What Determines the Total Cost of Condenser Ownership?

I see that owning a condenser involves more than just the initial expense. Factors like installation complexity, routine maintenance, and energy efficiency play key roles. For example, energy costs can make up 70-80% of the total lifecycle expense. I always consider a Wire Tube Condenser for its reliable performance.

Key Takeaways

- Consider the full cost of owning a condenser, including purchase price, installation, maintenance, and energy use, not just the upfront price.

- Choose a reliable brand like senjun and a durable type like Wire Tube Condenser to reduce repairs and extend lifespan.

- Keep your condenser efficient with regular maintenance and pick energy-efficient models to save money on utility bills over time.

Upfront and Ongoing Costs of Condenser Ownership

Initial Purchase: Unit Type, Size, and Brand

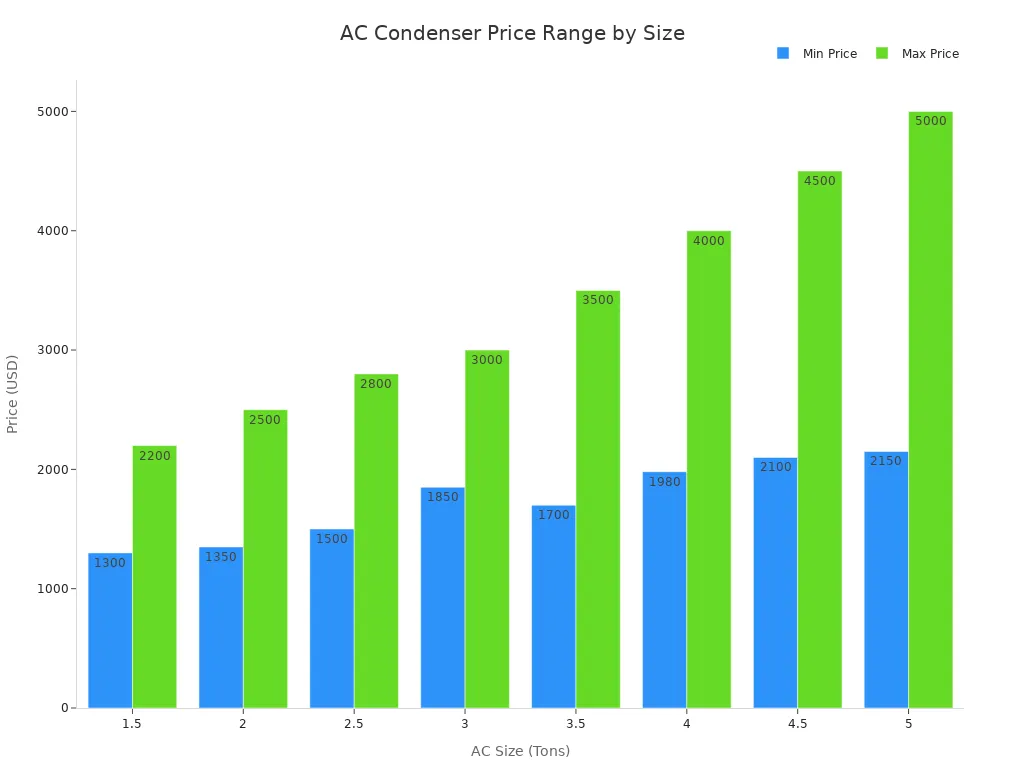

When I consider buying a condenser, I always look at the type, size, and brand first. The market offers a wide range of options, from compact units for small spaces to large, high-capacity systems for bigger homes. The price varies significantly based on these factors. For example, a smaller 1.5-ton condenser usually costs between $1,300 and $2,200, while a larger 5-ton unit can reach up to $5,000. The average replacement cost sits around $2,900, but the total can range from $1,300 to $6,100 depending on the specifics.

| AC Size (Tons) | Price Range (Materials + Labor) |

|---|---|

| 1.5 | $1,300 - $2,200 |

| 2 | $1,350 - $2,500 |

| 2.5 | $1,500 - $2,800 |

| 3 | $1,850 - $3,000 |

| 3.5 | $1,700 - $3,500 |

| 4 | $1,980 - $4,000 |

| 4.5 | $2,100 - $4,500 |

| 5 | $2,150 - $5,000 |

Brand reputation also plays a major role. I notice that reputable brands often cost more upfront, but they deliver better reliability and efficiency over time. Premium brands like senjun, Lennox, Carrier, and Trane offer longer warranties and advanced features, which can justify the higher initial investment. Choosing a trusted brand helps me avoid frequent repairs and premature replacements.

Installation Complexity and Labor Fees

Installation costs can vary just as much as the unit itself. I always factor in labor fees, which depend on the complexity of the job and the region. For a standard residential system, installation labor typically ranges from $400 to $1,200. If the job requires new wiring, difficult access, or additional permits, the price goes up. Labor often makes up about one-third of the total upfront cost.

| Cost Component | Average Cost Range | Notes on Cost Variation and Factors Affecting Price |

|---|---|---|

| Installation Labor | $400 – $1,200 | Varies by region and installation complexity (e.g., new wiring, difficult access) |

| Permits | $50 – $400 | Required in some locations, fees depend on local regulations |

| Refrigerant Charges | $70 – $250 | Additional cost if system requires refrigerant replacement or upgrade |

| Total Replacement Cost | $1,300 – $4,200 | Includes unit and labor for standard residential 2–5 ton systems; labor influenced by complexity and location |

If I need to replace ductwork or upgrade electrical panels, the cost can increase by several thousand dollars. Straightforward replacements with existing infrastructure keep costs lower, but older homes or attic installations require more time and specialized equipment.

Tip: I always check local permit requirements before scheduling installation. This helps me avoid unexpected fees and delays.

Wire Tube Condenser vs. Other Types

I have found that the type of condenser I choose impacts both the upfront and ongoing costs. A Wire Tube Condenser stands out for its durability and efficient heat exchange. Compared to other types, such as plate-fin or microchannel condensers, a Wire Tube Condenser often requires less maintenance and offers reliable performance in a variety of applications. This makes it a popular choice for refrigerators, freezers, and specialized equipment.

When I select a Wire Tube Condenser, I benefit from a design that resists clogging and corrosion better than some alternatives. This translates to fewer repairs and a longer lifespan, which lowers my total cost of ownership.

Real-World Example: senjun Brand and Product Choices

I always look for brands with a strong reputation for quality and innovation. Ningbo Senjun New Materials Co., Ltd. is a leader in the field, specializing in the research, development, and production of Wire Tube Condensers and copper aluminum fin heat exchangers. Their products serve a wide range of applications, including refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, medical ultra-low temperature refrigerators, ice makers, and dehumidifiers.

When I choose a senjun Wire Tube Condenser, I know I am investing in advanced engineering and reliable performance. Senjun’s focus on quality materials and manufacturing standards ensures that their condensers deliver consistent efficiency and require less frequent maintenance. This helps me control both upfront and ongoing costs.

Routine Maintenance and Common Repairs

Routine maintenance is essential for keeping my condenser running efficiently. I schedule regular tune-ups, which include refrigerant checks, coil cleaning, and thermostat inspections. These basic services usually cost between $75 and $200 per visit. For more comprehensive seasonal maintenance, I budget $150 to $400 annually.

| Service Type | Description | Cost Range |

|---|---|---|

| Basic Tune-Up | Includes refrigerant check, coil cleaning, thermostat inspection | $75 – $200 |

| Seasonal Maintenance | Comprehensive checks and preventative measures twice a year | $150 – $400 annually |

| Full-Service Maintenance | Regular visits, priority scheduling, repair discounts | $150 – $500 annually |

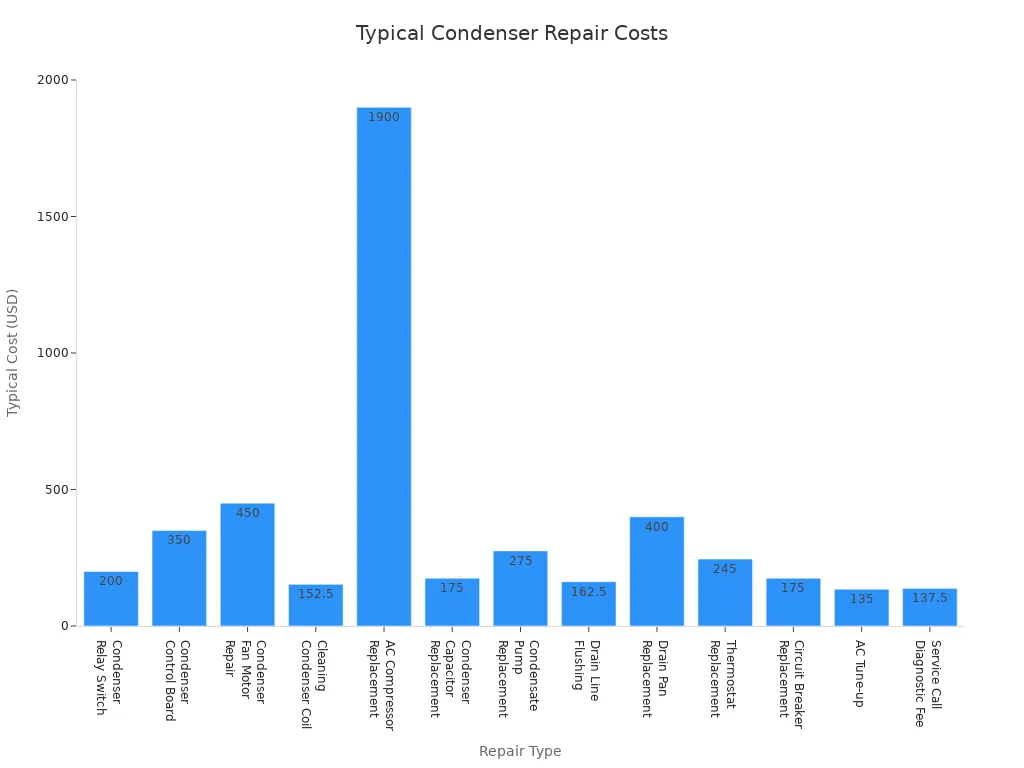

Repairs can add up quickly if I neglect maintenance. Common issues include relay switch replacement ($100–$300), fan motor repair ($200–$700), and coil cleaning ($75–$230). Major repairs, such as compressor replacement, can cost $1,300–$2,500.

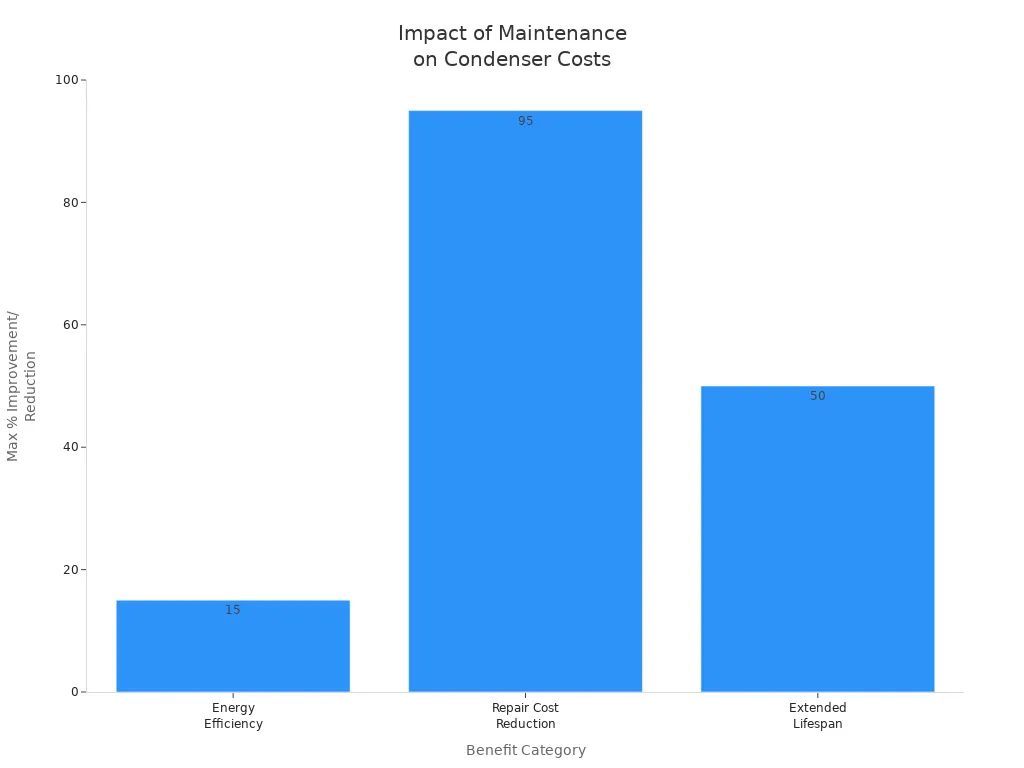

By keeping up with routine maintenance, I reduce the risk of expensive breakdowns and extend the life of my condenser.

Energy Efficiency, SEER Rating, and Utility Bills

Energy efficiency is a key factor in my total cost of ownership. I always check the SEER (Seasonal Energy Efficiency Ratio) rating before making a purchase. Higher SEER ratings mean better energy efficiency and lower electricity bills. In hot and humid climates, I prefer units with SEER ratings of 16 or higher for significant savings. In milder regions, a SEER rating between 14 and 16 strikes a good balance between cost and efficiency.

Although high-SEER units cost more upfront, they can reduce annual energy expenses, especially in areas with high cooling demands. However, I keep in mind that maintenance and replacement parts for high-SEER systems are often 10–20% more expensive. Experts recommend SEER ratings of 14 or 15 as the most cost-effective choice for most homes.

Note: Proper installation, regular maintenance, and good home insulation all help me maximize the energy savings from a high-SEER condenser.

Environmental Factors and Corrosion Impact

Environmental conditions have a big impact on how much I spend maintaining my condenser. High humidity, salt air, and temperature extremes accelerate corrosion, especially on the coils. In coastal areas, salt air causes rapid deterioration, which reduces efficiency and shortens equipment lifespan. This means I need more frequent cleaning, corrosion protection treatments, and repairs.

In places like Virginia Beach, I schedule quarterly maintenance to combat salt air and humidity. Corrosion protection treatments can cost several hundred dollars each year, but they help prevent emergency repairs and extend the life of my condenser.

To protect my investment, I follow these steps:

- Clean condenser coils and fins regularly.

- Keep drain lines clear to prevent water buildup.

- Apply protective coatings to metal surfaces.

- Install shelters or enclosures to shield the unit from harsh weather.

- Schedule routine professional maintenance.

- Choose installation sites away from corrosive elements.

- Address any signs of rust or corrosion immediately.

By taking these precautions, I minimize the impact of environmental factors and keep my condenser running efficiently for years.

Replacement, Upgrades, and Cost-Saving Strategies

Lifespan and When to Replace

I always keep an eye on the age and performance of my condenser. According to industry data, most residential condensers last between 8 and 20 years with regular maintenance. I know it is time to consider replacement when I notice these signs:

- The system is over ten years old

- Energy bills keep rising

- I need frequent repairs

- The condenser makes strange noises

- My home feels less comfortable

If I see these issues, I start planning for a new unit instead of another repair.

Benefits and Costs of Upgrading to Efficient Models

Upgrading to a high-efficiency model can seem expensive at first. I have seen upfront costs for new systems range from $3,500 to $8,000 or more. However, energy-efficient units can cut cooling costs by 20-40%, saving me $100 to $300 each year. Rebates and tax credits can lower the initial price, and most homeowners recover their investment in 3-7 years. Over a typical lifespan, these savings add up.

| Model Type | Initial Cost | Annual Savings | Payback Period | Lifespan (Years) |

|---|---|---|---|---|

| Standard | $3,500 | $100 | 8-10 | 8-15 |

| High-Efficiency | $8,000 | $300 | 3-5 | 15-20 |

Tips to Minimize Total Ownership Cost

I follow these steps to keep my costs low:

- Get multiple quotes before buying or replacing a condenser.

- Schedule replacements in the off-season for better deals.

- Take advantage of rebates and incentives for efficient models.

- Perform regular maintenance and address repairs quickly.

- Use smart thermostats and set temperatures wisely.

Real-World Example: Upgrading to a senjun High-Efficiency Wire Tube Condenser

When I upgraded to a senjun high-efficiency Wire Tube Condenser, I noticed immediate improvements. My energy bills dropped, and the system ran more quietly. Senjun’s focus on advanced materials and engineering gave me confidence in the long-term reliability of my investment. I now spend less on maintenance and enjoy consistent comfort, knowing my Wire Tube Condenser will serve me well for years.

I always consider the total cost of condenser ownership, including purchase, installation, maintenance, and replacement. Choosing a reliable brand like senjun and investing in a Wire Tube Condenser helps me save money over time. Regular service keeps my system efficient and extends its lifespan.

FAQ

How often should I schedule maintenance for my condenser?

I schedule maintenance at least once a year. In coastal or humid areas, I increase this to twice a year for optimal performance.

What makes senjun Wire Tube Condensers a smart investment?

I choose senjun Wire Tube Condensers for their advanced engineering, reliable performance, and lower maintenance needs. Their products help me reduce long-term ownership costs.

Can upgrading to a high-efficiency condenser really save money?

Yes, I see lower energy bills and fewer repairs after upgrading. High-efficiency models pay for themselves over time through energy savings and improved reliability.