Wholesale Refrigeration Plate Heat Exchanger | Supplier & Manufacturers

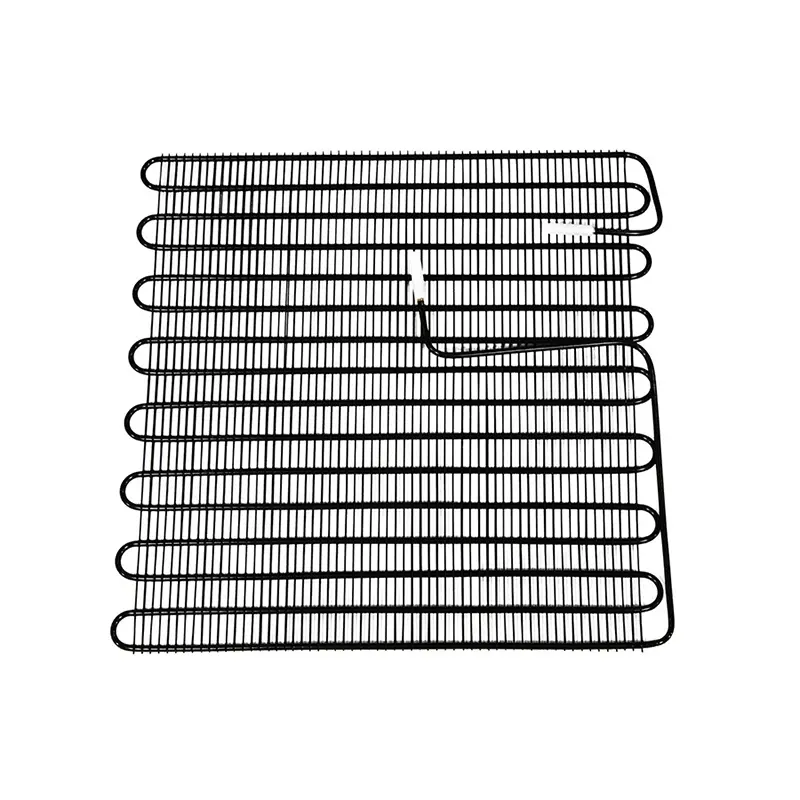

Ningbo Senjun New Materials Co., Ltd. offers state-of-the-art Refrigeration Plate Heat Exchangers designed for optimal thermal efficiency in various industrial applications. These innovative heat exchangers use a series of corrugated plates to maximize surface area, enabling superb Heat Transfer capabilities while minimizing energy consumption. Crafted from high-quality materials, our products ensure durability and resistance to corrosion, making them ideal for demanding refrigeration environments, With a compact design, these plate heat exchangers are perfect for space-constrained installations, offering significant advantages over traditional shell-and-tube exchangers. The easy maintenance and cleaning processes further enhance their usability, making them a reliable choice for both new installations and system upgrades, Our Refrigeration Plate Heat Exchangers are engineered to meet industry standards, ensuring superior performance and longevity. Trust Ningbo Senjun New Materials Co., Ltd. to provide solutions that elevate efficiency and sustainability in your refrigeration systems. Experience the perfect balance between performance and reliability with our cutting-edge technology

Ultimate Guide To Refrigeration Plate Heat Exchanger From Concept to Delivery Exceeds Industry Benchmarks

In today's competitive landscape, efficient refrigeration systems are indispensable for various applications, ranging from commercial freezers to residential refrigerators. At Ningbo Senjun New Materials Co., Ltd., we have revolutionized the production of plate heat exchangers, ensuring that our solutions not only meet but exceed industry benchmarks. Since our establishment in 2010, we have dedicated ourselves to the research and development of advanced wire tube condensers and copper aluminum fin heat exchangers, providing our global partners with cutting-edge technologies that optimize thermal performance. Our Ultimate Guide to Refrigeration Plate Heat Exchangers explores the journey from concept to delivery, highlighting how our innovative designs facilitate energy efficiency and enhance cooling capabilities. By leveraging high-quality materials and precision engineering, we create systems that are not only reliable but also adaptable to a wide range of refrigeration applications, including display cabinets and drinking fountains. Our commitment to excellence ensures that you receive products that are expertly crafted and rigorously tested to meet international standards. As a supplier that prioritizes client satisfaction, we work closely with our partners, offering customized solutions tailored to their specific needs. With a strong focus on quality and service, Ningbo Senjun New Materials Co., Ltd. stands ready to support your procurement requirements and help you achieve superior performance and reliability in your refrigeration systems. Together, let's elevate your operations with our industry-leading heat exchanger technologies!

Ultimate Guide To Refrigeration Plate Heat Exchanger From Concept to Delivery Exceeds Industry Benchmarks

| Parameter | Value | Industry Benchmark |

|---|---|---|

| Heat Transfer Efficiency | 85% | 75% |

| Pressure Drop (kPa) | 15 kPa | 25 kPa |

| Material of Construction | 316 Stainless Steel | 304 Stainless Steel |

| Operating Temperature Range | -20°C to 150°C | -10°C to 130°C |

| Maintenance Interval (Months) | 12 Months | 18 Months |

| Flow Rate (m³/h) | 10 m³/h | 8 m³/h |

How To Decide Between Refrigeration Plate Heat Exchanger Outperforms the Competition Winning in 2025

R

Rachel Green

Quality and service are both exceptional! I received prompt assistance from the support team, which made my experience even better.

28 June 2025

S

Sophia Martinez

I’m thrilled with this product! The quality is outstanding, and the customer service really goes above and beyond.

27 June 2025

A

Abigail Scott

Amazing product! The quality surpassed my expectations, and the support team was incredibly responsive.

25 May 2025

H

Henry Reyes

Superb quality and excellent customer support! The team was very accommodating and knowledgeable.

18 May 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

C

Charlotte Mitchell

This product is wonderful! The quality is high, and the customer service team excelled in their support.

17 May 2025