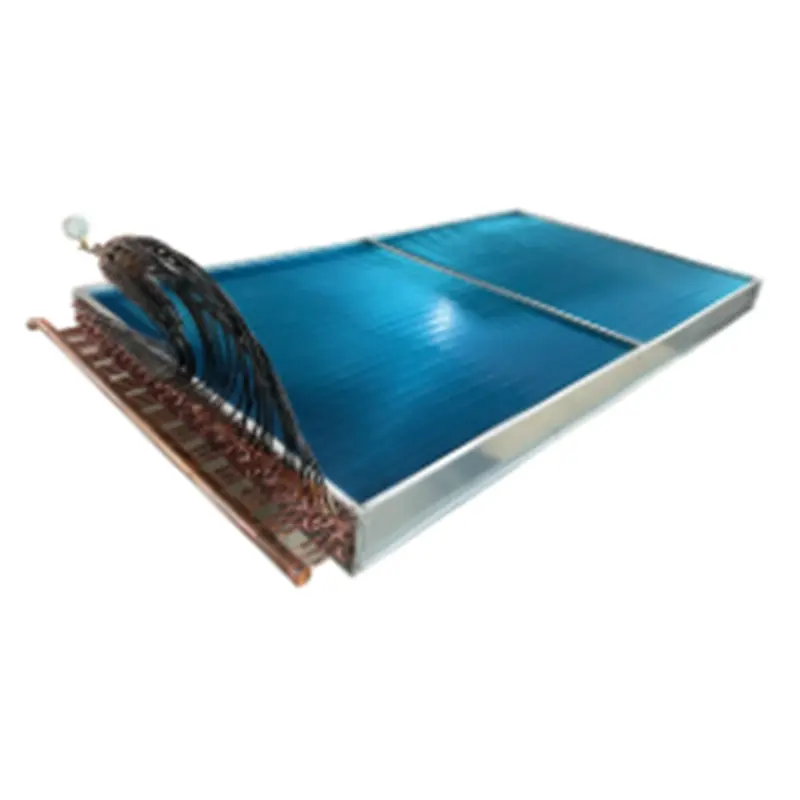

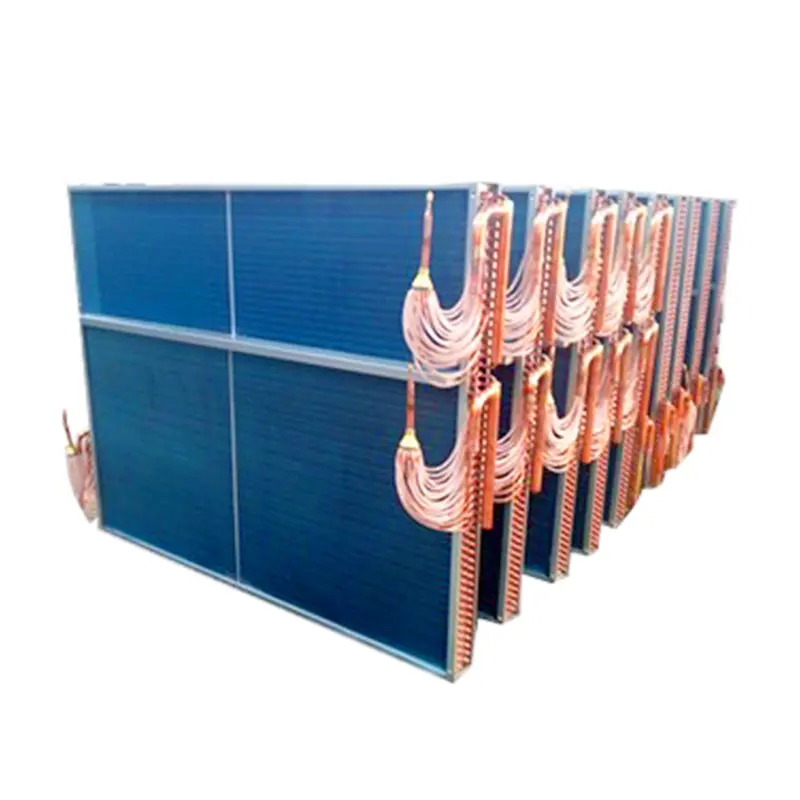

Ningbo Senjun New Materials Co., Ltd. proudly presents its advanced condenser solutions designed specifically for chillers. Our condensers are engineered to optimize cooling efficiency and reliability, catering to both commercial and industrial applications. Utilizing cutting-edge materials and innovative construction techniques, these condensers ensure maximum heat exchange and energy savings, making them a vital component for any chiller system, With a focus on durability and performance, our condensers are resistant to corrosion and high-pressure environments, allowing for longer operational life and minimal maintenance. Each unit is rigorously tested to meet international quality standards, ensuring top-tier performance and reliability, Whether you’re upgrading existing equipment or designing new systems, our condensers provide the perfect balance of efficiency and cost-effectiveness. Choose Ningbo Senjun New Materials Co., Ltd. for unparalleled quality and service in your chiller applications. Experience the difference with our state-of-the-art condenser technology designed for the future of cooling solutions

Why Trust Condenser In Chiller Guarantees Peak Performance Your End-to-End Solution

In the competitive landscape of industrial cooling solutions, ensuring peak performance and reliability is essential. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on our extensive expertise in producing high-quality wire tube condensers and copper-aluminum fin heat exchangers for a variety of applications, including refrigerators, freezers, drinking fountains, and display cabinets. Founded in 2010, our commitment to research and development has enabled us to deliver innovative products that meet the stringent demands of global customers. One of the key factors influencing the efficiency and longevity of cooling systems is the condenser. Our condensers are meticulously designed to optimize heat exchange, minimizing energy consumption while maximizing cooling performance. By choosing our products, procurement managers and decision-makers can trust that they are investing in cutting-edge technology that guarantees reliable operation, reduces downtime, and enhances the overall efficiency of their cooling systems. Moreover, we understand the importance of providing an end-to-end solution to our clients. From the initial design phase to production and after-sales support, our dedicated team works closely with customers to address their unique requirements. By collaborating with us, buyers can improve their operational performance and gain a competitive edge in their markets. Trusting Ningbo Senjun means committing to a partnership focused on quality, innovation, and continuous improvement.

Why Trust Condenser In Chiller Guarantees Peak Performance Your End-to-End Solution

| Parameter | Value | Description |

|---|---|---|

| Cooling Capacity | 500 kW | The maximum cooling power output of the chiller. |

| Energy Efficiency Ratio (EER) | 3.5 | Measurement of cooling output divided by energy consumption. |

| Refrigerant Type | R-410A | Type of refrigerant used in the cooling process. |

| Operating Temperature Range | -10 to 45 °C | The temperature limits for optimal chiller operation. |

| Condensing Pressure | 200 psi | Pressure at which refrigerant gas condenses into a liquid. |

| Warranty Period | 5 years | Duration of warranty coverage for the chiller unit. |

Finding Your Perfect Match Condenser In Chiller Where Service Meets Innovation Manufacturers You Can Rely On

J

Jack Adams

This is a product of high quality. The after-sales service team was very knowledgeable and assisted me effectively.

26 June 2025

M

Mia Howard

Unbelievable quality! The customer service team went the extra mile to ensure my satisfaction.

24 May 2025

E

Ethan Fisher

Impressive quality! The after-sales support team was attentive and provided great service.

15 June 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

A

Avery Baker

Superb product quality and excellent customer service! The support staff was very knowledgeable.

05 July 2025

E

Ethan Gonzalez

Very high quality and attentive service! The after-sales team is exceptionally professional.

12 June 2025