Titanium in Heat Exchangers: Performance vs. Cost Challenges

I often see titanium chosen for Heat Exchangers due to its exceptional properties. Its corrosion resistance and durability outperform most alternatives, even in extreme environments. However, I understand why decision-makers hesitate. The initial costs can be steep compared to options like acopper fin heat exchanger, which offers a more cost-effective solution.

Key Takeaways

- Titanium heat exchangers work well in tough conditions. They resist rust and last long, making them great for chemical plants and seawater Cooling Systems.

- Even though they cost more at first, titanium saves money over time. They need less fixing and last longer, which is good for industries needing dependable tools.

- For cheaper options, try senjun's copper aluminum fin heat exchangers. They work well and cost less.

Why Titanium? Key Properties for Heat Exchangers

Corrosion Resistance in Harsh Environments

I’ve always been impressed by titanium’s ability to resist corrosion, even in the most aggressive environments. Its performance in seawater, acidic solutions, and high-temperature conditions makes it a standout material for heat exchangers. Laboratory tests confirm this. For instance:

- Titanium exhibits a corrosion rate of just 1.2 mpy (0.031 mm/y) in a 0.7% ferric chloride solution.

- It remains resistant to acetic acid at temperatures up to 400°F (204°C).

- In sulphide-rich environments, titanium withstands up to 500°F (260°C) without forming harmful scales.

This resilience ensures reliable performance and reduces maintenance needs, even in demanding applications like chemical processing or seawater cooling systems.

High Strength-to-Weight Ratio

Titanium’s strength-to-weight ratio is another reason I recommend it for heat exchangers. It offers tensile strength ranging from 210 to 1380 MPa, far surpassing aluminum’s 70 to 700 MPa. Despite being denser than aluminum, titanium’s strength is nearly double, making it ideal for applications requiring lightweight yet robust materials. This property is particularly valuable in industries like aerospace, where weight reduction is critical without compromising durability.

Thermal Conductivity and Heat Transfer Efficiency

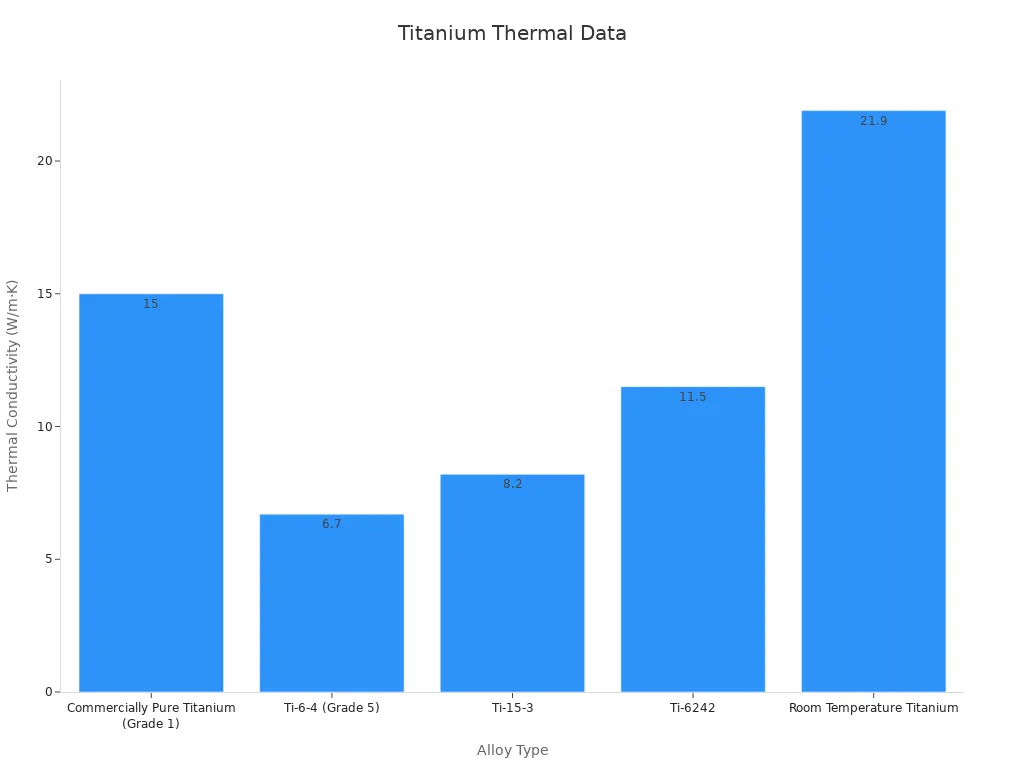

While titanium’s thermal conductivity isn’t as high as copper, it still performs efficiently in Heat Transfer applications. Here’s a comparison of thermal conductivity values for various titanium alloys:

| Alloy Type | Thermal Conductivity (W/m·K) |

|---|---|

| Commercially Pure Titanium (Grade 1) | 15 |

| Ti-6-4 (Grade 5) | 6.7 |

| Ti-15-3 | 8.2 |

| Ti-6242 | 11.5 |

| Room Temperature Titanium | 21.9 |

These values demonstrate titanium’s ability to balance strength and thermal efficiency, making it a reliable choice for heat exchangers.

Longevity and Durability

Titanium’s longevity is unmatched. Its resistance to corrosion, combined with its strength, ensures a long service life even under extreme conditions. For example, titanium heat exchangers can withstand high pressures and temperatures without failure. This durability translates to fewer replacements and lower lifecycle costs, which I find particularly appealing for industries focused on long-term value.

Performance Comparison: Titanium vs. Other Materials

Stainless Steel: Cost-Effective but Limited in Corrosion Resistance

When I compare titanium to stainless steel, the differences in corrosion resistance stand out. Stainless steel is a popular choice for heat exchangers due to its affordability and adequate performance in less corrosive environments. Industries like chemical processing and HVAC often rely on stainless steel for its cost-effectiveness. However, its limitations become apparent in harsher conditions.

- Titanium resists corrosion in seawater and chloride-rich environments, while stainless steel is prone to pitting and crevice corrosion.

- In polluted seawater, titanium shows no signs of corrosion even after 16 years, whereas stainless steel struggles to maintain integrity.

- Titanium performs reliably at high temperatures (up to 500°F) and velocities (up to 120 ft/sec), conditions that challenge stainless steel.

Although stainless steel remains a cost-effective option for mild environments, I find titanium indispensable for applications requiring long-term durability and minimal maintenance in aggressive settings.

Copper Fin Heat Exchanger: High Conductivity but Prone to Corrosion

Copper fin heat exchangers excel in thermal conductivity. Copper’s ability to transfer heat efficiently makes it a preferred material in many applications. Its thermal conductivity of 231 Btu/(hr-ft-F) surpasses most metals, including aluminum and stainless steel. This high conductivity ensures rapid heat transfer, which is critical in systems requiring efficient thermal management.

However, copper’s susceptibility to corrosion limits its use in certain environments. Fluids in heat transfer systems can accelerate corrosion, leading to frequent maintenance and reduced lifespan. Titanium, on the other hand, offers a compelling alternative. Its corrosion resistance ensures consistent performance, even in environments where copper would degrade. While copper fin heat exchangers remain a cost-effective solution for less demanding applications, I recommend titanium for environments where reliability and longevity are paramount.

Aluminum: Lightweight but Less Durable

Aluminum’s lightweight nature makes it an attractive option for heat exchangers, especially in industries like automotive and aerospace. Its lower density reduces overall system weight, which can improve efficiency and reduce operational costs. However, aluminum’s durability falls short when compared to titanium.

- Titanium exhibits superior fatigue resistance, maintaining its strength under repeated cyclic loads.

- Aluminum tends to lose strength more quickly in similar conditions, making it less suitable for applications requiring long-term durability.

- In harsh environments, titanium’s resilience ensures a longer service life, while aluminum may require frequent replacements.

Although aluminum’s lightweight properties are advantageous, I find titanium’s durability and reliability more appealing for demanding applications.

How Titanium Outperforms in Extreme Conditions

Titanium’s performance in extreme conditions sets it apart from other materials. I’ve seen its effectiveness in high-pressure and high-temperature environments, where other materials often fail. For example, studies on titanium heat exchangers using TiO2 nanofluid reveal impressive results. Key findings include:

- A 25%-29% decrease in exchanger effectiveness when the heat capacity ratio approaches unity, despite enhancements in overall heat transfer.

- A 16.5%-25.5% improvement in effectiveness when switching from parallel to counterflow configurations.

These results highlight titanium’s adaptability and efficiency in challenging scenarios. Its ability to maintain mechanical stability and resist corrosion under extreme conditions makes it the material of choice for critical applications like power generation and chemical processing.

When I evaluate materials for heat exchangers, titanium consistently outperforms alternatives in environments where reliability, durability, and efficiency are non-negotiable.

Cost Challenges of Titanium in Heat Exchangers

High Initial Investment Costs

The high upfront cost of titanium heat exchangers often deters many businesses, especially small and medium-sized enterprises. Compared to alternatives like stainless steel or copper, titanium demands a significantly larger initial investment.

- Titanium’s price per pound far exceeds that of stainless steel or copper.

- Plate and tube heat exchangers made from titanium require substantial capital, limiting their adoption in cost-sensitive industries.

For example, small enterprises in the HVAC or refrigeration sectors often opt for more affordable materials like stainless steel or copper fin heat exchangers. While these alternatives may suffice in less demanding environments, they lack the long-term durability and corrosion resistance of titanium.

Note: The initial cost of titanium is about 50% higher than Copper-Nickel units. However, its extended service life often offsets this expense over time.

Manufacturing and Fabrication Complexity

Titanium’s unique properties make it challenging to manufacture and fabricate. Its high melting point and reactivity with oxygen require specialized equipment and techniques, which drive up production costs.

| Metal | Cost (per lb of powdered material) | SolidWorks Simulation Performance |

|---|---|---|

| Titanium | $100 | High heat transfer |

| Stainless Steel | $7.50 | Medium Heat Transfer |

Advanced methods like additive manufacturing have streamlined some processes. For instance, producing manifold-microchannel heat exchangers as a single unit eliminates the need for assembly. This approach is particularly advantageous for titanium, as it allows for intricate designs that enhance performance. However, the high cost of maintaining these machines and the expertise required to operate them remain significant barriers.

Additionally, techniques like directed energy deposition reduce material waste and speed up production. Yet, these methods still demand substantial investment in equipment and skilled labor, further increasing the overall cost of titanium heat exchangers.

Maintenance and Lifecycle Cost Considerations

While titanium heat exchangers require a higher initial investment, their maintenance costs are relatively low. Titanium’s exceptional corrosion resistance minimizes the need for frequent repairs or replacements. For example, in marine environments, titanium units can last the entire 20-year lifespan of a yacht without requiring replacement.

In contrast, materials like Copper-Nickel often need replacement every 4-7 years due to corrosion. This frequent maintenance not only increases costs but also disrupts operations. By choosing titanium, industries can reduce downtime and maintenance expenses, ensuring consistent performance over the long term.

Tip: Although titanium’s upfront cost is higher, its reduced maintenance needs and extended lifespan make it a cost-effective choice for industries prioritizing reliability and efficiency.

Balancing Cost with Long-Term Value

When evaluating the cost-effectiveness of titanium heat exchangers, I always consider their long-term value. The return on investment (ROI) for titanium often surpasses that of other materials after just a few years of service.

- Titanium’s durability eliminates the need for frequent replacements, reducing overall costs.

- Its resistance to extreme conditions ensures consistent performance, preventing costly system failures.

- Over a 20-year period, titanium heat exchangers prove more economical than Copper-Nickel units, despite their higher initial cost.

For industries like chemical processing or power generation, where reliability is critical, titanium offers unparalleled value. By investing in titanium, businesses can achieve significant savings in maintenance and replacement costs while ensuring optimal performance.

Applications Where Titanium Shines

Seawater Cooling Systems

I’ve seen titanium excel in seawater cooling systems, where corrosion resistance is critical. Its ability to withstand hot aerated seawater at temperatures up to 650 ºC makes it indispensable for marine applications. Unlike high-alloy stainless steels, which often suffer localized corrosion in chlorinated seawater, titanium maintains its integrity throughout its service life.

Key operational data further validates titanium’s performance:

| Aspect | Details |

|---|---|

| Material | ASTM B265 Grade 1 (commercially pure titanium) |

| Thickness | 0.6 mm |

| Operation Duration | Approximately 126,000 hours of operation |

| Failure Cause | Mechanical fatigue, indicated by striations, ratchet marks, and transgranular crack propagation |

| Observations | Through-wall cracks found on sealing surfaces inside the double gasket area |

| Operating Conditions | Inlet seawater temperature: 29 °C; Outlet fresh water temperature: 32 °C; Pressure: 0.3-0.8 MPa |

This data highlights titanium’s reliability in demanding marine environments, ensuring extended service life and reduced downtime due to equipment failure.

Chemical Processing and Petrochemical Industries

Titanium’s role in chemical processing and petrochemical industries continues to grow. Its resistance to aggressive chemical brines and polluted waters makes it a preferred material for heat exchangers in oil refineries and offshore extraction processes. I’ve observed its effectiveness firsthand in these environments, where other materials often fail.

- Titanium heat exchangers account for 47.3% of chemical titanium equipment applications.

- Plate heat exchangers, with heat transfer coefficients 2.5 to 8 times higher than tube types, reduce titanium usage per unit heat transfer area by 50%.

- Over the past decade, titanium equipment applications in the chemical industry have increased by approximately 30% annually.

These metrics demonstrate titanium’s efficiency and cost-effectiveness in chemical processing, where reliability and performance are paramount.

Power Generation and Desalination Plants

Titanium’s efficiency in power generation and desalination plants is well-documented. I’ve reviewed studies confirming its outstanding corrosion resistance in desalination applications, particularly in environments with specific metallic ions in raw brine. Over a twelve-year period, titanium heat exchange tubing has delivered favorable results in multistage flash desalination plants.

| Key Findings | Description |

|---|---|

| Corrosion Resistance | Titanium exhibits outstanding corrosion resistance in desalination applications due to specific metallic ions in raw brine and its metallurgical texture. |

| Operational Performance | Over a twelve-year period, titanium heat exchange tubing has shown favorable performance in two multistage flash desalination plants, confirming its efficiency. |

| Material Suitability | The study concludes that titanium is an excellent material for condenser tubing in desalination plants. |

These findings underscore titanium’s suitability for condenser tubing, ensuring reliable performance in critical applications like power generation and desalination.

Aerospace and High-Performance Applications

Titanium’s high strength-to-weight ratio makes it a cornerstone material in aerospace and high-performance applications. I’ve seen its use in aircraft heat exchangers, where weight reduction is crucial without compromising durability. Titanium’s ability to withstand extreme temperatures and pressures ensures consistent performance in demanding conditions.

In aerospace, titanium’s lightweight nature reduces fuel consumption and enhances efficiency. Its resilience under cyclic loads ensures long-term reliability, making it the material of choice for high-performance systems. Whether in jet engines or spacecraft cooling systems, titanium delivers unmatched performance, proving its value in cutting-edge applications.

senjun and Copper Aluminum Fin Heat Exchangers

About senjun: Innovating Heat Exchanger Solutions

I’ve always admired companies that push the boundaries of innovation, and senjun stands out in this regard. Ningbo Senjun New Materials Co., Ltd. specializes in the research, development, and production of advanced heat exchanger solutions. Their portfolio includes wire tube condensers and copper aluminum fin heat exchangers, which are integral to refrigeration systems like refrigerators, freezers, and medical ultra-low temperature refrigerators. Senjun’s commitment to quality and efficiency has earned them recognition across industries, from display cabinets to dehumidifiers.

Technical reviews highlight senjun’s innovative approaches. For instance, their refrigeration systems demonstrate impressive exergy efficiency and energy savings. A comparative analysis of refrigeration cycles reveals the following:

| Refrigeration Cycle | Energy Consumption (kW) | Specific Energy Consumption (kWh/kg) | Exergy Efficiency (%) | Life Cycle Cost (USD) |

|---|---|---|---|---|

| Vapor-Compression Cycle | 112.44 | 0.1898 | 38.31 | N/A |

| Linde-Hampson Cycle | 102.35 | 0.1728 | 43.03 | 2.0 million lower |

These results underscore senjun’s ability to deliver cost-effective and energy-efficient solutions, making them a trusted name in the heat exchanger industry.

Copper Aluminum Fin Heat Exchangers: A Cost-Effective Alternative

Copper aluminum fin heat exchangers offer a compelling alternative to traditional materials. I’ve seen their effectiveness in air conditioning systems, where they balance performance and affordability. Studies show that these heat exchangers achieve a copper saving ratio of 71.86% and reduce costs by 63% compared to conventional copper units. Despite the cost savings, they maintain excellent cooling and heating capacities, with negligible performance declines compared to copper heat exchangers.

This combination of efficiency and affordability makes copper aluminum fin heat exchangers ideal for applications where cost constraints are critical. Senjun’s expertise in this area ensures that their products deliver reliable performance while minimizing operational expenses.

Comparing senjun's Solutions with Titanium Heat Exchangers

When comparing senjun’s copper aluminum fin heat exchangers to titanium heat exchangers, I find distinct advantages in both. Titanium excels in extreme environments, offering unmatched durability and corrosion resistance. However, senjun’s solutions shine in cost-sensitive applications. Their copper aluminum fin heat exchangers provide high thermal efficiency and significant cost savings, making them a practical choice for industries like HVAC and refrigeration.

For example, while titanium heat exchangers dominate in marine and chemical processing environments, senjun’s copper aluminum fin units perform exceptionally well in air conditioning systems and refrigeration cycles. This versatility allows businesses to choose the right solution based on their specific needs and budget constraints.

Titanium delivers exceptional performance in heat exchangers, especially in harsh environments. Its durability and corrosion resistance often outweigh the high initial costs. I always advise decision-makers to assess their performance requirements and budget constraints. For cost-sensitive applications, senjun’s copper aluminum fin heat exchangers provide an efficient and affordable alternative.

FAQ

What makes titanium heat exchangers suitable for extreme environments?

Titanium resists corrosion, handles high temperatures, and maintains mechanical stability under pressure. These properties ensure reliable performance in demanding applications.

How does senjun innovate in heat exchanger technology?

Senjun develops copper aluminum fin heat exchangers with advanced designs. Their solutions balance efficiency, affordability, and durability for refrigeration and HVAC systems.

Are titanium heat exchangers worth the investment?

Titanium offers unmatched durability and low maintenance costs. For industries prioritizing reliability, its long-term value outweighs the initial expense.