China Condenser Coil Manufacturer & Supplier for Air Conditioners

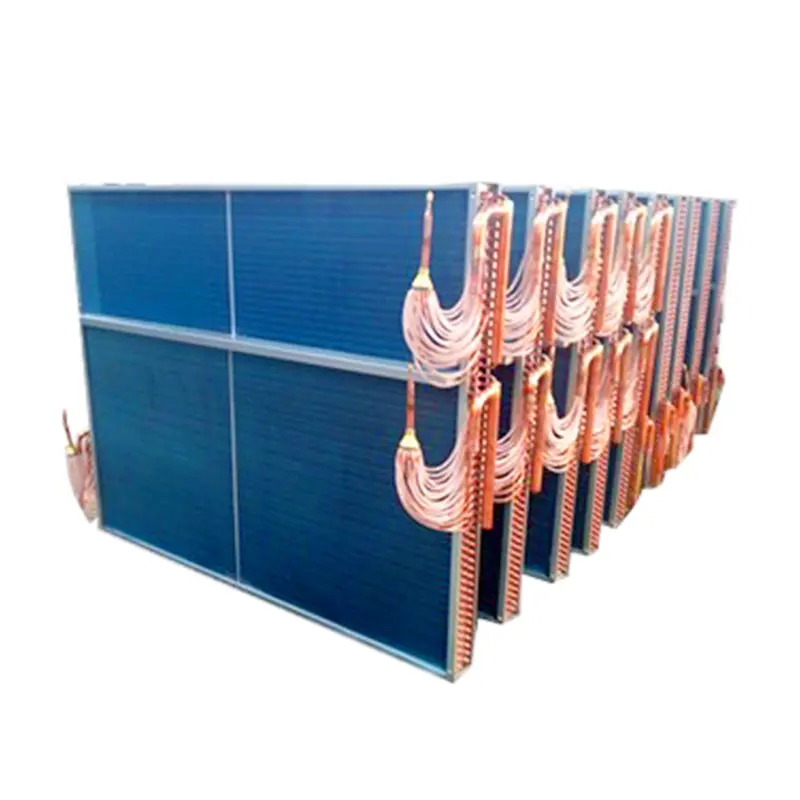

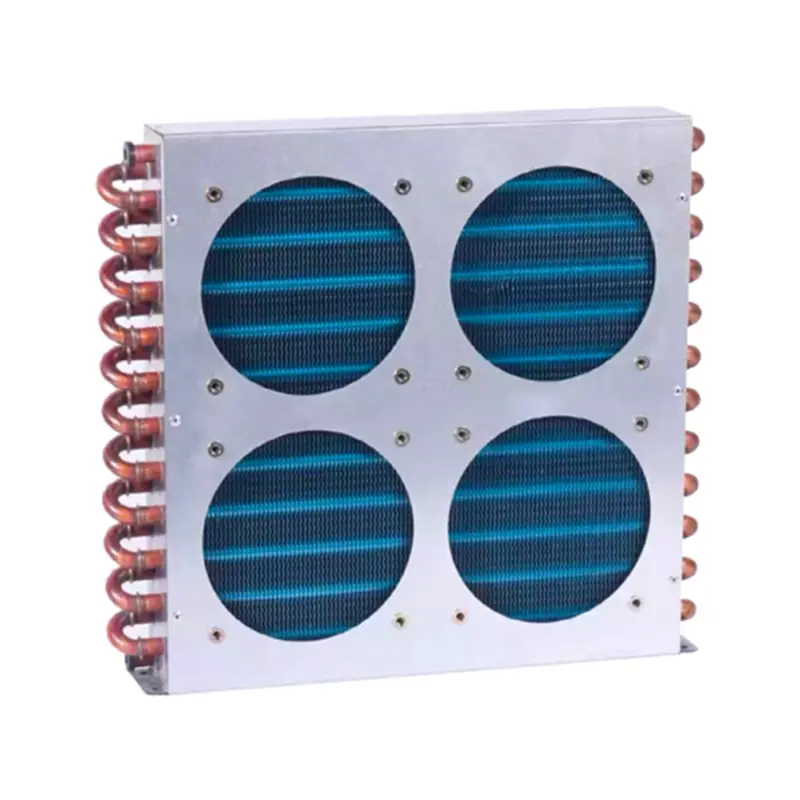

When it comes to sourcing high-quality condenser coils for air conditioners, I turn to reliable factories in China. At Ningbo Senjun New Materials Co., Ltd., we specialize in manufacturing durable and Efficient Condenser coils that meet the demands of today's HVAC market. Our expert team uses advanced technology and premium materials to ensure that each coil is built to last, optimizing performance and energy efficiency for your air conditioning systems, We understand the importance of reliability in your supply chain, which is why our manufacturing processes adhere to strict quality standards. Partnering with us means you can expect timely delivery and responsive customer service tailored to your needs. Whether you're a small business or a large-scale manufacturer, we're here to support your projects. Choose us as your trusted manufacturer for condenser coils, and experience the difference in quality and performance

Methods To choose Condenser Coil On Air Conditioner Factory Application Factory-Direct Excellence

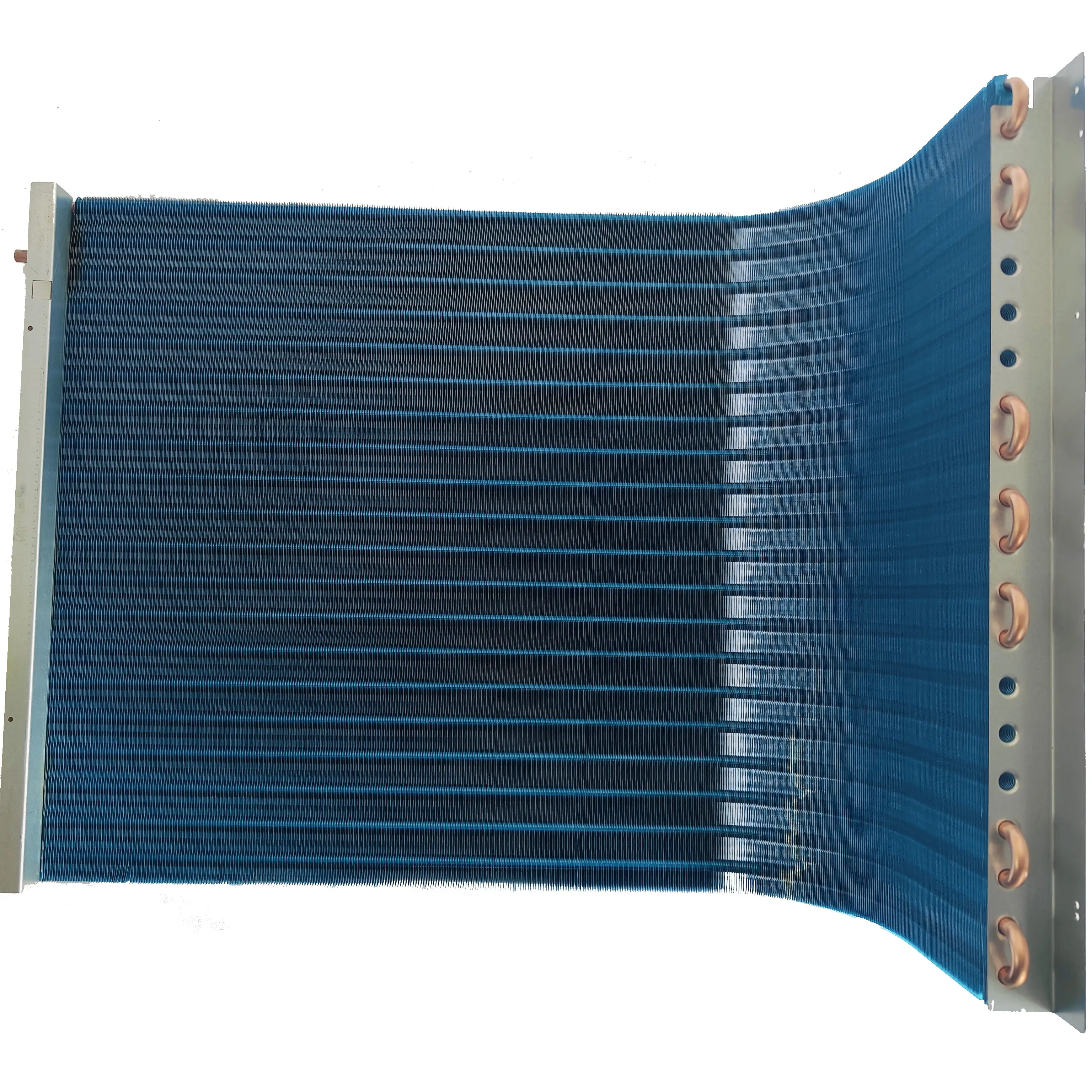

When selecting condenser coils for air conditioning applications in factory settings, manufacturers must prioritize performance and efficiency to meet the growing demands of energy conservation and sustainability. At Ningbo Senjun New Materials Co., Ltd., we understand that the choice of condenser coil can significantly impact the overall effectiveness of HVAC systems, which is why we focus on delivering high-quality wire tube condensers and copper aluminum fin heat exchangers tailored for diverse applications, including refrigerators, freezers, and display cabinets. One key method for choosing the right condenser coil is to assess the specific cooling requirements of your factory environment. Factors such as ambient temperature, humidity levels, and the type of equipment being used can influence the efficiency of heat exchange. Our expert team at Senjun collaborates closely with clients to identify the optimal specifications for their systems, ensuring the best performance. Additionally, understanding material compatibility and overall construction quality is crucial. Our condensers are designed with durability in mind, using advanced materials to withstand harsh operating conditions while providing exceptional heat exchange efficiency. Moreover, sourcing directly from our factory ensures not only competitive pricing but also a strong emphasis on product excellence. With over a decade of experience since our founding in 2010, we have honed our processes and quality control measures to guarantee that our clients receive reliable products that enhance their operational performance. In today's competitive market, making informed decisions about condenser coils can lead to significant cost savings and improved energy efficiency, setting the foundation for a sustainable future in factory applications. Connect with us to learn more about how our innovative solutions can meet your needs.

Methods To Choose Condenser Coil On Air Conditioner Factory Application Factory-Direct Excellence

| Criteria | Description | Material | Efficiency | Cost |

|---|---|---|---|---|

| Size | Dimension considerations for installation | Copper | High | $120 |

| Type of Coil | Finned tube, plate type, etc. | Aluminum | Medium | $80 |

| Cooling Capacity | Size based on BTU requirements | Copper | High | $150 |

| Environment | Indoor vs Outdoor usage | Aluminum | Medium | $90 |

| Energy Efficiency Rating | Rating systems for performance | Copper & Aluminum | Very High | $200 |

Top 5 Condenser Coil On Air Conditioner Factory From Concept to Delivery Stands Out

O

Olivia Davis

The craftsmanship of this product is top-tier. I was pleasantly surprised by the professionalism of the customer service team.

04 July 2025

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

A

Abigail Scott

Amazing product! The quality surpassed my expectations, and the support team was incredibly responsive.

25 May 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

A

Alexander Murphy

A truly wonderful experience! The quality of this product is exceptional, and the service was fast and friendly.

07 June 2025

E

Emma Watson

Overall, a great experience! The quality is impressive, and the customer service was very accommodating.

31 May 2025