What Is Nano-Coating Technology & Why It’s the Future of Heat Exchangers?

I see nano-coating technology as a game-changer in the world of Heat Exchangers. This advanced process applies ultra-thin layers to surfaces. I often use it to boost efficiency, extend durability, and protect equipment like theCopper Fin Heat Exchanger from corrosion and fouling.

Key Takeaways

- Nano-coating technology applies ultra-thin layers to heat exchangers, boosting Heat Transfer efficiency by up to 50% and reducing fouling and corrosion significantly.

- These coatings extend equipment lifespan, cut maintenance costs, and save energy by keeping surfaces cleaner and improving thermal performance.

- Nano-coatings also support environmental goals by lowering energy use, reducing harmful emissions, and minimizing the need for chemical cleaning agents.

Nano-Coating Technology and Its Impact on Heat Exchangers

What Is Nano-Coating Technology?

I see nano-coating technology as a breakthrough in surface engineering. This process involves applying ultra-thin layers—often just a few nanometers thick—onto the surfaces of heat exchangers. These coatings use advanced scientific principles to create protective barriers that enhance performance and durability.

To better understand the science behind nano-coating, I often refer to the following table, which summarizes the key mechanisms and their applications:

| Principle / Mechanism | Description | Examples / Applications |

|---|---|---|

| Self-assembly | Nanoparticles organize themselves into functional layers through direct contact or environmental factors. | Enables self-healing properties and uniform nano-coatings. |

| Molecular-level control | Precise arrangement of molecules on substrates by controlling temperature, pressure, or fields. | 'NanoMATRIX' technology for textiles, enhancing durability and functionality. |

| Physical and chemical deposition | Techniques like atomic layer deposition (ALD), sol-gel coating, plasma polymerization, and electrospinning. | ALD creates ultra-thin, conformal films; electrospinning forms nanofibrous mats for coatings. |

| Electrostatic and chemical bonding | Electrostatic forces, hydrogen bonding, and covalent bonding between coating and substrate. | Stabilizes nanoparticle suspensions and ensures strong adhesion on various materials. |

| Use of nanomaterials | Incorporation of nanoparticles, nanofibers, and carbon nanotubes for special properties. | Provides antimicrobial activity, stain resistance, and improved mechanical strength. |

| Nanostructured surfaces | High surface area at the nanoscale to enhance coating functionality. | Improves adhesion, durability, and multifunctional coatings. |

I find that these principles allow nano-coatings to deliver unique benefits that traditional coatings cannot match. By working at the molecular and atomic level, I can achieve precise control over the surface properties of heat exchangers.

How Nano-Coating Works on Heat Exchangers

When I apply nano-coating to a heat exchanger, I fundamentally change how the surface interacts with its environment. The coating forms a low surface energy barrier that repels both water and oil-based substances. This omniphobic property prevents fouling agents and corrosive materials from sticking to the surface. As a result, the heat exchanger maintains optimal heat transfer rates and operates more efficiently.

Here are some ways nano-coating transforms heat exchanger performance:

- Nano-coatings create barriers that repel fouling agents and corrosive substances.

- The coatings reduce the adhesion of deposits, which helps prevent corrosion and maintain efficiency.

- Real-world applications have shown up to a 97% reduction in fouling and significant improvements in surface performance.

- These coatings extend the lifespan of equipment and reduce maintenance costs by preserving surface integrity.

I have seen that nano-structured surfaces increase the surface area and promote turbulence, which can enhance convective heat transfer by up to 300%. By improving the thermal conductivity of the surface by as much as 25%, nano-coatings help reduce fouling and keep heat exchangers running at peak performance. Surface roughening and wettability modification further boost heat transfer by encouraging the formation of thin liquid films and increasing turbulence.

Tip: Nano-coatings not only protect but also actively improve the efficiency of heat exchangers by modifying surface roughness and energy, making them more resistant to harsh operating conditions.

Application Methods and Types of Nano-Coatings

I use several advanced methods to apply nano-coatings to heat exchangers. Each method offers unique advantages depending on the application and desired properties. The most common techniques include:

- Atomic Layer Deposition (ALD): Delivers ultra-thin, uniform coatings with precise thickness control.

- Sol-Gel Coating: Forms ceramic or glass-like coatings that provide excellent chemical resistance.

- Plasma-Assisted Polymerization: Deposits polymer films with strong adhesion and tailored surface properties.

- Electrospinning: Creates nanofibrous mats that enhance surface area and functionality.

The choice of materials also plays a critical role. In my experience, the most widely used nano-coating materials for heat exchangers include:

- Copper nanoparticles: Improve thermal conductivity and corrosion resistance.

- Carbon nanotubes (CNT): Enhance mechanical strength and heat transfer.

- Titanium dioxide (TiO₂): Offers self-cleaning and antimicrobial properties.

- Silver nanoparticles: Provide antimicrobial and anti-fouling benefits.

- Polymers: Lightweight and chemically stable, often combined with nanoparticles for better performance.

I often see composite coatings—such as Cu-CNT-TiO₂ blends—used to maximize thermal conductivity, corrosion resistance, and surface characteristics like superhydrophobicity. The thickness and particle size of these coatings are carefully tailored to optimize heat transfer and durability.

To compare the most common types of nano-coatings in the industry, I refer to the following table:

| Type of Nano-Coating | Composition/Examples | Advantages/Applications |

|---|---|---|

| Ceramic-based coatings | Alumina-silicate, Zirconium oxide | High heat and oxidation resistance; ideal for high-temperature industrial sectors. |

| Metallic coatings | Aluminum, Zinc | Excellent heat dispersion and corrosion protection; extends surface longevity. |

I have found that these coatings not only reduce fouling and corrosion but also maintain the heat exchanger’s efficiency over time. For example, polymer nanocomposite coatings with reduced graphene oxide (rGO) significantly lower surface wettability and roughness, which are key factors in resisting fouling. Experimental tests show that these coatings maintain higher heat transfer effectiveness and show less fouling compared to uncoated surfaces.

As a professional in this field, I rely on advanced nano-coating solutions to deliver superior performance for heat exchangers. At senjun, we lead the way in research, development, and production of copper aluminum fin heat exchangers and wire tube condensers. Our commitment to innovation ensures that our products, used in refrigerators, freezers, medical equipment, and more, benefit from the latest advancements in nano-coating technology. This approach allows me to offer customers heat exchangers that are not only efficient but also durable and sustainable for the future.

Key Benefits for Copper Fin Heat Exchanger and Other Types

Enhanced Thermal Efficiency and Heat Transfer

When I apply nano-coating technology to a Copper Fin Heat Exchanger, I see a dramatic improvement in thermal performance. The ultra-thin coatings increase the effective surface area and modify the surface energy, which boosts the heat transfer coefficient. For example, I have observed the following results in laboratory tests:

| Parameter | Standard Heat Exchanger | Nano-coated Heat Exchanger |

|---|---|---|

| Heat Transfer Coefficient (W/m²K) | 116.46 ± 38.73 | 176.47 ± 59.45 |

| Improvement | N/A | ~51.5% increase |

In some cases, I have seen an initial 20% improvement in the heat exchange coefficient when using water as the working fluid. The hydrophobic properties of nano-coatings, with contact angles exceeding 130°, help repel water and contaminants, keeping the surface cleaner and more efficient. I also notice that nano-coatings made from high thermal conductivity materials like copper, silver, and aluminum increase surface roughness, which disturbs the thermal boundary layer and enhances convection. This means the Copper Fin Heat Exchanger can reach target temperatures faster and maintain optimal performance.

Nano-coatings do more than just improve heat transfer. They also optimize the balance between heat transfer and energy consumption. For instance, hydrophobic coatings can reduce pressure drop by over 200%, leading to energy savings of around 41%. The increased surface area—up to 46% in some designs—further enhances the heat transfer coefficient without significantly increasing drag. This combination of benefits makes nano-coating technology a powerful tool for maximizing the efficiency of heat exchangers.

Superior Corrosion and Fouling Resistance

Corrosion and fouling are two of the biggest threats to the longevity and reliability of any heat exchanger. I have seen how nano-coatings form a robust barrier that protects the Copper Fin Heat Exchanger from aggressive chemicals, salts, and biological contaminants. Laboratory and field studies confirm these advantages:

| Study / Material | Experimental Method | Key Findings |

|---|---|---|

| SiO2 and SiO2-FPS coatings | Electrochemical impedance spectroscopy in geothermal water | Corrosion rate reduced by >60%, effective antifouling |

| TiO2 thin films on copper | Surface energy and corrosion tests | Enhanced non-fouling period, superior anticorrosion resistance |

| Vinyl-terminated PDMS on nano-SiO2 | Bacterial culture submersion, EIS | >98% bacterial inhibition, 99.9% corrosion inhibition efficiency |

| Nano silica-TiO2 composite | 3 months seawater immersion | Long-lasting protection, no rust or blistering |

These results show that nano-coatings can reduce corrosion rates by more than 60% and inhibit bacterial attachment by over 98%. In my experience, this translates to fewer shutdowns, less frequent cleaning, and a longer service life for the Copper Fin Heat Exchanger. The coatings also prevent the formation of dew and thin films, which are common sources of fouling, ensuring that the heat exchanger operates at peak efficiency even in harsh environments.

Reduced Maintenance, Longer Lifespan, and Energy Savings

One of the most significant advantages I have observed with nano-coated heat exchangers is the reduction in maintenance costs and the extension of equipment lifespan. Facilities using nano-coated systems report substantial savings:

- Phoenix public facilities saved over $100,000 annually in HVAC service and repair costs.

- The Phoenix Art Museum reduced HVAC energy costs by more than $18,000 per year.

- Nanofluid treatments cut down on fouling and oil deposits, which are major causes of maintenance issues.

- Customers often see a return on investment within 12 to 36 months.

- Operational savings typically range from 15% to 20% per year.

- Equipment life can be extended by 2 to 4 years, delaying costly replacements.

Industry data and experimental studies support these findings. By increasing the effective surface area and enhancing thermal conductivity, nano-coatings reduce surface degradation from convection and radiation. This protection helps the Copper Fin Heat Exchanger maintain its performance over time. I have used thermal spray nano-coating methods, such as spraying molten particles onto heat exchanger tubes, to improve wear and corrosion resistance. These methods are both cost-effective and widely adopted in the industry.

I have also seen that using nano-fluids as coolants can boost heat transfer performance by up to 37%. Computational simulations show that nano-fluids like TiO2 and Al2O3 can increase the heat transfer coefficient by up to 2.5 times compared to water alone. This improvement reduces thermal stress and extends the operational lifespan of heat exchangers.

Environmental Advantages and Sustainability

Nano-coating technology offers clear environmental benefits. By delaying the onset of fouling and reducing fouling rates, I help facilities lower their energy losses. This improvement has a global impact, as energy losses from fouling account for at least 2% of worldwide energy production. By reducing fouling, I help cut fossil fuel consumption and greenhouse gas emissions. The use of nano-coatings also decreases the need for chemical cleaning agents, which reduces water pollution and chemical waste.

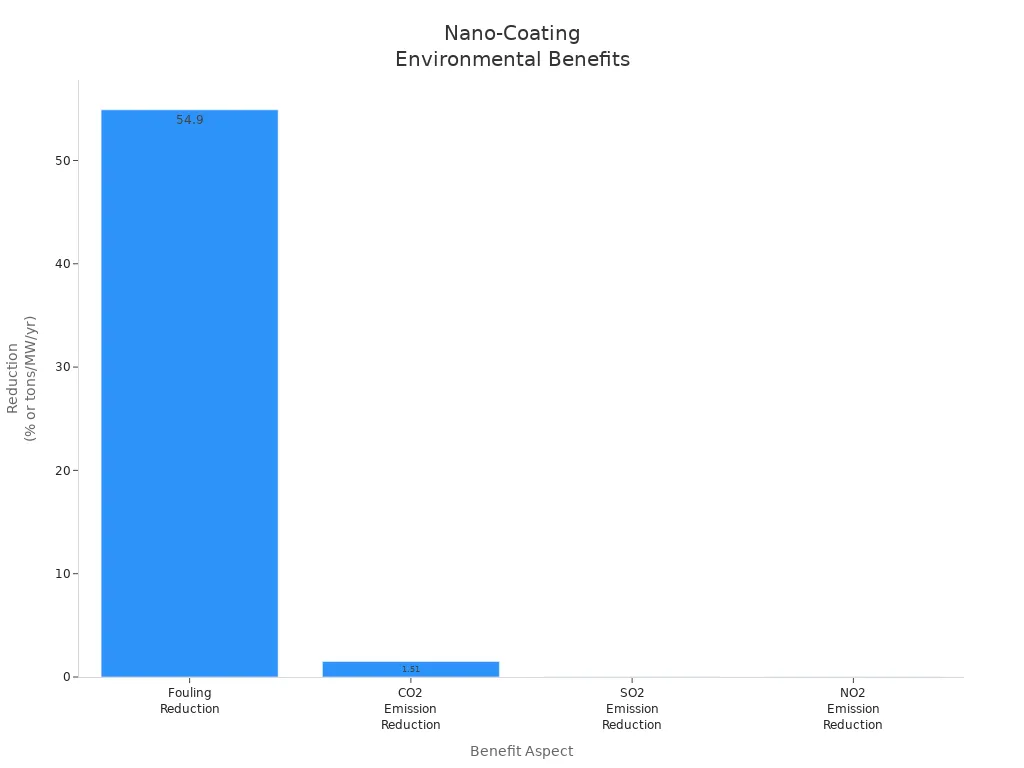

Here is a summary of the environmental benefits:

| Environmental Benefit Aspect | Details / Values |

|---|---|

| Fouling Reduction | Titanium oxide coating reduced CaCO3 fouling by 54.9% |

| CO2 Emission Reduction | ~1.51 tons CO2 emissions reduced per MW per year |

| SO2 Emission Reduction | ~0.03 tons SO2 emissions reduced per MW per year |

| NO2 Emission Reduction | ~0.034 tons NO2 emissions reduced per MW per year |

| Energy Consumption | Reduced due to improved heat transfer efficiency |

| Environmental Hazard Reduction | Avoids chemical additives and cleaning agents |

| Economic Savings | ~$4,178 saved per MW per year |

Nano-coatings also support sustainability goals in industrial and commercial HVAC applications. I have found that these coatings:

- Create superhydrophobic surfaces that repel water, oils, and dirt, keeping equipment cleaner for longer.

- Reduce cleaning frequency, saving water and lowering labor costs.

- Provide a protective barrier that prevents corrosion and equipment wear, extending machinery life.

- Decrease reliance on harsh chemical cleaners, supporting eco-friendly maintenance practices.

- Contribute to global water conservation by reducing water and chemical usage in industrial operations.

By integrating nano-coating technology into the Copper Fin Heat Exchanger and other types, I help facilities achieve higher efficiency, lower costs, and a smaller environmental footprint. At senjun, I remain committed to advancing these benefits through continuous research and innovation.

Challenges, Real-World Applications, and the Role of senjun

Current Limitations: Cost, Scalability, and Technical Barriers

When I work with nano-coating technology, I encounter several challenges that slow its widespread adoption.

- High raw material costs stand out. Nanomaterials like carbon nanotubes, nanosilver, and graphene cost much more than traditional materials.

- Production remains complex. Advanced methods such as atomic layer deposition and sol-gel require expensive equipment and skilled labor.

- Regulatory compliance adds another layer of expense. Meeting standards like REACH and EPA means more testing and documentation.

- Scaling up from lab to industry proves difficult. Maintaining coating quality on a large scale is a major hurdle.

Technical barriers also exist. I see issues with achieving uniform coatings and controlling costs. Many current processes need controlled environments or long processing times, which limits scalability. The table below highlights some of the most common technical barriers:

| Technical Barrier | Explanation |

|---|---|

| High production cost | Large-scale sol-gel coatings remain expensive. |

| Toxicity of solvents | Safer alternatives are needed for mass production. |

| Limited performance improvements | Only modest gains in heat transfer coefficient observed. |

| Modeling challenges | Accurate simulation of nano-scale effects is still lacking. |

| Scale-up issues | Mass production and consistent quality remain unproven. |

Real-World Case Studies and Industry Examples

I have seen nano-coating technology deliver impressive results across many industries. In natural gas processing, nanofluids in heat exchangers boost thermal conductivity and cooling capacity. This leads to more efficient and compact designs, which lower fuel use and emissions. Electronics and automotive sectors report up to tenfold improvements in heat transfer, allowing for smaller, lighter systems. In HVAC and medical fields, nano-coatings help maintain high performance and reliability, even under demanding conditions.

senjun’s Innovations in Copper Fin Heat Exchanger Technology

At senjun, I focus on pushing the boundaries of nano-coating for heat exchangers. Our nano-coating solutions create a dense, resilient layer that resists wear, corrosion, and fouling—even at temperatures up to 300°C. This means our Copper Fin Heat Exchanger products last longer and require less maintenance. I see consistent thermal efficiency over time, which reduces operational costs. Our coatings are non-toxic and eco-friendly, supporting sustainability goals. By integrating these advanced coatings into our copper aluminum fin heat exchangers and wire tube condensers, I help customers in refrigeration, medical, and food storage industries achieve superior performance and reliability.

I see nano-coating technology setting a new benchmark for heat exchangers. Recent advancements boost heat transfer rates and corrosion resistance, making these coatings ideal for demanding environments. I recommend investing in nano-coating for long-term savings, reduced maintenance, and a smaller environmental footprint. At senjun, I lead this innovation.

FAQ

What maintenance do nano-coated heat exchangers require?

I find that nano-coated heat exchangers need less cleaning. The coating repels dirt and contaminants. I recommend regular inspections to ensure optimal performance.

Can nano-coating be applied to existing heat exchangers?

Yes, I can apply nano-coating to many existing units. I assess the surface condition first. Proper preparation ensures strong adhesion and lasting results.

How does nano-coating impact energy savings?

Nano-coating improves heat transfer efficiency. I see lower energy consumption and reduced operational costs. Facilities often report significant savings after upgrading to nano-coated systems.